Al/Cu/Mg composite sheet rolling preparation method

A composite plate and aluminum alloy technology, applied in the direction of rolling force/roll gap control, metal rolling, metal rolling, etc., to achieve the effects of improving interface bonding strength, enhancing corrosion resistance, and increasing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

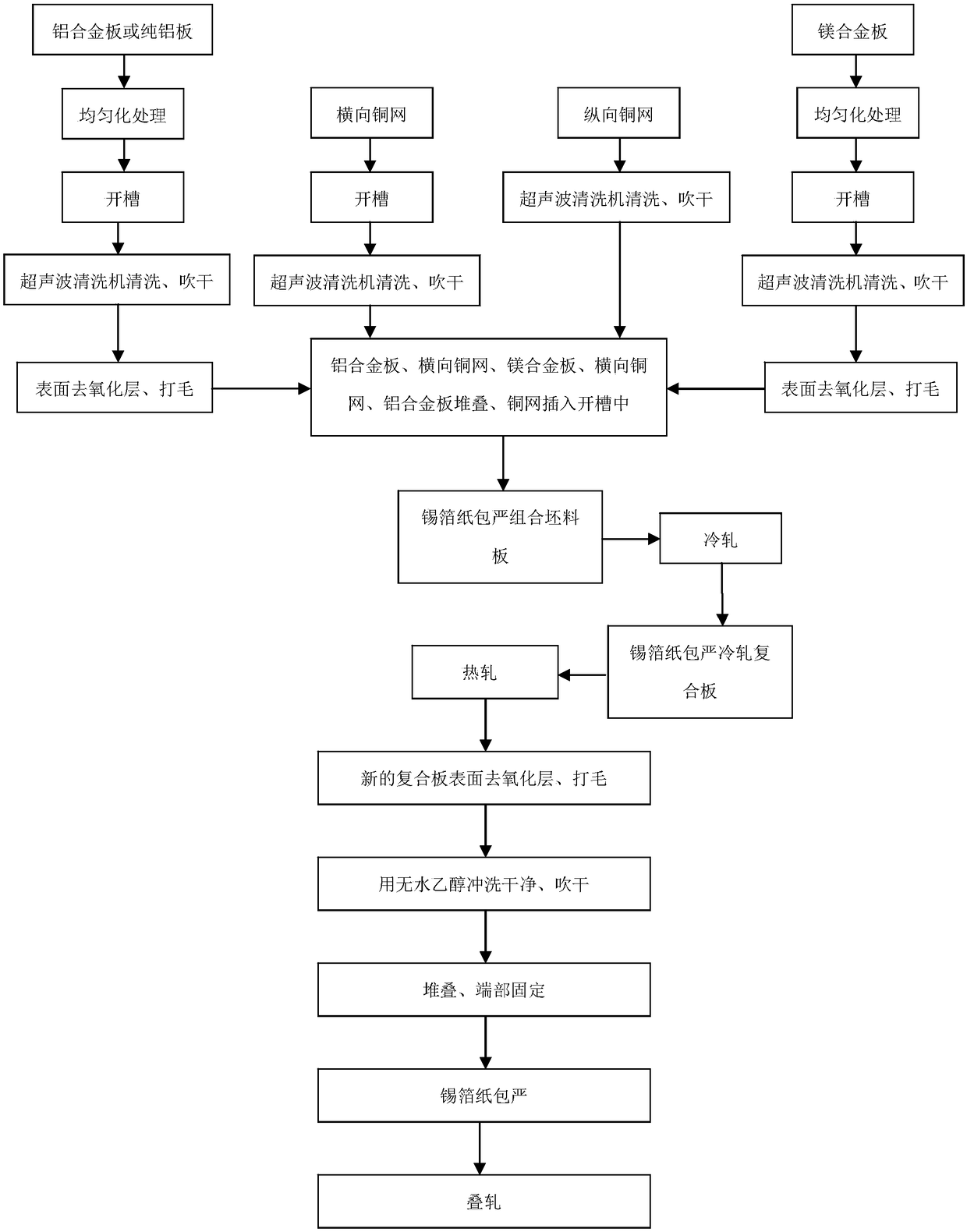

[0027] A method for preparing Al / Cu / Mg composite plate by rolling, comprising the steps of:

