Preparation method for shell-nacreous-layer-imitating magnesium-based composite material

A composite material and nacre technology, which is applied in the field of biomimetic composite material preparation, can solve the problems of low production efficiency of directional freezing and thawing ice templates, inability to control the shape and size of reinforced particles, etc., and achieves good toughness, good wear resistance, high The effect of specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

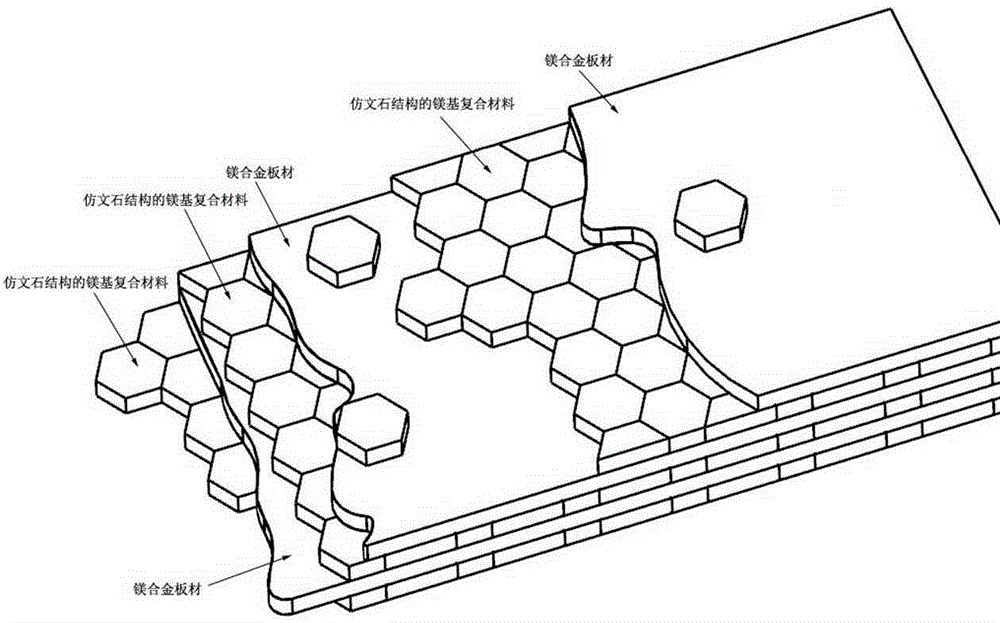

[0023] A preparation method of a magnesium-based composite material imitating shell nacre, comprising the following steps:

