Method for preparing in-situ self-generated TiB2 reinforced composite material based on SLM

A reinforced composite material, in-situ self-generated technology, applied in the direction of additive processing, can solve the problems of high thermal conductivity, poor fluidity of aluminum and its alloys, and reduce material plasticity, achieving huge application potential, microstructure refinement, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 2.5wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / Al7SiCu0.5Mg composite material;

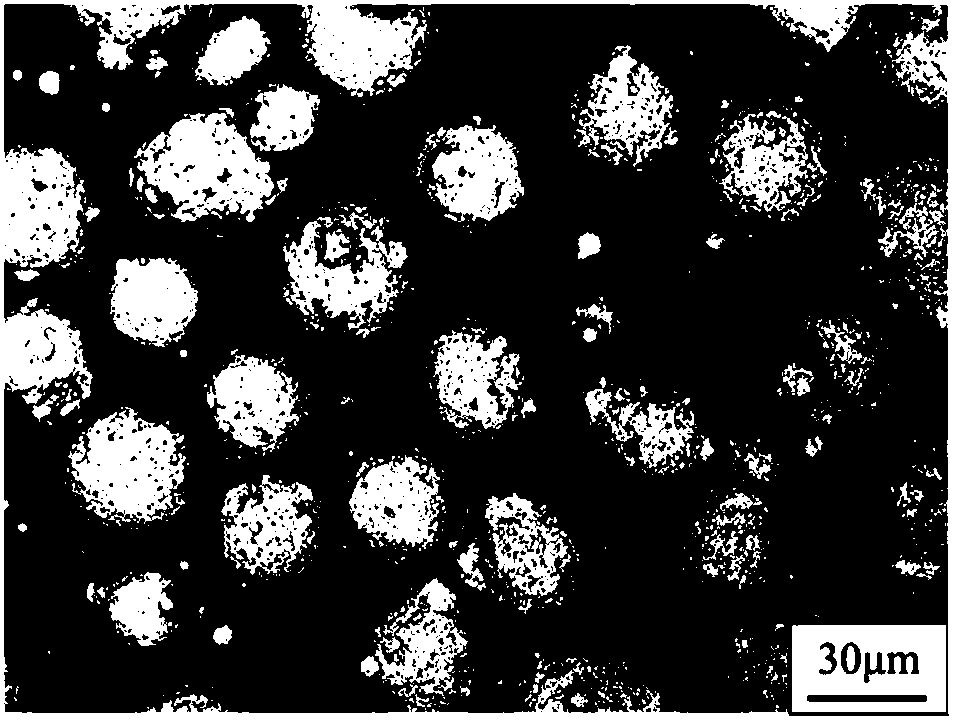

[0026] (2) The powder is prepared by vacuum air atomization technology, the melt temperature is 1000°C, the Ar gas is used for protection and gas atomization, the air pressure is 4.5MPa, and the nozzle diameter is 0.5mm; figure 1 shown;

[0027] (3) Use the software SolidWorks to draw the three-dimensional graphics of the required processing samples, the graphics are 10*10*10mm cubes and standard tensile sheets, and save them in STL format;

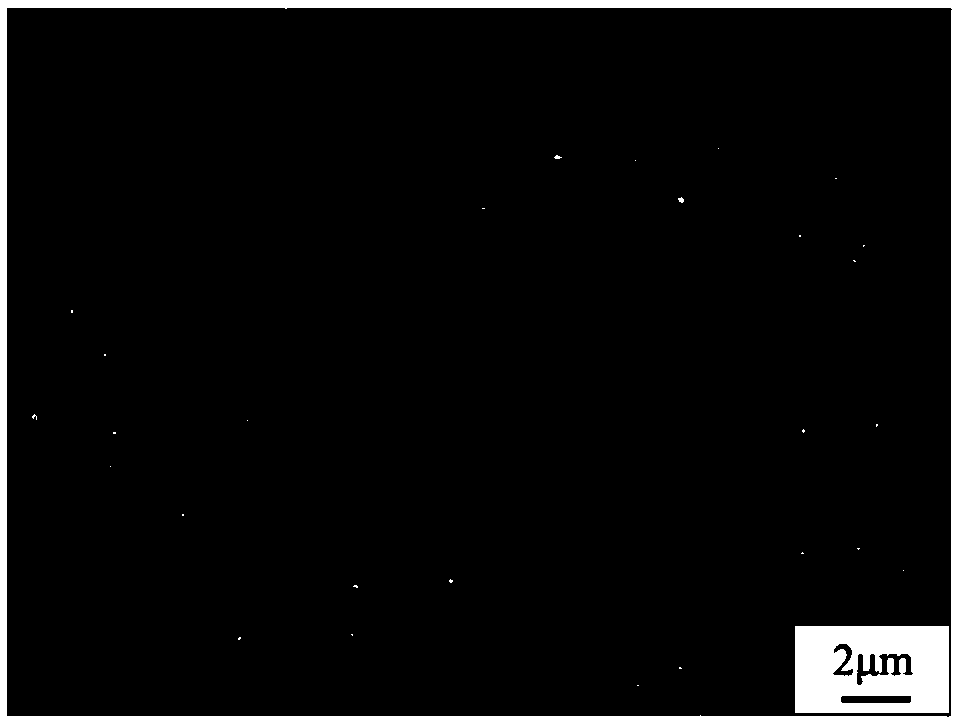

[0028] (4) The SLM sample is prepared using a metal 3D printer, such as figure 2 and image 3 As shown, the laser power is 370W, the scanning speed is 1300mm / s, the layer thickness is 30μm, and the scanning distance is 0.19mm. During the printing of the first five layers, a grid is added to spread the powder evenly on the substrate...

Embodiment 2

[0031] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 2.5wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / Al7SiCu0.5Mg composite material;

[0032] (2) The powder is prepared by vacuum air atomization technology, the melt temperature is 1200°C, the mixed gas of Ar and H2 is used for protection and gas atomization, the air pressure is 9.5MPa, and the diameter of the nozzle is 2mm; the particle size of the sieved powder is 30- 50μm powder;

[0033] (3) Use the software SolidWorks to draw the three-dimensional graphics of the required processing samples, the graphics are 10*10*10mm cubes and standard tensile sheets, and save them in STL format;

[0034] (4) SLM samples were prepared using a metal 3D printer, where the laser power was 370W, the scanning speed was 1300mm / s, the layer thickness was 30μm, and the scanning distance was 0.19mm. During the printing of the first five layers, a grid is added to spread the ...

Embodiment 3

[0037] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 2.5wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / Al7SiCu0.5Mg composite material;

[0038] (2) The powder is prepared by vacuum air atomization technology, the melt temperature is 1000°C, protected by He gas and atomized, the air pressure is 5.5MPa, and the diameter of the nozzle is 3mm; the powder with a particle size of 15-53μm is left after sieving;

[0039] (3) Draw the three-dimensional graphics of the required processing samples through the software SolidWorks, the graphics are 10*10*6mm cubes and standard tensile sheets, and save them in STL format;

[0040] (4) SLM samples were prepared using a metal 3D printer, where the laser power was 370W, the scanning speed was 1000mm / s, the layer thickness was 30μm, and the scanning distance was 0.19mm. During the printing of the first five layers, a grid is added to spread the powder evenly on the substrate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com