Printable coating for lithium ion battery wrapping film and preparation method of printable coating

A lithium-ion battery, printing coating technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problem of affecting the printing effect of UV ink, reducing the surface energy of the raw material of the wrapping film, poor surface adhesion, etc. problem, to achieve the effect of not easy to slip, ensure reliability, and strong surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of a printable coating for a lithium-ion battery wrapping film.

[0038] (1) Composition of printable coatings for lithium-ion battery wrapping films.

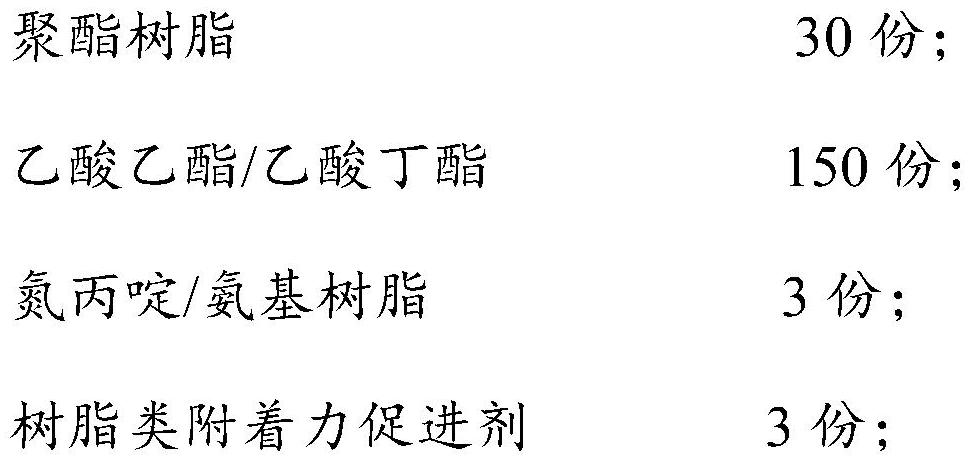

[0039]

[0040] The polyester resin has the following characteristics: a relative molecular weight of 20,000, a glass transition temperature of 65°C, an acid value of 5 mgKOH / g, a hydroxyl value of 5 mgKOH / g, and a linear structure.

[0041] Resin-based adhesion promoters have the following characteristics: phosphate esters with polyester as the main chain.

[0042] (2) Preparation of printable coatings for lithium-ion battery wrapping films.

[0043] Step S1. Put 150 parts of ethyl acetate / butyl acetate mixed solvent and 30 parts of polyester resin into the temperature-controllable reactor to completely dissolve the polyester resin;

[0044] Step S2. Weigh the dissolved polyester resin in the glue mixing container, add 3 parts of crosslinking agent aziridine / amino resin mixture, 3 parts of p...

Embodiment 2

[0046] Example 2: Preparation of a printable coating for a lithium-ion battery wrapping film.

[0047] (1) Composition of printable coatings for lithium-ion battery wrapping films.

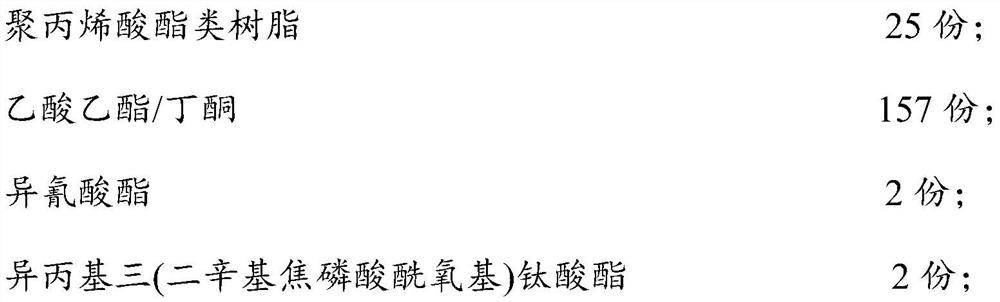

[0048]

[0049] The polyacrylate resin has the following characteristics: a relative molecular weight of 30,000, a glass transition temperature of 78° C., an acid value of 3.5 mgKOH / g, and a BMA / MMA copolymer.

[0050] (2) Preparation of printable coatings for lithium-ion battery wrapping films.

[0051] Step S1. Put 157 parts of ethyl acetate / butanone mixed solvent and 25 parts of polyacrylate resin into the temperature-controllable reactor to completely dissolve the polyacrylate resin;

[0052] Step S2. Weigh the dissolved polyacrylate resin in the glue mixing container, add 2 parts of crosslinking agent isocyanate, 2 parts of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, and stir to form a uniform printing coating liquid;

[0053] Step S3. The printable coating liquid is coated...

Embodiment 3

[0054] Example 3: Preparation of a printable coating for a lithium-ion battery wrapping film.

[0055] (1) Composition of printable coatings for lithium-ion battery wrapping films.

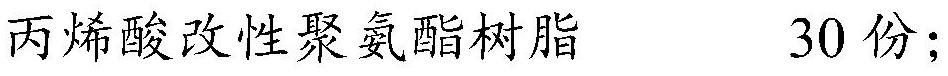

[0056]

[0057]

[0058] Acrylic modified polyurethane resin has the following characteristics: relative molecular weight is 10,000, glass transition temperature is 60°C, acid value is 5 mgKOH / g, hydroxyl value is 5 mgKOH / g, and straight chain structure.

[0059] Resin-based adhesion promoters have the following characteristics: phosphate esters with polyester as the main chain.

[0060] (2) Preparation of printable coatings for lithium-ion battery wrapping films.

[0061] Step S1. Put 150 parts of acetone solvent and 30 parts of acrylic modified polyurethane resin into the temperature-controllable reactor to completely dissolve the polyester resin;

[0062] Step S2. Weigh the dissolved polyester resin in the glue mixing container, add 3 parts of cross-linking agent epoxy resin, 3 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com