Styrene-acrylonitrile- diene copolymer compound and formed product made of the compound

A technology of copolymer and acrylonitrile, which is applied in the field of styrene-acrylonitrile-diene copolymer composition, can solve the problems of disturbing biological endocrine function and achieve the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

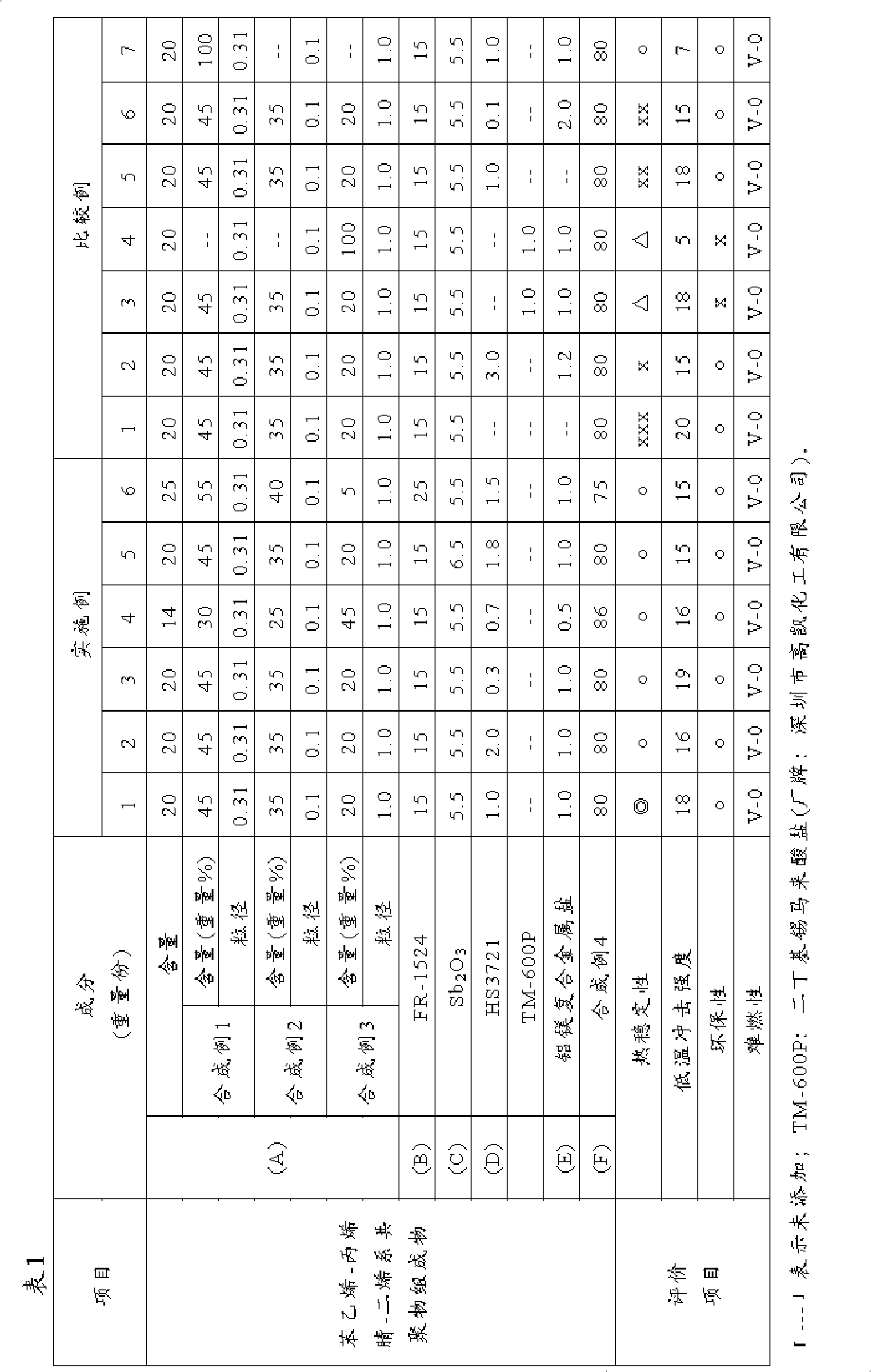

Examples

preparation example Construction

[0041] 1 ) preparation>

[0042] The first copolymer component (A 1 ) is prepared by emulsification polymerization which contains 40% to 90% by weight of the first rubber emulsion (solid content) and 10% to 60% by weight of the first monomer component. The first monomer component includes 50% to 85% by weight of styrene monomer (i-1), 15% to 50% by weight of acrylonitrile monomer (i-2), and 0% by weight -35% by weight of other copolymerizable vinylic monomers (i-3). In this emulsion polymerization reaction, an emulsifier, a polymerization initiator, a chain transfer agent, etc. can be optionally added. After the emulsification polymerization reaction, it can optionally go through the steps of coagulation, dehydration and drying.

[0043] The first rubber emulsion is obtained by emulsion polymerization of the first rubber component, and after the emulsion polymerization, it is further treated with agglomeration (Agglomeration), and selectively added to other copolymerizable ...

Synthetic example 1

[0091] [Synthesis Example 1] The first copolymer component (A 1 )

[0092] 95.0 parts by weight of 1,3-butadiene, 5.0 parts by weight of acrylonitrile, 15.0 parts by weight of potassium persulfate solution, 3.0 parts by weight of sodium pyrophosphate, 1.5 parts by weight of potassium oleate, 140.0 parts by weight of distilled water and 0.2 parts by weight of tertiary-dodecyl mercaptan were reacted at a reaction temperature of 65°C for 12 hours to obtain a rubber emulsion with a conversion rate of 94%, a solid content of about 40%, and a weight average particle size of 0.1 μm.

[0093] 85.0 parts by weight of ethyl acrylate, 15.0 parts by weight of acrylic acid, 0.3 parts by weight of tert-dodecyl mercaptan, 2.0 parts by weight of potassium oleate, 1.0 parts by weight of dioctyl sodium sulfosuccinate, 0.4 parts by weight Parts of cumene hydroperoxide, 0.3 parts by weight of sodium formaldehyde sulfoxylate and distilled water of 200.0 parts by weight were reacted for 5 hours at...

Synthetic example 2

[0096] [Synthesis Example 2] The second copolymer component (A 2 )

[0097] 95.0 parts by weight of 1,3-butadiene, 5.0 parts by weight of acrylonitrile, 15.0 parts by weight of potassium persulfate solution, 3.0 parts by weight of sodium pyrophosphate, 1.5 parts by weight of potassium oleate, 140.0 parts by weight of distilled water and 0.2 parts by weight of tertiary-dodecyl mercaptan were reacted at a reaction temperature of 65°C for 12 hours to obtain a rubber emulsion with a conversion rate of 94%, a solid content of about 40%, and a weight average particle size of 0.1 μm.

[0098] The above-mentioned rubber emulsion (dry weight) of 100.0 parts by weight, the styrene of 75.0 parts by weight, the acrylonitrile of 25.0 parts by weight, the potassium oleate of 2.0 parts by weight, the tert-dodecyl mercaptan of 0.6 parts by weight, 1.4 parts by weight Parts of cumene hydroperoxide, 8.6 parts by weight of ferrous sulfate solution (0.2% by weight of concentration), 8.6 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Weight average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com