Composite magnetic nanoparticles Fe3O4/MPS/PAA/NTA-Ni<2+> and preparation method and application thereof in separation and purification of histidine-tagged proteins

A nanoparticle and composite magnetic technology, applied in the field of nanomagnetic materials and biological analysis, can solve the problems of difficult and fast adsorption and movement, low magnetic response of magnetic microspheres, cumbersome synthesis process, etc., to ensure efficient enrichment and purification Efficiency, the ability to efficiently chelate metal ions, and the effect of simple separation and purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

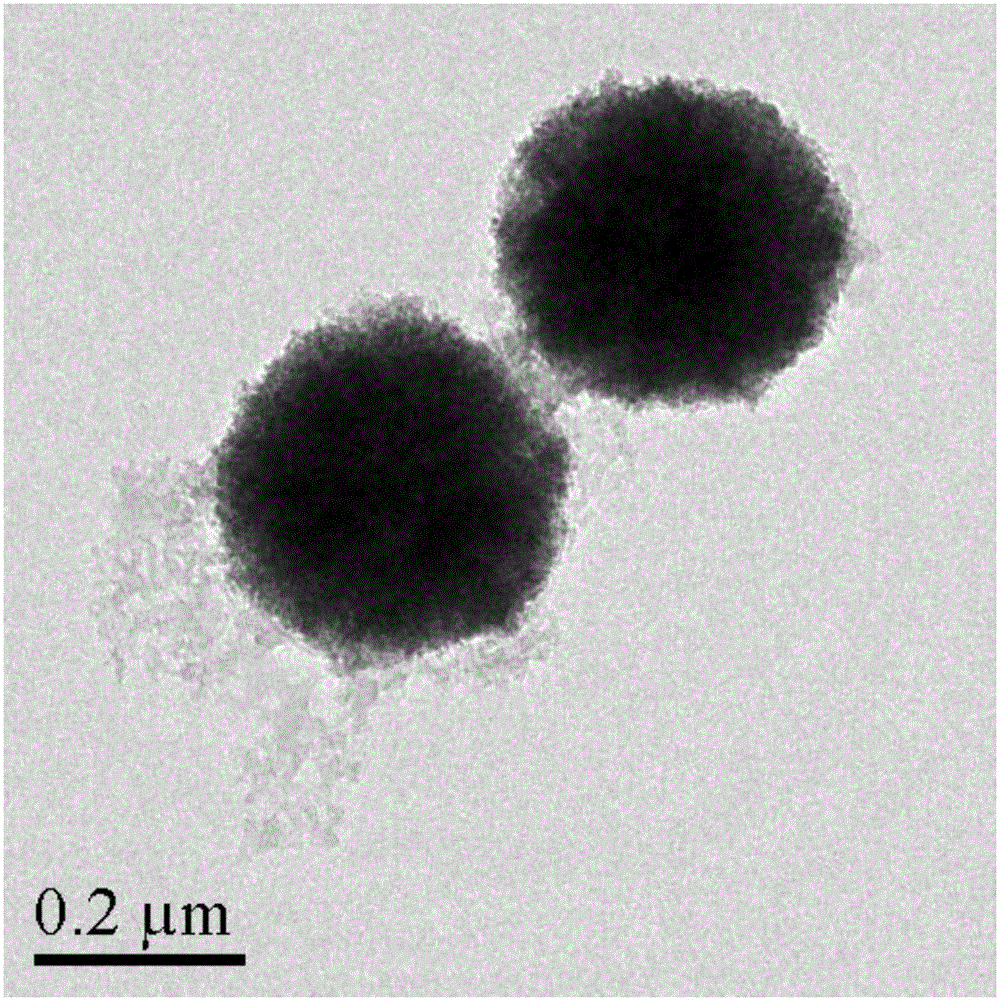

[0040] A kind of composite magnetic nanoparticle Fe of the present embodiment 3 o 4 / MPS / PAA / NTA-Ni 2+ The average hydrated particle size is 247.9nm.

[0041] The above-mentioned composite magnetic nanoparticles Fe 3 o 4 / MPS / PAA / NTA-Ni 2+ Prepared by the following method, comprising the steps of:

[0042] Step 1: Preparation of magnetic Fe by solvothermal method 3 o 4 Nanoparticles, the specific steps are as follows: Weigh 0.2889g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 0.8248g ammonium acetate (NH 4 AC) and 0.0856g sodium citrate in a round bottom flask, add 15ml ethylene glycol, dissolve, stir vigorously at 170°C for 1h, transfer to a polytetrafluoroethylene reactor after cooling, heat from room temperature to 200°C, and react 8h, then cooled to room temperature, and centrifuged to obtain 0.2g magnetic core Fe 3 o 4 Nanoparticles, the prepared product is washed with absolute ethanol for 3 to 4 times, and finally dispersed in absolute ethanol;

[0043] The...

