A kind of preparation method of degradable layered zn-mg composite material

A composite material, zn-mg technology, applied in metal material coating technology, surgery, medical science, etc., can solve the problems of slow degradation of zinc alloy, high elastic modulus, too fast corrosion of magnesium alloy, etc., and achieve low elastic modulus The effect of high volume, good biocompatibility, and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

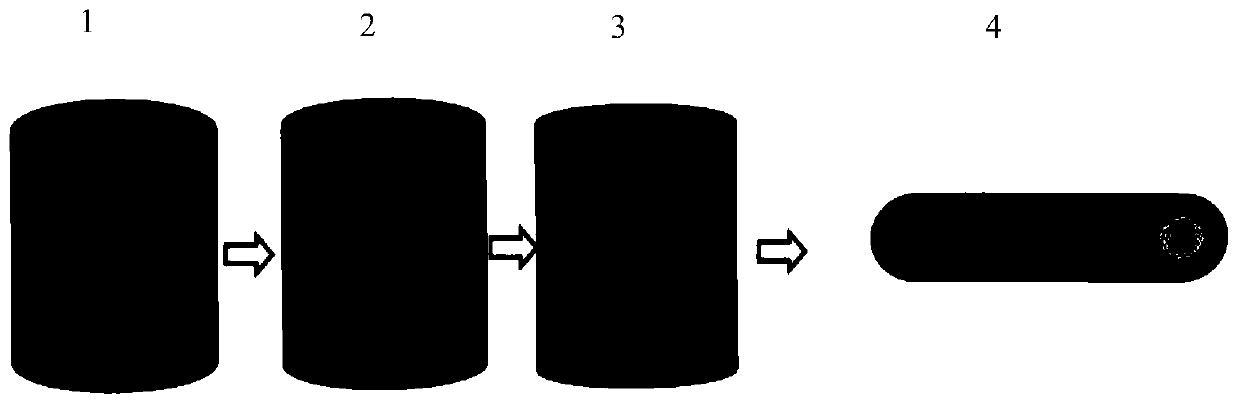

[0032] A degradable layered Zn-Mg composite material and its preparation method. The outer layer of the layered medical metal composite material is pure zinc, the core is pure magnesium, the total volume ratio of zinc is 50%, and the balance is pure magnesium . Extruded layered Zn-Mg composites were prepared by layered casting and nested extrusion, and then the circular cross-sections at both ends of the extruded layered Zn-Mg composites were fluorinated. The steps are as follows:

[0033] 1) at 10 -3Pass high-purity argon (99.99%) protective atmosphere under Pa vacuum condition, heat the base metal to 480°C to melt, stir with a stirring paddle for 5 minutes, let it stand for 3 minutes, and then cast it into a copper mold with a diameter of 60mm at 480°C In the casting mold, a cylindrical zinc ingot is obtained. The base metal is pure zinc, and the mass of pure zinc element is 3.3Kg.

[0034] 2) Pull out a barrel-shaped zinc ingot mold with an inner diameter of 42mm, a wal...

Embodiment 2

[0042] A kind of degradable layered Zn-Mg composite material and preparation method thereof, the outer layer of the layered medical metal composite material is pure zinc, the core is Mg-3(wt%)Zn-0.2(wt%)Ca alloy, zinc The total volume ratio is 30.5%, and the balance is magnesium alloy. The extruded degradable layered Zn-Mg composites were prepared by layered casting and nested extrusion, and then the circular cross-sections at both ends of the layered Zn-Mg composites were fluorinated. The steps are as follows:

[0043] 4) at 10 -3 Pass high-purity argon (99.99%) protective atmosphere under Pa vacuum condition, heat the base metal to 480°C to melt, stir with a stirring paddle for 5 minutes, let it stand for 3 minutes, and then cast it into a copper mold with a diameter of 60mm at 480°C In the casting mold, a cylindrical zinc ingot is obtained. The base metal is pure zinc, and the mass of pure zinc element is 3.3Kg.

[0044] 5) Take out a barrel-shaped zinc ingot casting mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com