Preparation method for preparing aluminum-based composite material based on laser selective melting

A technology of laser selective melting and aluminum-based composite materials, which is applied in the field of metallurgy and metal technology, can solve the problems of material stress concentration and cracking, and achieve the effects of reducing thermal stress, broad application prospects, and particle distribution and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a method for preparing an aluminum-based composite material based on laser selective melting, which includes the following steps:

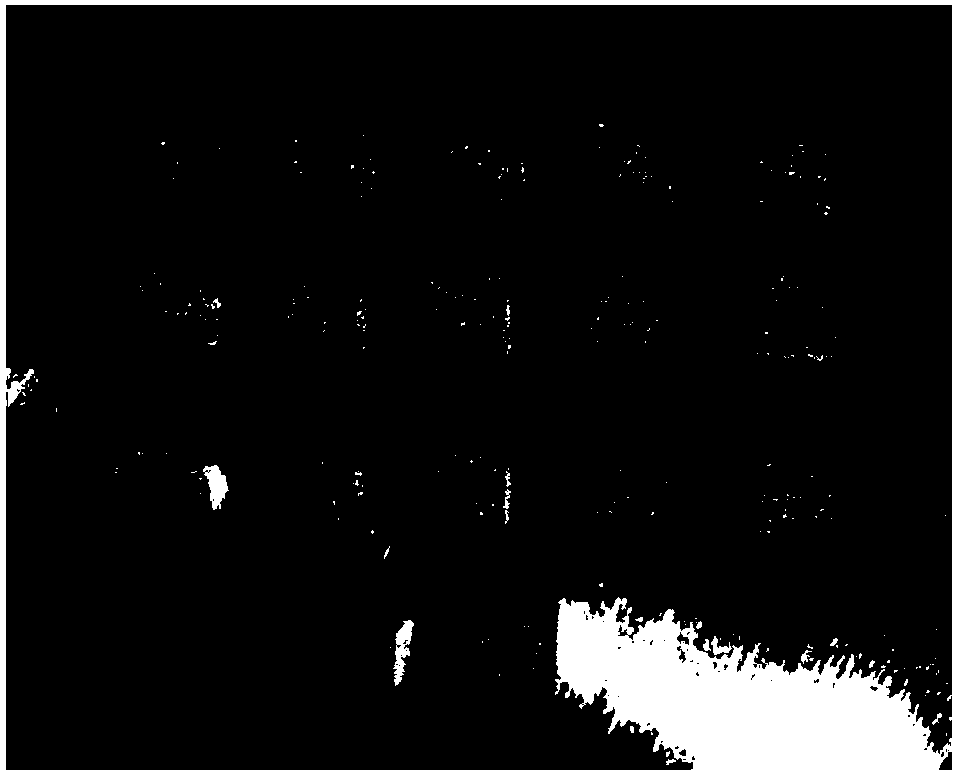

[0029] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 6wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / AlSi10Mg composite material, and the composite material powder is prepared by vacuum atomization technology, and the powder with a particle size of 15-53 μm is left after sieving, such as figure 1 shown;

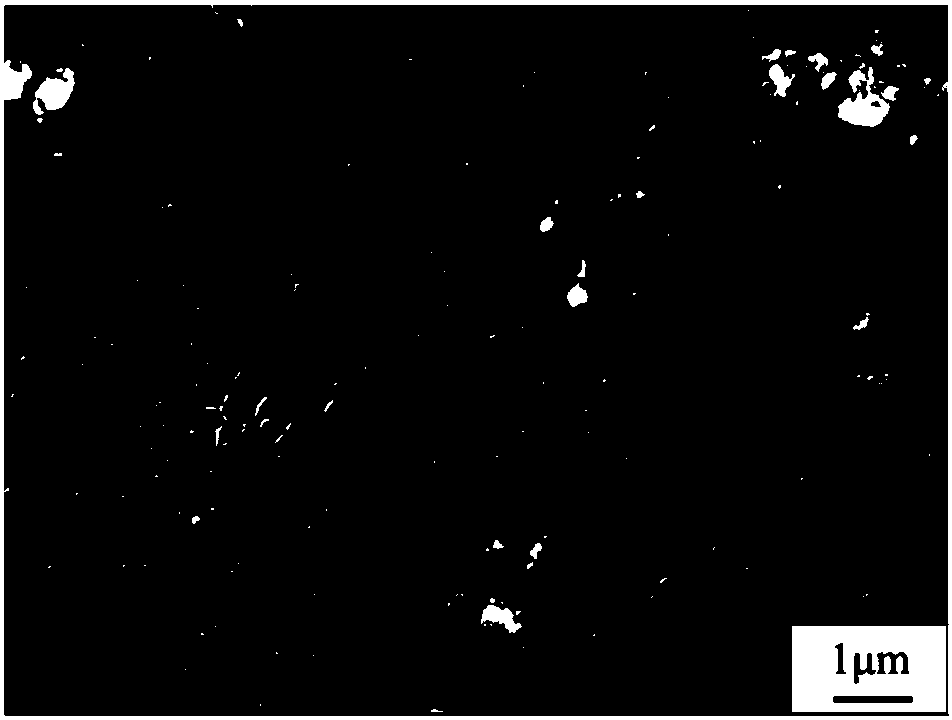

[0030] (2) The composite material powder is prepared by selective laser melting to obtain an SLM sample, such as figure 2 As shown, the microstructure of the image 3 As shown, the laser power used is 300W, the scanning speed is 1000mm / s, and the layer thickness is 30μm; the first to fifth layers are printed by manual scanning for 2 to 3 times to enhance the bonding force between cladding layers;

[0031] (3) Single-aging treatment is perform...

Embodiment 2

[0034] This embodiment relates to a method for preparing an aluminum-based composite material based on laser selective melting, which includes the following steps:

[0035] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 6wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / AlSi10Mg composite material, and the composite material powder is prepared by vacuum atomization technology, and the powder with a particle size of 15-53 μm is left after sieving;

[0036] (2) The composite material powder is prepared by selective laser melting to obtain SLM samples, the laser power used is 300W, the scanning speed is 1000mm / s, and the layer thickness is 30μm; the first to fifth layers are printed by manual scanning for 2 to 3 times way to enhance the bonding force between cladding layers;

[0037] (3) Single-aging treatment is performed on the SLM sample, and the aging temperature used is 150° C. for 6 hours.

[0038] In this ex...

Embodiment 3

[0040] This embodiment relates to a method for preparing an aluminum-based composite material based on laser selective melting, which includes the following steps:

[0041] (1) in KBF 4 、K 2 TiF 6 The powder is used as the raw material, and the in-situ self-generated 6wt% TiB is prepared by the mixed salt reaction method (LSM) 2 / AlSi10Mg composite material, and the composite material powder is prepared by vacuum atomization technology, and the powder with a particle size of 15-53 μm is left after sieving;

[0042] (2) The composite material powder is prepared by selective laser melting to obtain SLM samples, the laser power used is 300W, the scanning speed is 1000mm / s, and the layer thickness is 30μm; the first to fifth layers are printed by manual scanning for 2 to 3 times way to enhance the bonding force between cladding layers;

[0043] (3) Perform single aging treatment on the SLM sample, the aging temperature used is 150°C, and the time is 24h.

[0044] In this exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com