Method for preparing nano-Ce-Magnesium coumpoud oxide

A composite oxide, nanotechnology, applied in magnesium compounds, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high production cost, harsh reaction conditions, uneven dispersion, etc., to achieve no loss of raw materials, easy The effect of industrial production and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

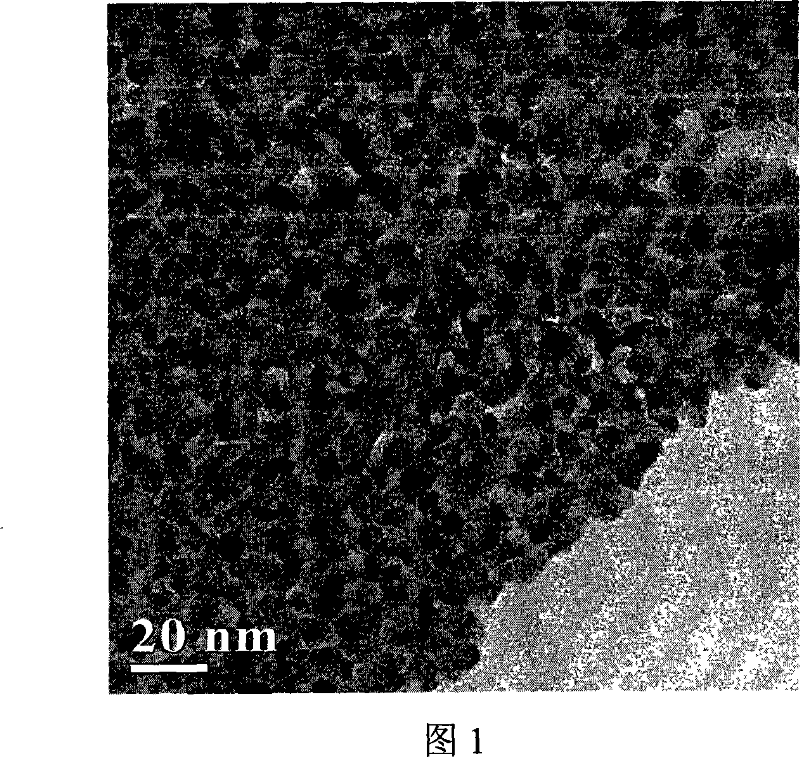

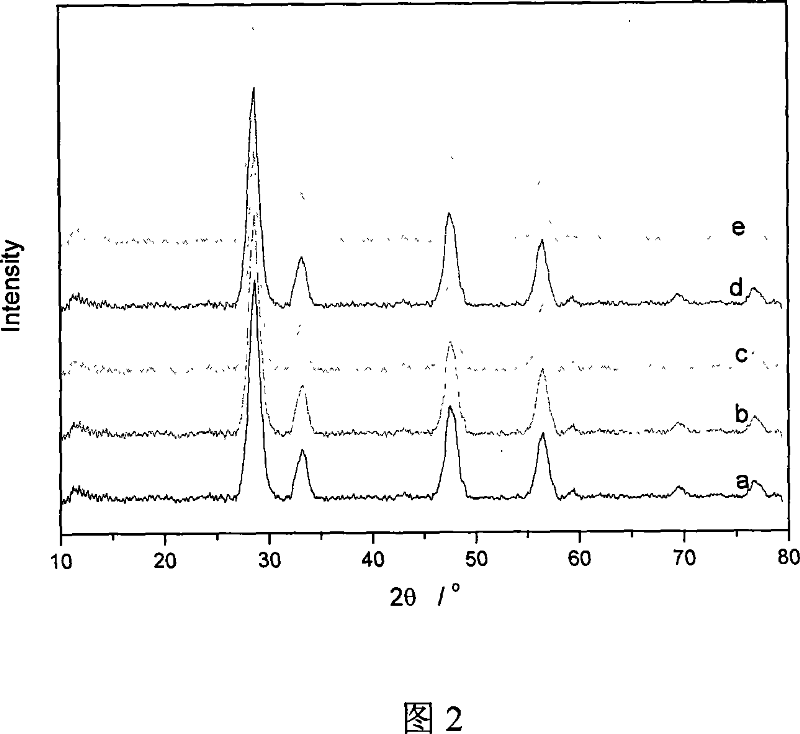

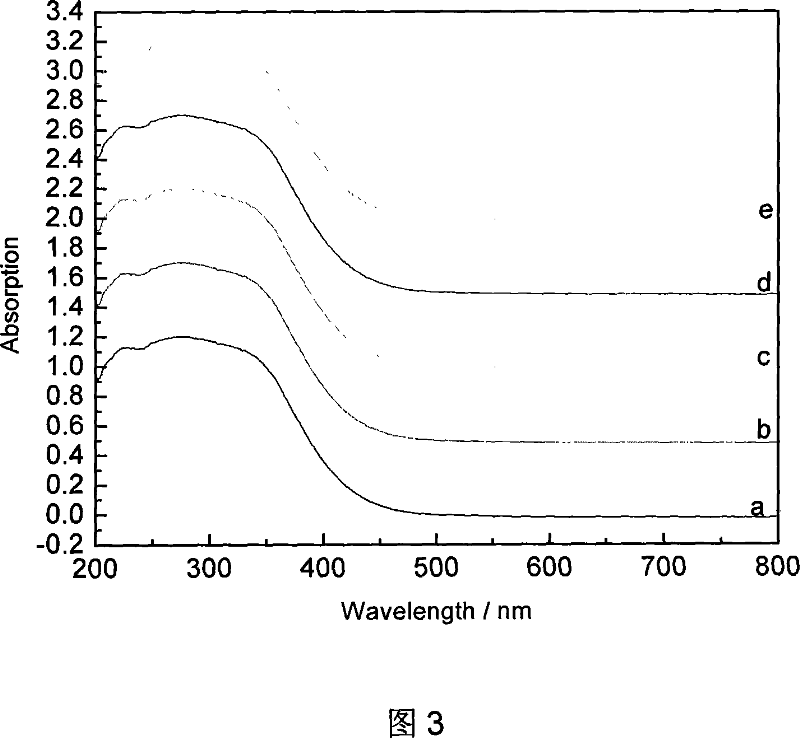

Embodiment 1

[0024] With cerium nitrate hexahydrate and basic magnesium carbonate pentahydrate as the source of cerium and magnesium, malic acid as complexing agent, get 0.4857g basic magnesium carbonate pentahydrate and 2.1713g cerium nitrate hexahydrate respectively dissolved in 15ml of water and mix, Then add malic acid 0.6707g, the molar ratio of cerium ion and magnesium ion is 1:1, the molar ratio of malic acid and total metal ion is 0.5:1, after dissolving, stir at room temperature for 2h, dropwise add ammonia water to adjust pH=5.00, Then keep the temperature at 50°C until a gel is formed, and then put it into a vacuum oven and dry at 60°C for 3 hours to obtain a fluffy and porous xerogel. It was placed in a muffle furnace at 500°C and calcined for 3 hours to obtain a light yellow powder product, nano-CeMgO3.

Embodiment 2

