In-situ synthesized spinel whisker reinforced aluminum-based composite foam and preparation method thereof

A composite foam and in-situ synthesis technology, which is applied in the fields of refractory materials, energy absorption, and sound absorption, can solve the problems of uneven distribution of ceramic phases, poor contact between the matrix interface, etc., and achieve adjustable porosity, controllable process, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

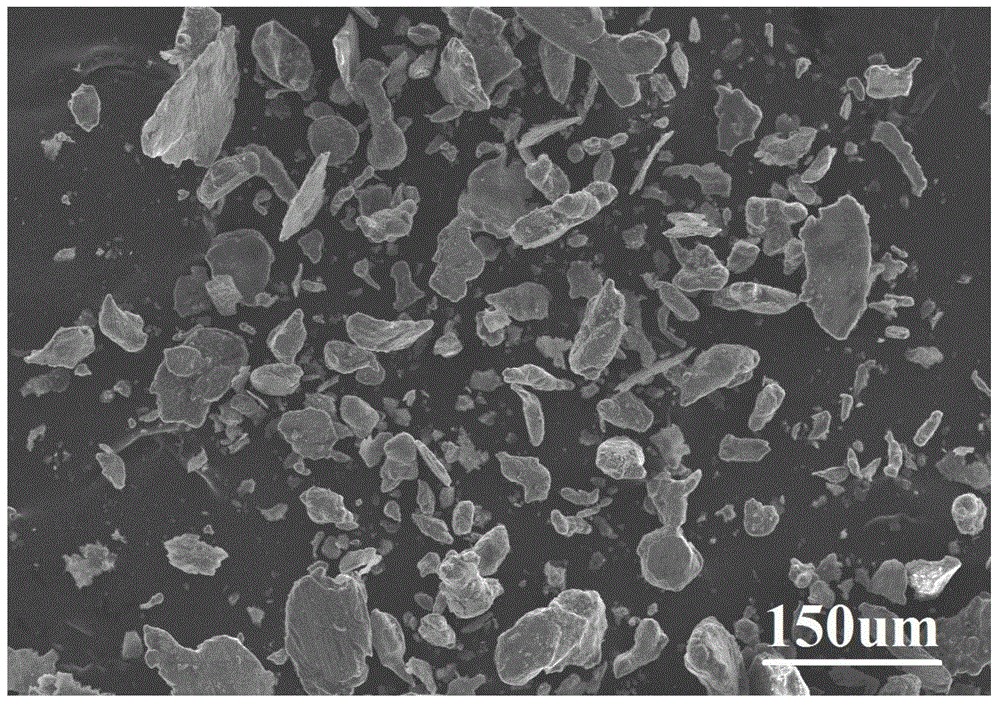

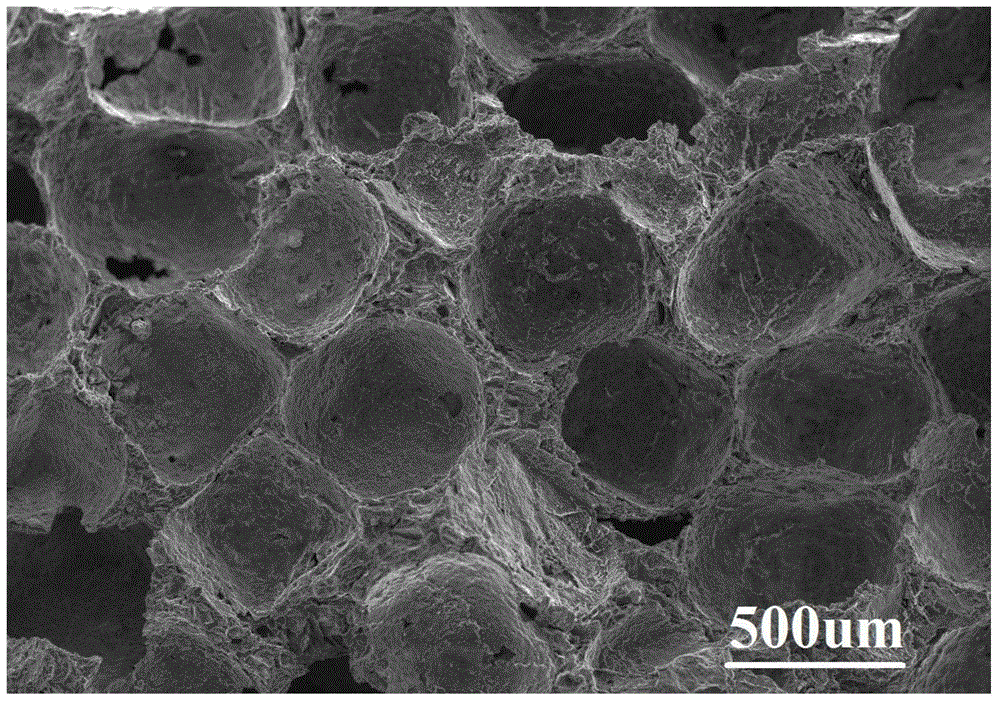

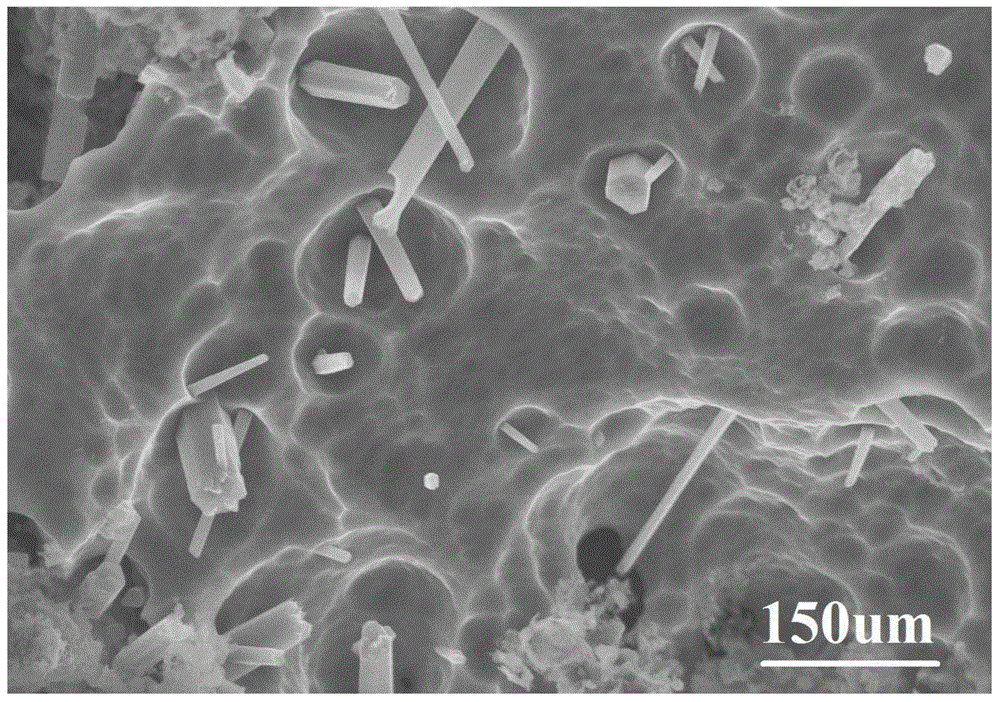

[0028] Get 11.6g of Al powder, 1.56g of Mg powder, 2.4g of boric acid and 0.1g of stearic acid for 11 hours with mechanical ball milling at a speed of 600 rpm, get 6.36g of powder after ball milling, and add 1.5ml of 4% PVA in mass fraction, after grinding Air dry for 1 hour. After mixing the ground powder with 8.18g NaCl evenly, press it into a bulk material at room temperature under a pressure of 300MPa. Then, the temperature was raised to 600° C. at a rate of 10° C. / min in an Ar atmosphere, and kept for 1 hour. After cooling to room temperature with the furnace, the sintered block was placed in a water bath at 80° C. for 24 hours to obtain an aluminum-based composite foam with a porosity of 60%.

Embodiment 2

