High-elasticity low-density polyethylene foaming composite material and preparation method thereof

A technology of low-density polyethylene and composite materials, which is applied in the field of foamed composite materials, and can solve problems such as limitations, resilience not exceeding 14%, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1, raw material selection:

[0021] Low-density polyethylene, grade 2426H, Dongguan Kelong Plastic Raw Materials Co., Ltd., content 85 parts

[0022] Elastomer is selected polyethylene octene co-elastomer (POE), preferred trade mark 8180, and parts by weight are 15 parts;

[0023] Foaming agent is azodicarbonamide (AC), and parts by weight are 1.5 parts;

[0024] The foaming aid is zinc oxide (ZnO), and the parts by weight are 0.5 parts;

[0025] The crosslinking agent is dicumyl peroxide (DCP), and the parts by weight are 0.2 parts.

[0026] Step 2. Extrusion: The extrusion process is: 90°C in the first zone, 100°C in the second zone, 110°C in the third zone, 125°C in the fourth zone, 125°C in the fifth zone, and 130°C at the head; the screw speed is 40 r / min Under certain conditions, the low-density polyethylene modified material containing elastomer (POE) and crosslinking agent (DCP) is added to the twin-screw extruder, and the modified material A is o...

Embodiment 2

[0031] Step 1. Selection of raw materials: low-density polyethylene, grade 2426H, Dongguan Kelong Plastic Raw Materials Co., Ltd.,

[0032] Low density polyethylene, parts by weight are 85 parts;

[0033] Elastomer is selected polyethylene octene co-elastomer (POE), preferred trade mark 8440, and parts by weight are 15 parts;

[0034] Foaming agent is azodicarbonamide (AC), and parts by weight are 1.5 parts;

[0035] The foaming aid is zinc oxide (ZnO), and the parts by weight are 0.5 parts;

[0036] The crosslinking agent is dicumyl peroxide (DCP), and the parts by weight are 0.2 parts.

[0037] Repeat steps 2-4 in Example 1 to obtain the finished product.

[0038]

Embodiment 3

[0040] Step 1. Selection of raw materials: low-density polyethylene, grade 2426H, Dongguan Kelong Plastic Raw Materials Co., Ltd.,

[0041] Low-density polyethylene, content 85 parts;

[0042] Elastomer is selected polyethylene octene co-elastomer (POE), preferred brand 8450, and parts by weight are 15 parts;

[0043] Foaming agent is azodicarbonamide (AC), and parts by weight are 1.5 parts;

[0044] The foaming aid is zinc oxide (ZnO), and the parts by weight are 0.5 parts;

[0045] The crosslinking agent is dicumyl peroxide (DCP), and the parts by weight are 0.2 parts.

[0046] Repeat steps 2-4 in Example 1 to obtain the finished product.

[0047]

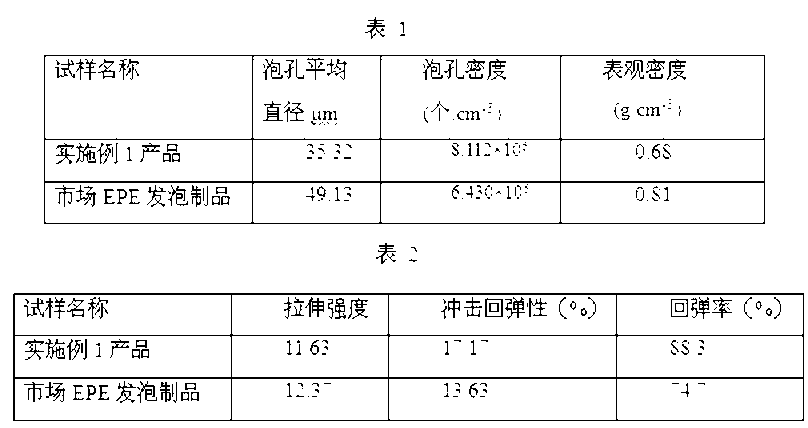

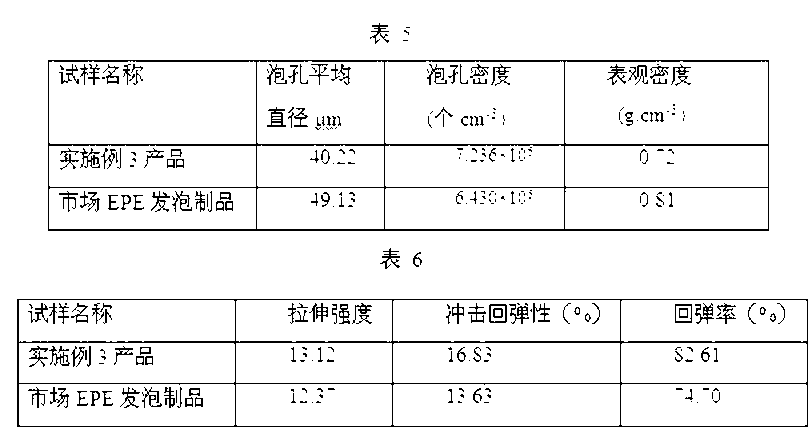

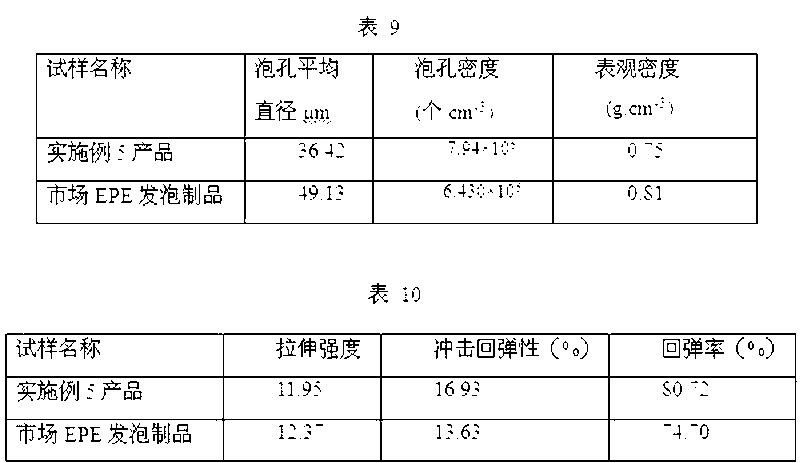

[0048] From the data in Table 1 to Table 6, it can be seen that the high-elastic low-density polyethylene foam composite products made by adding the above-mentioned proportions have ideal foaming quality, and the average cell diameter, cell diameter distribution, and cell density are obvious. It is superior to EP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com