Embodiment 2

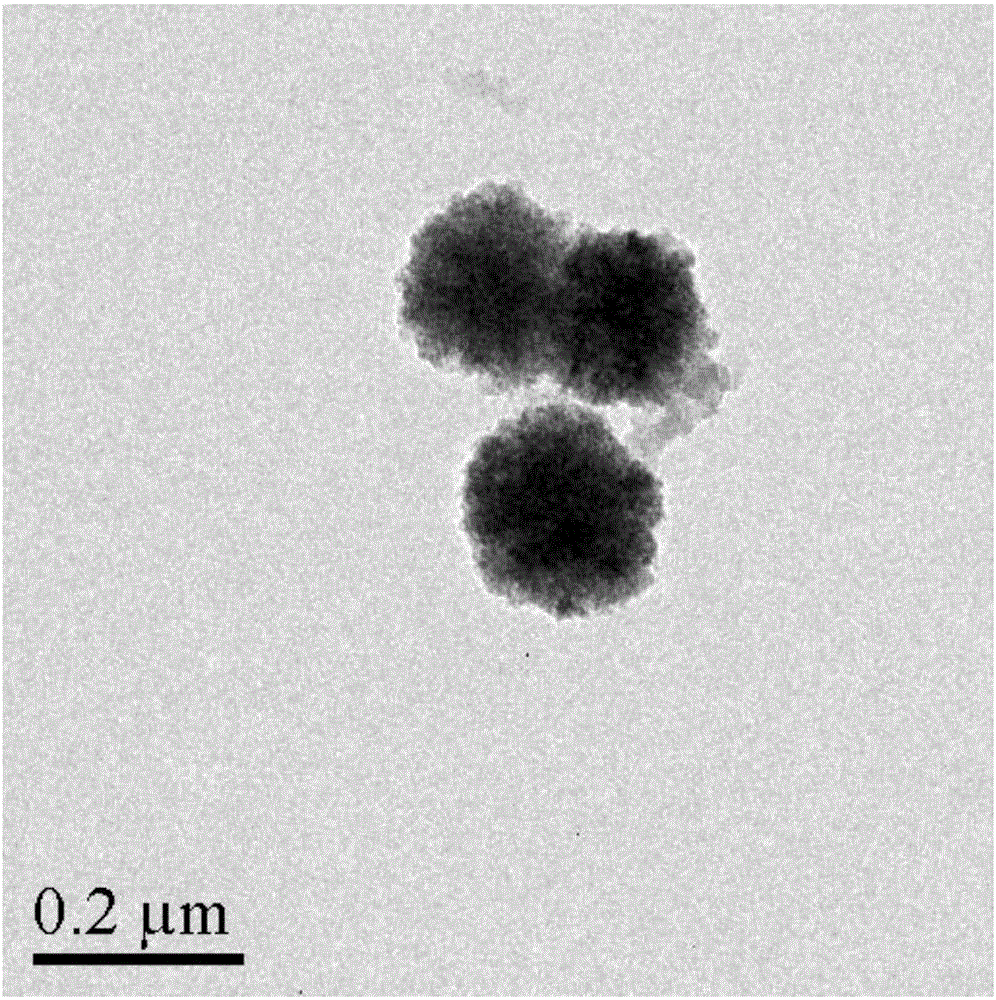

[0050] A kind of composite magnetic nanoparticle Fe of the present embodiment 3 o 4 / MPS / PAA / NTA-Ni 2+ The average hydrated particle size is 338nm.

[0051] The above-mentioned composite magnetic nanoparticles Fe 3 o 4 / MPS / PAA / NTA-Ni 2+ Prepared by the following method, comprising the steps of:

[0052] Step 1: Preparation of magnetic Fe by solvothermal method 3 o 4 Nanoparticles, the specific steps are as follows: Weigh 0.2889g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 0.8248g ammonium acetate (NH 4 AC) and 0.0856g sodium citrate in a round bottom flask, add 15ml ethylene glycol, dissolve, stir vigorously at 170°C for 1h, transfer to a polytetrafluoroethylene reactor after cooling, heat from room temperature to 200°C, and react 10h, then cooled to room temperature, and centrifuged to obtain 0.2g magnetic core Fe 3 o 4 Nanoparticles, the prepared product is washed with absolute ethanol for 3 to 4 times, and finally dispersed in absolute ethanol;

[0053] The ...

