Si-Mg composite insulation board and production method thereof

A composite thermal insulation and production method technology, applied in the direction of chemical instruments and methods, layered products, hydraulic material layered products, etc., can solve the problem of unsatisfactory anti-bending effect of finished products, weak adhesion of putty paint, and unfavorable transportation And construction and other issues, to achieve the effect of increasing the flexural performance, firm and reliable bonding, and unaffected production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

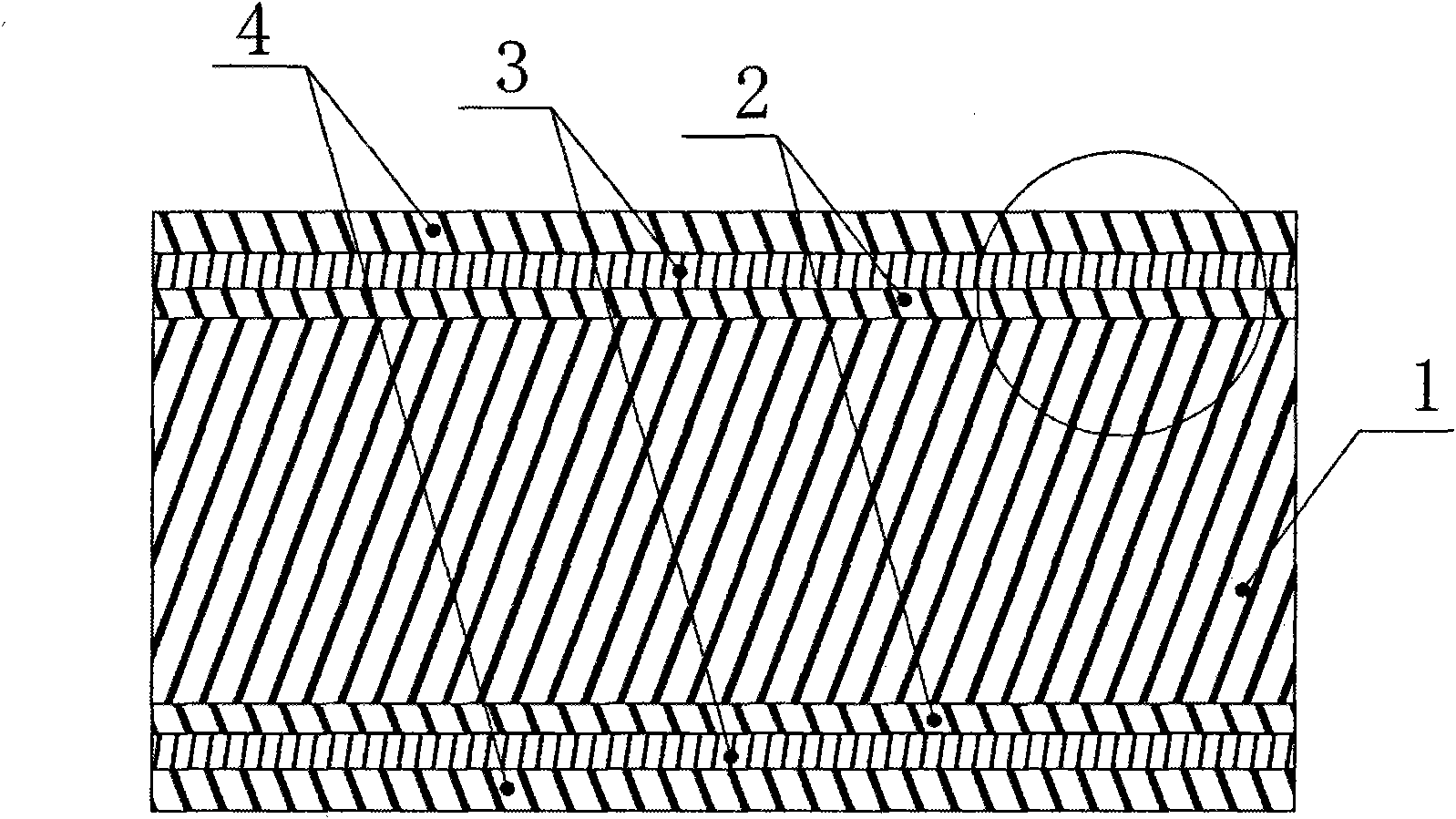

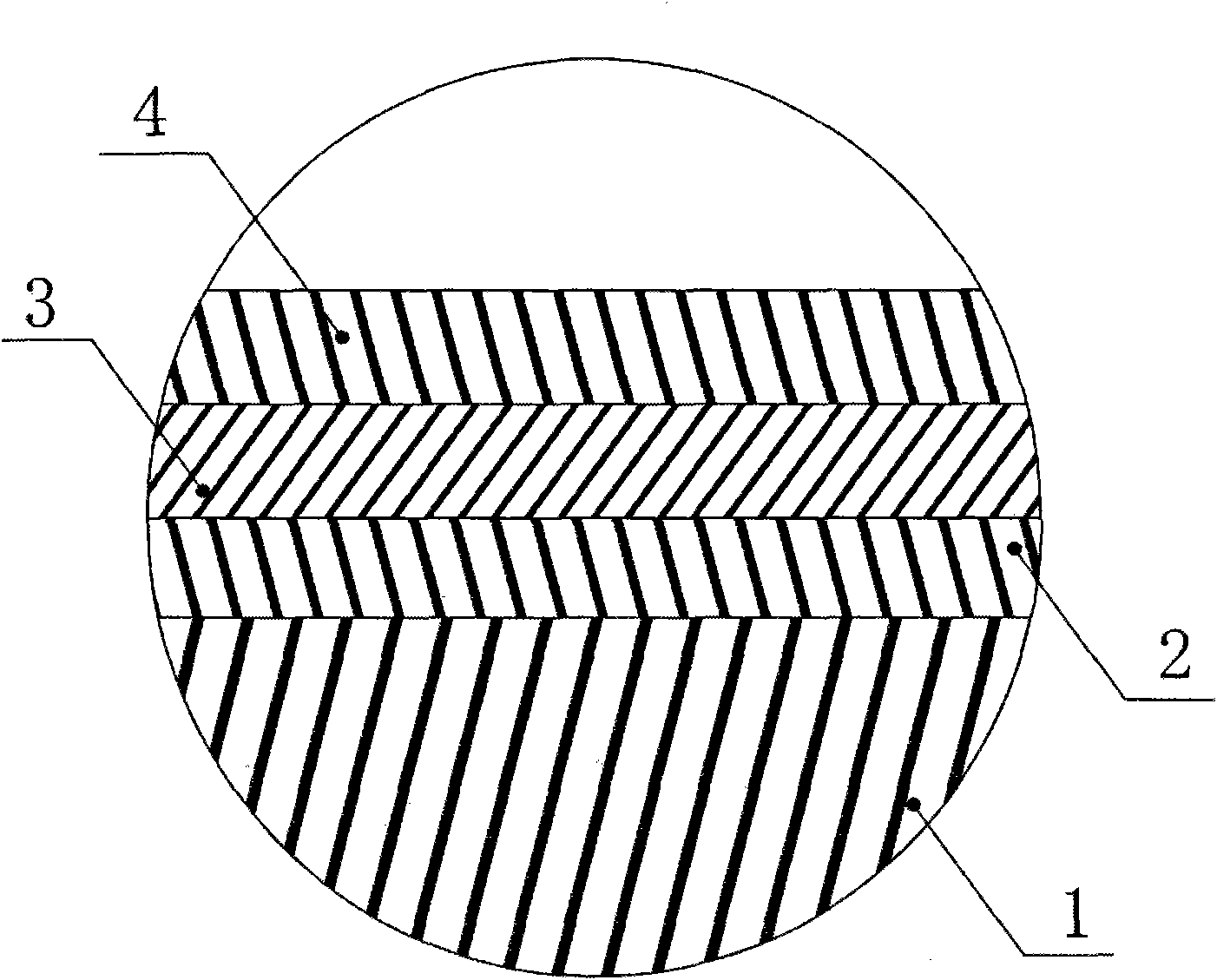

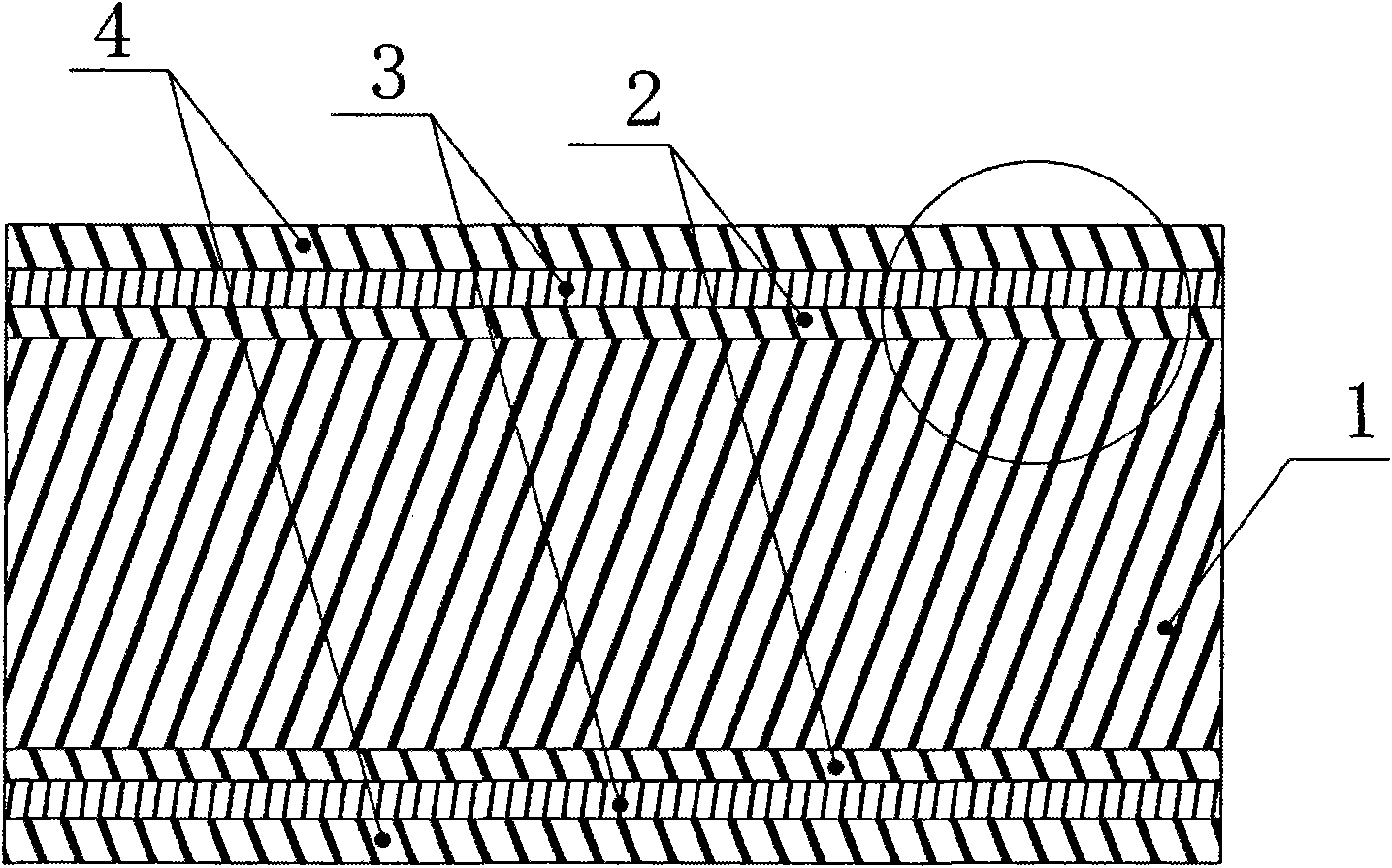

[0031] Embodiment 1: a kind of silicon-magnesium composite thermal insulation board, comprises composite silicate thermal insulation board 1, the upper and lower sides of described composite silicate thermal insulation board 1, is provided with the first magnesium oxychloride cement layer 2, Non-woven grid cloth 3, second magnesium oxychloride cement layer 4, wherein, the first magnesium oxychloride cement layer 2, non-woven mesh cloth 3, second magnesium oxychloride cement layer 2 on any side of the composite silicate insulation board 1 The total thickness of the cement layer 4 is 0.6 mm.

