Modified pultrusion composite material and preparation method thereof

A composite material and modification technology, applied in the field of composite material science, can solve problems such as blockage of molds and uneven resin polymerization, and achieve the effects of increasing filler content, reducing production fluctuations, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

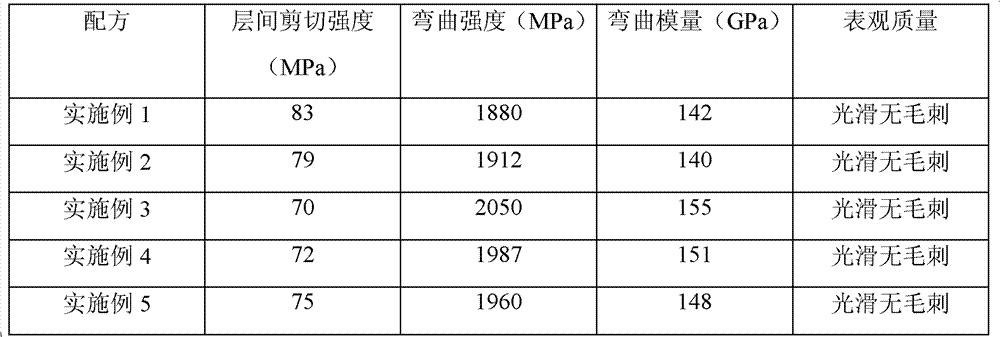

Examples

Embodiment 1

[0034] A modified pultruded composite material and its processing method are as follows:

[0035] Combine 100 parts of bisphenol A epoxy vinyl ester resin with a viscosity of 10000CPS, 200 parts of styrene, 40 parts of 300 mesh heavy calcium carbonate, 2 parts of benzoyl peroxide, 59112 parts of fluorine-containing processing aid PPAFX, stearin Add 1 part of zinc acid to the container and stir for 60 minutes at room temperature with pneumatic stirring; set each temperature section of the pultrusion die to 100℃, 130℃, 150℃, and set the number of glass fiber yarns to 300mm 2 0.5 times the cross-sectional area of the round rod, which is 150 strands, pour the polymer into the dipping tank, set the pultrusion speed to 0.15m / min, immerse and pull the glass fiber, solidify and shape, and measure the ash content of 55%, that is, glass fiber yarn 422 copies.

Embodiment 2

[0037] A modified pultruded composite material and its processing method are as follows:

[0038] Combine 100 parts of bisphenol A epoxy vinyl ester resin with a viscosity of 1000CPS, 10 parts of glycidyl methacrylate, 0.1 part of tert-butyl peroxymaleate, 21 parts of fluorine-containing processing aid PPA HTN92G35DH, and calcium stearate Add 0.5 part to the container, stir for 30min at room temperature with pneumatic stirring; set each temperature section of the pultrusion die to 100℃, 130℃, 150℃, and set the number of carbon fiber yarns to 300mm 2 0.6 times the cross-sectional area of the round rod, or 180 strands, pour the polymer into the dipping tank, set the pultrusion speed to 0.3m / min, immerse and pull the carbon fiber, solidify it, and measure the ash content of 65%, that is, the carbon fiber yarn is 208 Copies.

Embodiment 3

[0040] A modified pultruded composite material and its processing method are as follows:

[0041] 100 parts of bisphenol A epoxy vinyl ester resin with a viscosity of 5500 CPS, 105 parts of 1,4-butanediol diglycidyl ether, 30 parts of 300 mesh talc, 50 parts of 300 mesh heavy calcium carbonate, peroxide 0.5 part of tert-butyl tert-valerate, 0.5 part of dicumyl peroxide, 20.1 part of fluorine-containing processing aid PPA HTN92G45DH, 1 part of PE wax, add to the container, use pneumatic stirring to close and stir at room temperature for 45 minutes; pultrude the mold Each temperature section is set to 100℃, 130℃, 150℃, and the number of basalt fiber yarns is set to 300mm 2 The cross-sectional area of the round rod is 0.8 times that is 240 strands, the polymer is poured into the dipping tank, the pultrusion speed is set to 0.2m / min, the basalt fiber is impregnated and pulled, solidified, and the ash content is measured to be 80%, that is, basalt fiber yarn 1148 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com