Burst-proof non-toxic protective layer for valve core of water faucet

A protective layer and faucet technology, applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve the problems of easy bursting, troublesome maintenance, water leakage of the valve core, etc., and achieve good sealing, short bonding time and good bonding degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

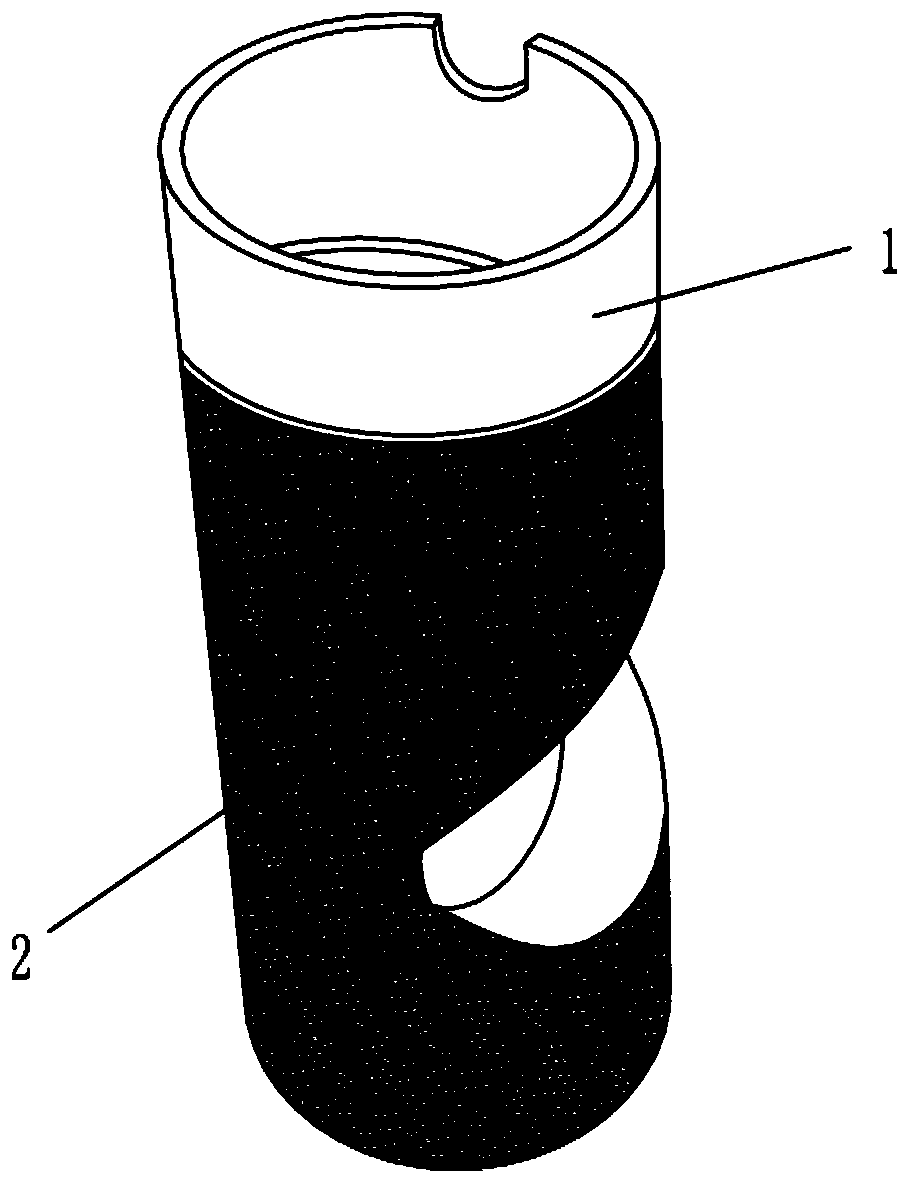

[0021] An explosion-proof and non-toxic protective layer for a faucet valve core, such as figure 1 As shown, it includes a faucet spool 1 and a protective layer 2, and the protective layer 2 is applied to the faucet spool 1; the protective layer 2 is composed of the following raw materials counted according to the total mass fraction of 100%: gypsum powder 10% , 10% talcum powder, 5% anti-blocking king, 25% glass glue, 0.5% reinforcing agent, 49.5% iron sand; the gypsum powder is processed by anhydrous gypsum grinding; the talcum powder is plastic grade talcum powder, The whiteness is 88%-95%, and the fineness is 45μm±45μm·2%. The anti-blocking king is composed of the following raw materials counted according to the total mass fraction of 100%: 76% of sulfoaluminate cement, 18% of quartz powder , Calcium Chloride 1.37%, Lithium Chloride 0.75%, Talc Powder 0.6%, Zinc Stearate 0.57%, Hydroxypropyl Methyl Cellulose 0.6%, Water Reducer 0.5%, Wollastonite Powder 0.45%, Titanium Dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com