High temperature resistant pearlescent pigment and preparation method thereof

A technology of pearlescent pigments and high temperature resistance, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of poor color fastness, long production cycle, complicated production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

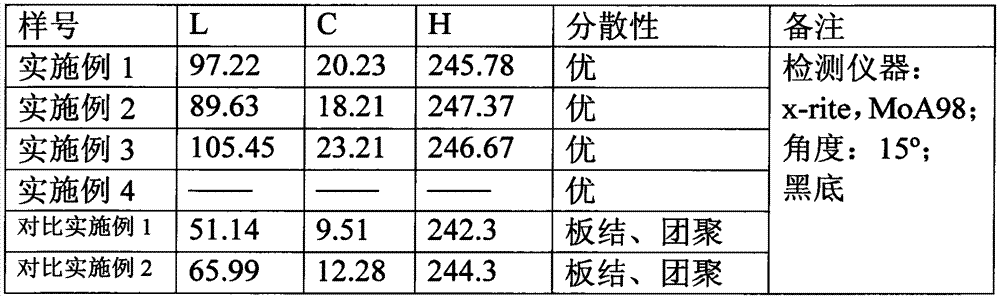

Examples

Embodiment 1

[0034] (1) Weigh 90 g of pearlescent grade synthetic mica powder with a particle size of 40 to 160 μm, add 720 ml of deionized water according to solid-liquid (1:8), and stir to form a suspension;

[0035] (2) Stir the suspension and heat it up to 62°C, adjust the pH value to 1.5 with dilute hydrochloric acid; under constant temperature stirring, slowly add 2% (wt) SnCl 4 ·5H 2 O solution 90ml, dropwise add 20%NaOH solution simultaneously to keep the pH value constant, and stir at constant temperature for 15 minutes after the dropwise addition;

[0036] (3) Stir and heat up to 75°C, adjust the pH value of the suspension to 1.8 with dilute liquid alkali, and slowly add 2mol / L TiCl dropwise 4 solution, while adding 20% NaOH solution dropwise to keep the pH value constant until the color reaches silvery white, and continue to stir at constant temperature for 15 minutes;

[0037] (4) Keep the temperature at 75°C, adjust the pH value to 3.4 with dilute liquid alkali, slowly add...

Embodiment 2

[0042] (1) Weigh 90g of pearlescent grade synthetic mica powder with a particle size of 40-160 μm, add 900ml of deionized water according to solid-liquid (1:10), and stir to form a suspension;

[0043] (2) Stir the suspension and heat it up to 66°C, adjust the pH value to 1.6 with dilute hydrochloric acid; under constant temperature stirring, slowly add 2.5% (wt) SnCl 4 ·5H 2 O solution 90ml, dropwise add 20%NaOH solution simultaneously to keep the pH value constant, and stir at constant temperature for 15 minutes after the dropwise addition;

[0044] (3) Stir and heat up to 80°C, adjust the pH value of the suspension to 2.0 with dilute liquid alkali, and slowly add 2mol / L TiCl dropwise 4 solution, while adding 20% NaOH solution dropwise to keep the pH value constant until the color reaches silvery white, and continue to stir at constant temperature for 15 minutes;

[0045] (4) Keep the temperature at 80°C, adjust the pH value to 3.8 with dilute liquid alkali, slowly add 1...

Embodiment 3

[0050] (1) Weigh 90g of pearlescent grade synthetic mica powder with a particle size of 40-160 μm, add 1080ml of deionized water according to solid-liquid (1:12), and stir to form a suspension;

[0051] (2) Stir the suspension and heat it up to 70°C, adjust the pH value to 1.8 with dilute hydrochloric acid; under constant temperature stirring, slowly add 3% (wt) SnCl 4 ·5H 2 O solution 90ml, dropwise add 20%NaOH solution simultaneously to keep the pH value constant, and stir at constant temperature for 15 minutes after the dropwise addition;

[0052] (3) Stir and heat up to 85°C, adjust the pH value of the suspension to 2.2 with dilute liquid alkali, and slowly add 2mol / L TiCl dropwise 4 solution, while adding 20% NaOH solution dropwise to keep the pH value constant until the color reaches silvery white, and continue to stir at constant temperature for 15 minutes;

[0053] (4) Keep the temperature at 85°C, adjust the pH value to 4.2 with dilute alkali, slowly add 150g (ZrO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com