Embodiment 3

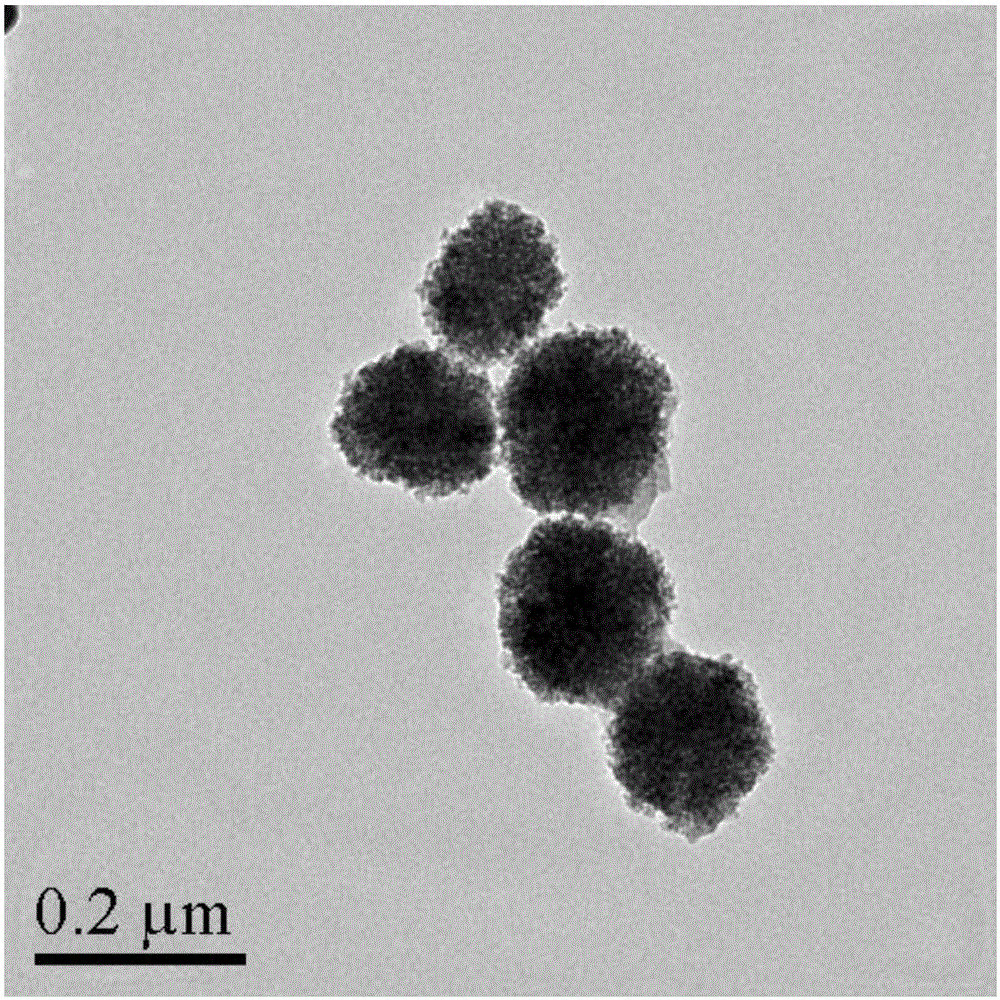

[0060] A kind of composite magnetic nanoparticle Fe of the present embodiment 3 o 4 / MPS / PAA / NTA-Ni 2+ The average hydrated particle size is 328.5nm.

[0061] The above-mentioned composite magnetic nanoparticles Fe 3 o 4 / MPS / PAA / NTA-Ni 2+ Prepared by the following method, comprising the steps of:

[0062] Step 1: Preparation of magnetic Fe by solvothermal method 3 o 4 Nanoparticles, the specific steps are as follows: Weigh 0.2889g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 0.8248g ammonium acetate (NH 4 AC) and 0.0856g sodium citrate in a round bottom flask, add 15ml ethylene glycol, dissolve, stir vigorously at 170°C for 1h, transfer to a polytetrafluoroethylene reactor after cooling, heat from room temperature to 200°C, and react 12h, then cooled to room temperature, and centrifuged to obtain 0.2g magnetic core Fe 3 o 4 Nanoparticles, the prepared product is washed with absolute ethanol for 3 to 4 times, and finally dispersed in absolute ethanol;

[0063] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hydrated particle size | aaaaa | aaaaa |

| Average hydrated particle size | aaaaa | aaaaa |

| Average hydrated particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com