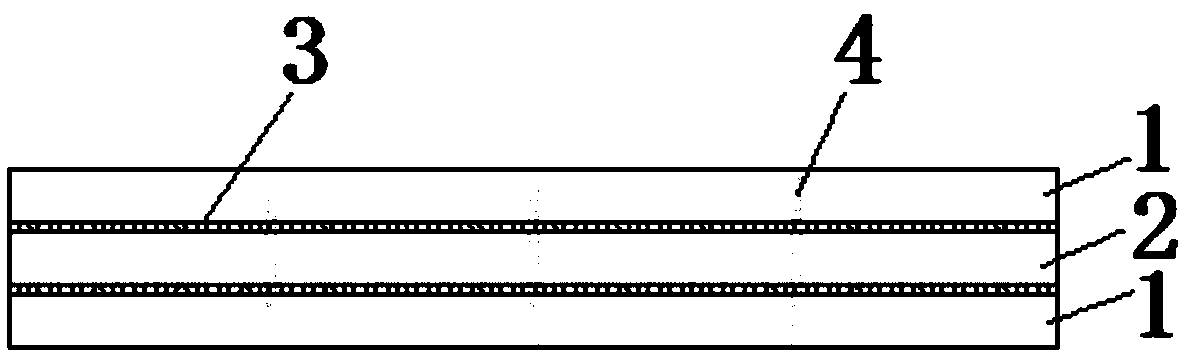

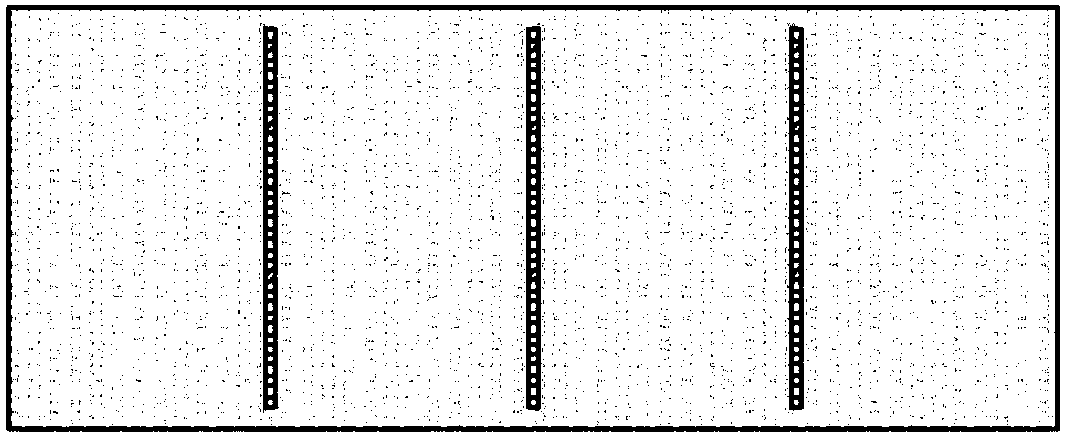

[0028] (1) Select pure aluminum billet (made of one of the AA1060 series aluminum plates) 1. Magnesium alloy billet (made of one of the AZ80 series magnesium alloy plates) 2. The size specification is 60mm×20mm×2mm, and the transverse copper The size specification of the mesh (copper mesh) 3 is 60mm×20mm, the size specification of the longitudinal copper mesh (copper mesh) 4 is 20mm×6.4mm, the wire diameter is 0.2mm, the structural shape of the hole is square, and the side length of the hole is 3mm.

[0029] (2) Homogenization heat treatment: Put the pure aluminum billet 1 into a heat treatment furnace, homogenize it at 475°C for 18 hours, then take it out and put it into pure water at 25°C for water cooling to room temperature; put the magnesium alloy billet 2 into heat treatment Homogenize in a furnace at 400°C for 15 hours, then take it out and put it into pure water at 25°C for wa...

Embodiment 2

[0038] A method for preparing Al / Cu / Mg composite plate by rolling, comprising the steps of:

[0039](1) Select aluminum alloy billet (made of one of the AA6061 series aluminum alloy plates) 1. Magnesium alloy billet (made of one of the AZ61 series of magnesium alloy plates) 2. The size is 60mm×20mm×1mm, The size specification of the horizontal copper mesh 3 (copper mesh) is 60mm×20mm, the size specification of the vertical copper mesh 4 (copper mesh) is 50mm×3.1mm, and the diameter of the wire is 0.05mm. The structural shape of the hole is a regular pentagon. The side length is 0.5mm.

[0040] (2) Homogenization heat treatment: put aluminum alloy billet 1 into a heat treatment furnace, homogenize it at 465°C for 24 hours, then take it out and put it into pure water at 25°C for water cooling to room temperature; put magnesium alloy billet 2 into heat treatment Homogenize in a furnace at 350°C for 18 hours, then take it out and put it into pure water at 25°C for water cooling t...

Embodiment 3

[0049] A method for preparing Al / Cu / Mg composite plate by rolling, comprising the steps of:

[0050] (1) Select aluminum alloy billet (made of one of AA5052 series aluminum alloy plates) 1. Magnesium alloy billet (made of one of AZ31 series magnesium alloy plates) 2 The size is 60mm×20mm×4mm, The size specification of the horizontal copper mesh (copper mesh) 3 is 60mm×20mm, the size specification of the vertical copper mesh (copper mesh) 4 is 15mm×13mm, the diameter of the wire is 0.5mm, the structure of the hole is circular, and the diameter of the hole circle is 6mm.

[0051] (2) Homogenization heat treatment: put aluminum alloy billet 1 into a heat treatment furnace, homogenize it at 485°C for 12 hours, then take it out and put it into pure water at 25°C for water cooling to room temperature; put magnesium alloy billet 2 into heat treatment Homogenize in a furnace at 450°C for 12 hours, then take it out and put it into pure water at 25°C for water cooling to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com