[0030] Get 11.6g of Al powder, 1.56g of Mg powder, 2.4g of boric acid and 0.1g of stearic acid for 11 hours with mechanical ball milling at a speed of 750 rpm, get 6.36g of powder after ball milling, and add 1.5ml of 4% PVA in mass fraction, after grinding Air dry for 1 hour. After mixing the ground powder with 8.18g NaCl evenly, press it into a bulk material at room temperature under a pressure of 300MPa. Then, the temperature was raised to 600° C. at a rate of 10° C. / min in an Ar atmosphere, and kept for 1 hour. After cooling to room temperature with the furnace, the sintered block was placed in a water bath at 80° C. for 24 hours to obtain an aluminum-based composite foam with a porosity of 60%.

Embodiment 3

[0032] Get 11.6g of Al powder, 1.56g of Mg powder, 2.4g of boric acid and 0.1g of stearic acid for 10 hours with mechanical ball milling at a speed of 750 rpm, get 6.36g of powder after ball milling, and add 1.5ml of 4% PVA in mass fraction, after grinding Air dry for 1 hour. After mixing the ground powder with 8.18g NaCl evenly, press it into a bulk material at room temperature under a pressure of 300MPa. Then, the temperature was raised to 600° C. at a rate of 10° C. / min in an Ar atmosphere, and kept for 1 hour. After cooling to room temperature with the furnace, the sintered block was placed in a water bath at 80° C. for 24 hours to obtain an aluminum-based composite foam with a porosity of 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com