Device and method for measuring fluorine content in metallurgical slag melting agent

A measuring device and measuring method technology, which are applied in the direction of measuring device, chemical method analysis, preparation of test samples, etc., can solve the problems of insignificant color change at the end point of titration, difficult control in actual operation, perchloric acid fuming and distilling out, etc. , to achieve the effect of easy promotion and application, easy control and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the present invention, the present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but content of the present invention is not only limited to following embodiment:

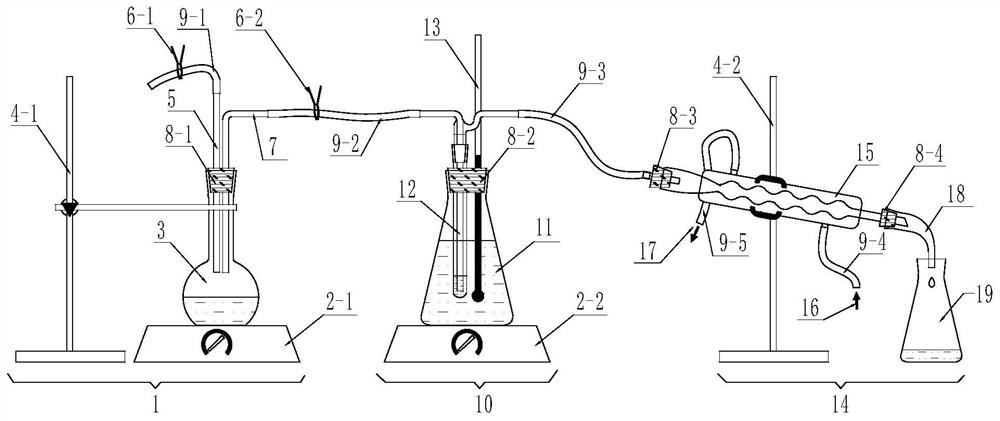

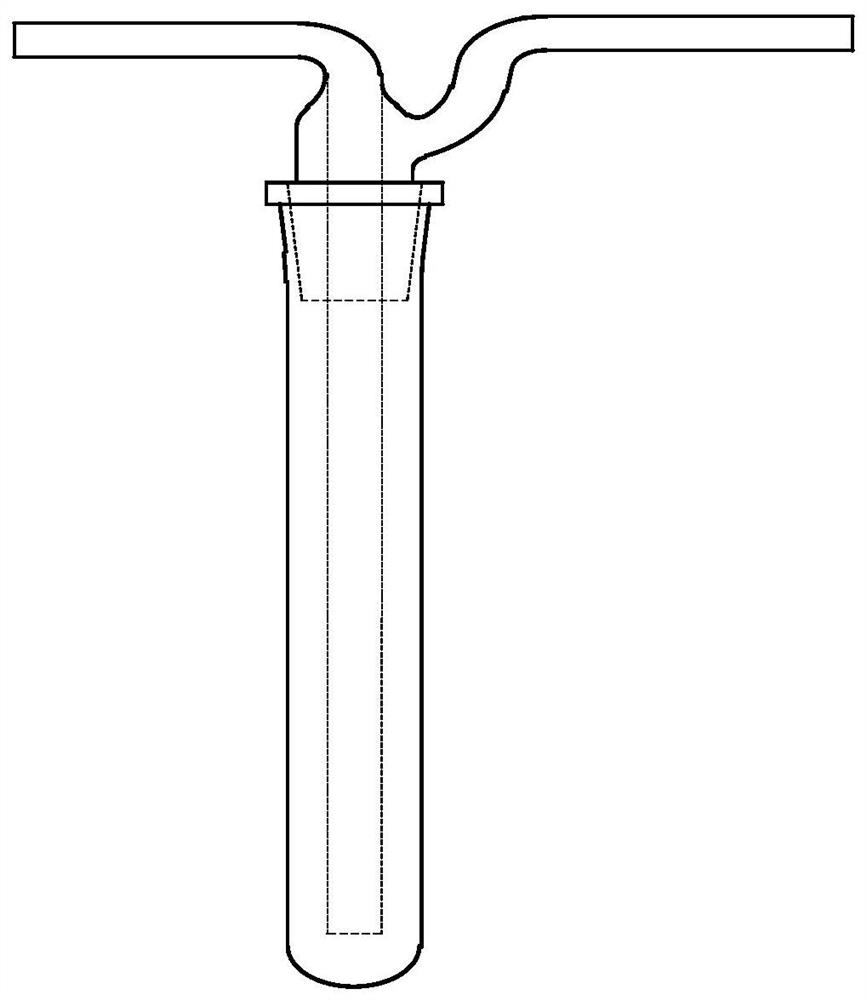

[0040] Such as figure 1 The device for measuring the fluorine content in a metallurgical slagging agent is shown, including a steam transmission part 1, a sample reaction part 10, and a condensation collection part 14. The steam transmission part 1 is used to generate steam, and the steam is used as a carrier gas and a solution The reactants generated by the reaction part 10 are dissolved and condensed by the condensation collection part 14 and enter the collection container 19, which includes a heating device 2, a distillation bottle 3, an iron stand 4, a safety tube 5, a water stop clamp 6-1, a water stop Clamp 6-2, air guiding elbow 7 and rubber stopper 8-1; the retort 3 is fixed by the iron stand 4, the bottom pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com