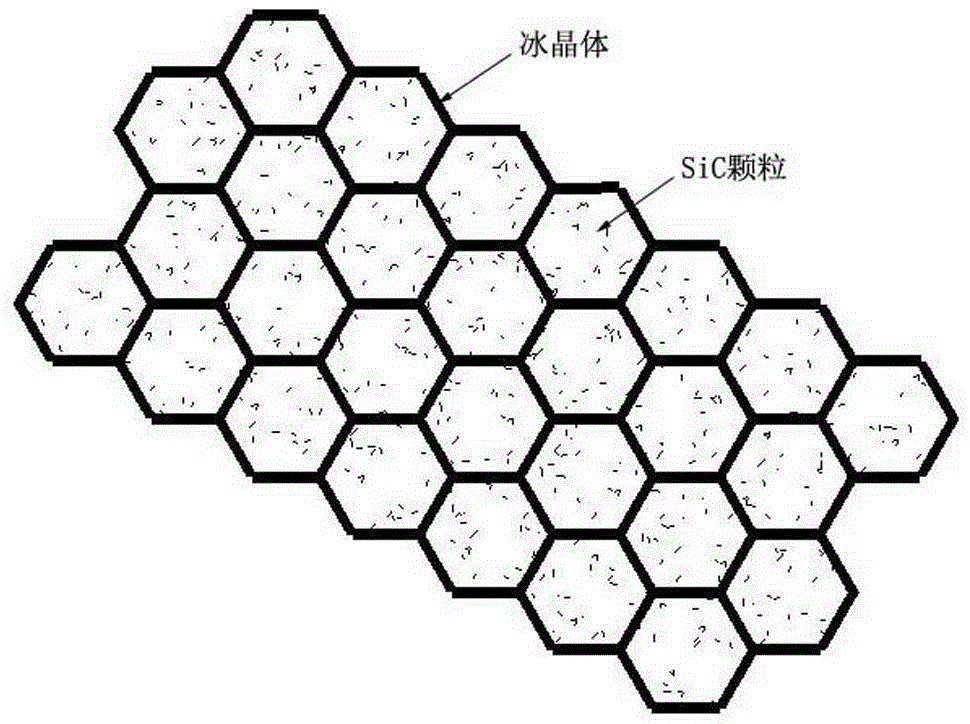

[0024] 1) Preparation of porous layered reinforcement materials with regular polygonal sheet structure by ice template method:

[0025] a) Preparation of SiC particle suspension: Mix SiC particles and deionized water at a mass ratio of 3:5.8, stir and mix with a magnetic stirrer for 30 minutes, then disperse with ultrasound for 3-5 minutes, and finally stir with a magnetic stirrer Mix for 30 minutes to obtain a uniform and well-dispersed SiC particle suspension;

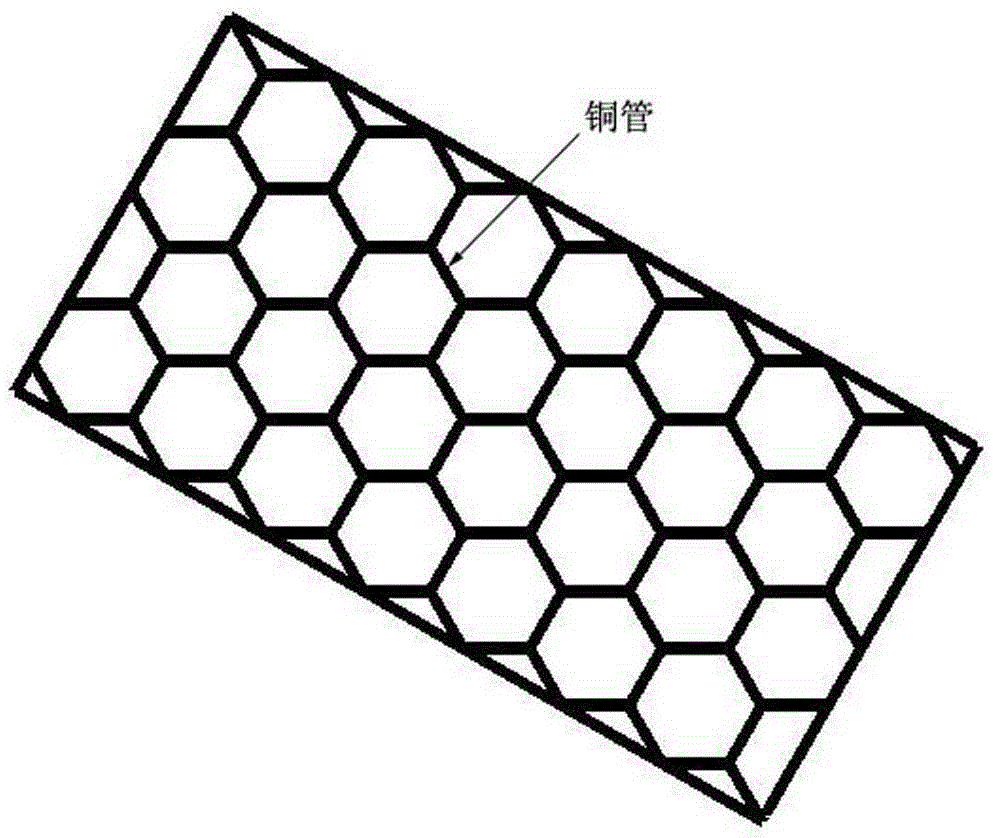

[0026] b) Make a frozen mold: The frozen mold includes a cooling base and a storage tank placed on the cooling base. The depth of the storage tank is 0.5 μm. The holes are all regular polygons, such as regular hexagons, regular pentagons, etc., such as figure 1 The shown regular hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com