[0026] With cerium nitrate hexahydrate and basic magnesium carbonate pentahydrate as cerium source and magnesium source, malic acid as complexing agent, get 0.8747g basic magnesium carbonate pentahydrate and 0.4346g cerium nitrate hexahydrate respectively dissolved in 15ml of water and mix, Then add 1.3413g of malic acid, the molar ratio of cerium ion to magnesium ion is 1:9, and the molar ratio of malic acid to total metal ions is 1:1. After dissolving, stir at room temperature for 3h, add dropwise ammonia water to adjust pH=6.00, Then keep the temperature at 60°C until a gel is formed, and then put it into a vacuum oven and dry at 80°C for 5 hours to obtain a fluffy and porous xerogel. It was calcined in a muffle furnace at 600°C for 2 hours to obtain a light yellow powder product, nano-Ce0.1Mg0.9O1.1.

Embodiment 3

[0028] With cerium nitrate hexahydrate and basic magnesium carbonate pentahydrate as cerium source and magnesium source, malic acid as complexing agent, get 0.0972g basic magnesium carbonate pentahydrate and 3.9082g cerium nitrate hexahydrate respectively dissolved in 15ml of water and mix, Then add 2.6817g of malic acid, the molar ratio of cerium ion and magnesium ion is 9:1, the molar ratio of malic acid and total metal ion is 2:1, after dissolving, stir at room temperature for 4h, add dropwise ammonia water to adjust pH=7.00, Then keep the temperature at 70°C until a gel is formed, and then put it into a vacuum oven and dry at 100°C for 7 hours to obtain a fluffy and porous dry gel. It was placed in a muffle furnace at 500°C and calcined for 3 hours to obtain a light yellow powder product, nano-Ce0.9Mg0.1O1.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com