Ni-Co-Al-Mg composite hydroxide, preparation method and application thereof

A composite hydroxide, nickel-cobalt-aluminum-magnesium technology, applied in nickel oxide/nickel hydroxide, electrochemical generators, electrical components, etc., can solve problems affecting the consistency of positive electrode materials and uneven distribution of doping elements. Achieve the effects of improved consistency, simple process, and reduced potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

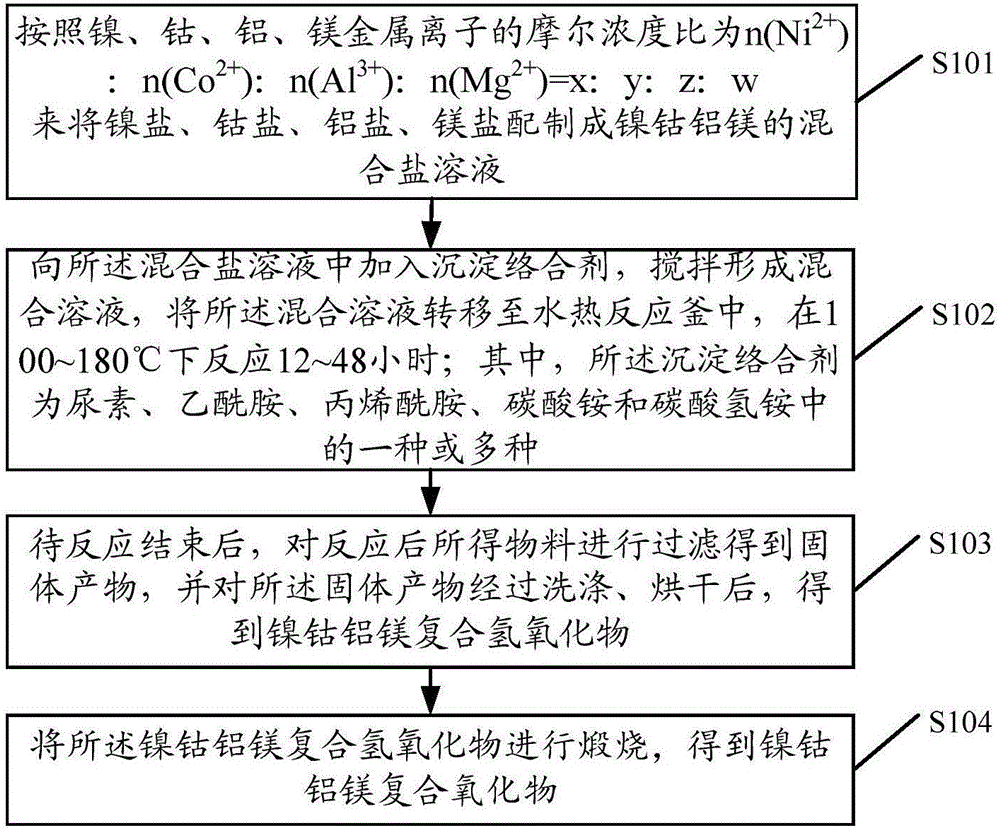

[0042] Please refer to figure 1 , figure 1 It is a flow chart of the preparation method of nickel-cobalt-aluminum-magnesium composite oxide in an implementation of the present invention, comprising the following steps:

[0043] S101, according to the molar concentration ratio of nickel, cobalt, aluminum, and magnesium metal ions, n(Ni 2+ ): n(Co 2+ ): n(Al 3+ ): n (Mg 2 + )=x: y: z: w nickel salt, cobalt salt, aluminum salt, magnesium salt are formulated into the mixed salt solution of nickel cobalt aluminum magnesium;

[0044] S102. Add a precipitation complexing agent to the mixed salt solution, stir to form a mixed solution, transfer the mixed solution to a hydrothermal reaction kettle, and react at 100-180°C for 12-48 hours; wherein, the precipitation The complexing agent is one or more of urea, acetamide, acrylamide, ammonium carbonate and ammonium bicarbonate;

[0045] S103. After the reaction is completed, filter the material obtained after the reaction to obtain...

Embodiment 1

[0049] A preparation method of nickel-cobalt-aluminum-magnesium composite oxide, comprising the following steps:

[0050] According to the molar concentration ratio of nickel, cobalt, aluminum, and magnesium metal ions, n(Ni 2+ ): n(Co 2+ ): n(Al 3+ ): n (Mg 2+ )=0.7:0.2:0.05:0.05, nickel salt, cobalt salt, aluminum salt, magnesium salt are formulated into a certain concentration of nickel-cobalt-aluminum-magnesium mixed salt solution, the total molar concentration of metal ions in the mixed salt solution is 1mol / L;

[0051] Prepare 40mL, 10mol / L urea solution, stir it with 40mL of the above-mentioned mixed salt solution to form a uniform mixed solution, transfer the mixed solution to a polytetrafluoroethylene reactor, and react at 120°C for 24 hours;

[0052] After the reaction is finished, take out the reaction kettle, and after it is cooled to room temperature, filter and wash the material obtained after the reaction, and wash until the pH of the filtrate is neutral; o...

Embodiment 2

[0060] A preparation method of nickel-cobalt-aluminum-magnesium composite oxide, comprising the following steps:

[0061] According to the molar concentration ratio of nickel, cobalt, aluminum, and magnesium metal ions, n(Ni 2+ ): n(Co 2+ ): n(Al 3+ ): n (Mg 2+ )=0.75:0.15:0.05:0.05, nickel salt, cobalt salt, aluminum salt, magnesium salt are formulated into a certain concentration of nickel-cobalt-aluminum-magnesium mixed salt solution, and the total molar concentration of metal ions in the mixed salt solution is 1.5mol / L;

[0062] Prepare 80mL, 15mol / L urea solution, stir it with 80mL of the above-mentioned mixed salt solution to form a uniform mixed solution, transfer the mixed solution to a polytetrafluoroethylene reactor, and react at 150°C for 36 hours;

[0063] After the reaction is finished, take out the reaction kettle, and after it is cooled to room temperature, filter and wash the material obtained after the reaction, and wash until the pH of the filtrate is ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com