[0032] Its production method is:

[0033] (1) Brush the first layer of magnesium oxychloride cement slurry on both sides of the composite silicate insulation board 1, until the honeycomb holes on the surface of the composite silicate insulation board 1 are filled;

[0034] (2) each paste one deck non-woven grid cloth 3 on the first layer of magnesium oxychloride cement slurry;

[0035] (...

Embodiment 2

[0042] The component composition of described magnesium oxychloride cement slurry comprises by weight ratio:

[0043] 720 parts of magnesium oxide, 90 parts of magnesium chloride, 390 parts of water, 1 part of trisodium phosphate;

[0044] Get two composite silicate insulation boards 1 of 300mm*300mm*48mm, one of which is produced according to the production method of the present invention, and the first magnesium oxychloride cement layer 2 on any one side of the composite silicate insulation board 1, without The total thickness of the spun mesh cloth 3 and the second magnesium oxychloride cement layer 4 is 0.6 millimeters to obtain a silicon-magnesium composite insulation board, and the other piece is not processed. The flexural and compressive strength data comparison of the two is:

[0045] Composite silicate insulation board 1: flexural strength 0.21MPa, compressive strength 0.42Mpa;

[0046] Silicon-magnesium composite thermal insulation board: the flexural strength is 0...

Embodiment 3

[0048] The component composition of described magnesium oxychloride cement slurry comprises by weight ratio:

[0049] 700 parts of magnesium oxide, 110 parts of magnesium chloride, 390 parts of water, 1 part of trisodium phosphate; Get 1 two pieces of composite silicate insulation boards of 300mm*300mm*48mm, one of them is produced according to the production method of the present invention, and the composite silicon The total thickness of the first magnesium oxychloride cement layer 2, the non-woven grid cloth 3, and the second magnesium oxychloride cement layer 4 on any one side of the salt insulation board 1 is 0.6 millimeters, obtains the silicon-magnesium composite insulation board, and the other does not After processing, the comparison of the flexural and compressive strength data of the two is as follows:

[0050] Composite silicate insulation board 1: flexural strength 0.21MPa, compressive strength 0.42Mpa;

[0051] Silicon-magnesium composite thermal insulation boar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com