Preparation of in situ self-generated tib based on slm 2 Methods of Strengthening Composite Materials

A reinforced composite material, in-situ self-generated technology, applied in the direction of additive processing, etc., can solve problems such as easy oxidation, difficult forming process, and reduced material plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 2.5wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / Al7SiCu0.5Mg composite material;

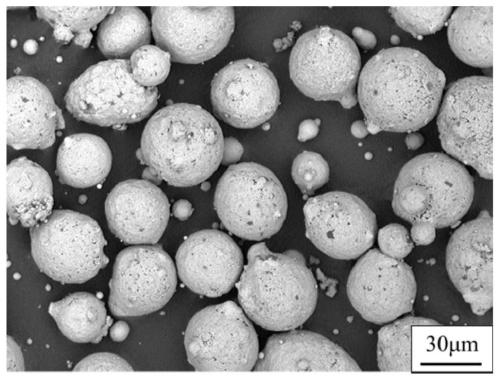

[0026] (2) The powder is prepared by vacuum air atomization technology, the melt temperature is 1000°C, the Ar gas is used for protection and gas atomization, the air pressure is 4.5MPa, and the nozzle diameter is 0.5mm; figure 1 shown;

[0027] (3) Use the software SolidWorks to draw the three-dimensional graphics of the required processing samples, the graphics are 10*10*10mm cubes and standard tensile sheets, and save them in STL format;

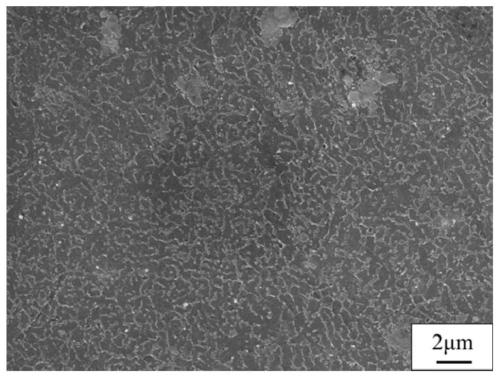

[0028] (4) The SLM sample is prepared using a metal 3D printer, such as figure 2 and image 3 As shown, the laser power is 370W, the scanning speed is 1300mm / s, the layer thickness is 30μm, and the scanning distance is 0.19mm. During the printing of the first five layers, a grid is added to spread the powder evenly on the substrate...

Embodiment 2

[0031] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 2.5wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / Al7SiCu0.5Mg composite material;

[0032] (2) The powder is prepared by vacuum air atomization technology, the melt temperature is 1200°C, the mixed gas of Ar and H2 is used for protection and gas atomization, the air pressure is 9.5MPa, and the diameter of the nozzle is 2mm; the particle size of the sieved powder is 30- 50μm powder;

[0033] (3) Use the software SolidWorks to draw the three-dimensional graphics of the required processing samples, the graphics are 10*10*10mm cubes and standard tensile sheets, and save them in STL format;

[0034] (4) SLM samples were prepared using a metal 3D printer, where the laser power was 370W, the scanning speed was 1300mm / s, the layer thickness was 30μm, and the scanning distance was 0.19mm. During the printing of the first five layers, a grid is added to spread the ...

Embodiment 3

[0037] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 2.5wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / Al7SiCu0.5Mg composite material;

[0038] (2) The powder is prepared by vacuum air atomization technology, the melt temperature is 1000°C, protected by He gas and atomized, the air pressure is 5.5MPa, and the diameter of the nozzle is 3mm; the powder with a particle size of 15-53μm is left after sieving;

[0039] (3) Draw the three-dimensional graphics of the required processing samples through the software SolidWorks, the graphics are 10*10*6mm cubes and standard tensile sheets, and save them in STL format;

[0040] (4) SLM samples were prepared using a metal 3D printer, where the laser power was 370W, the scanning speed was 1000mm / s, the layer thickness was 30μm, and the scanning distance was 0.19mm. During the printing of the first five layers, a grid is added to spread the powder evenly on the substrate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com