Crude benzene recovery process intelligent optimization control system

A control system and intelligent optimization technology, applied in the fields of comprehensive factory control, absorption purification/separation, organic chemistry, etc., can solve problems such as large fluctuations, low recovery rate of crude benzene, high benzene content, etc., to optimize the control process and control system , Reduce the fluctuation of the production process and improve the efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

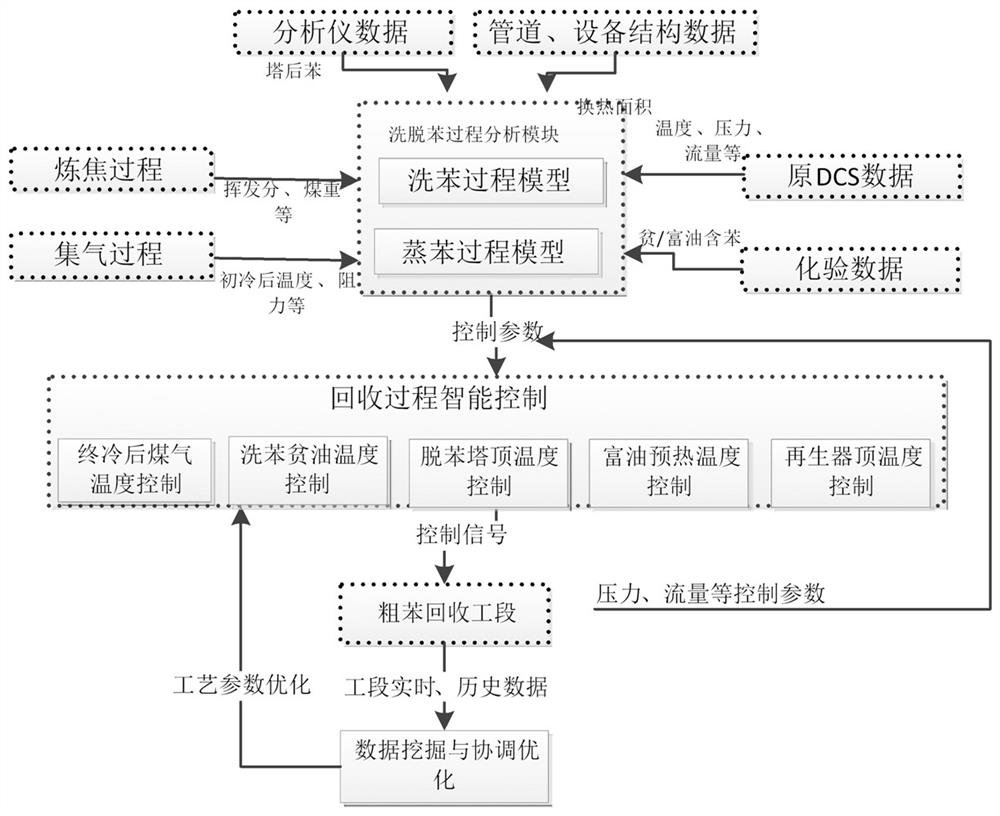

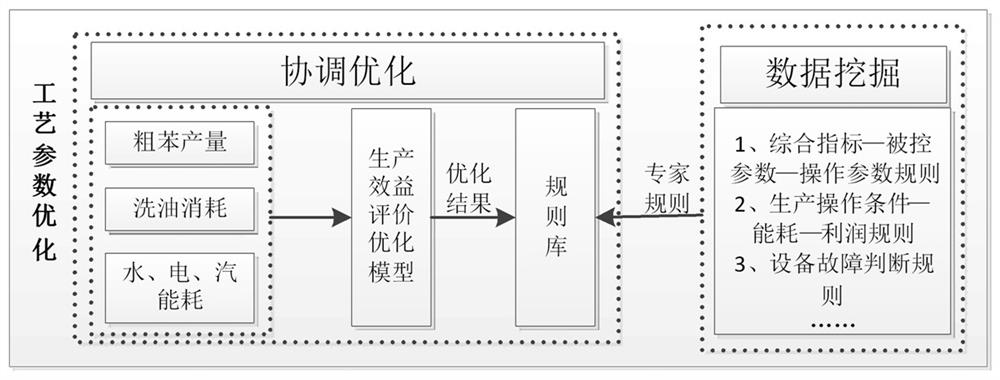

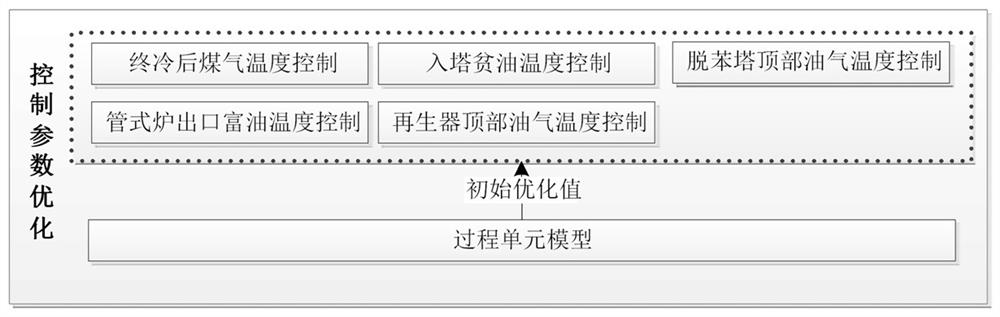

[0017] Such as figure 1 Shown is the schematic diagram of the system modules of the present invention: the intelligent optimization control system for this crude benzene recovery process provided by the present invention includes an analysis module for the elution benzene process, an intelligent control module for the recovery process and a data mining and coordination optimization module; the benzene elution process The analysis module, the recovery process intelligent control module, and the data mining and coordination optimization module are connected in series; the benzene elution process analysis module is used to conduct mass conservation, energy conservation law and gas-liquid phase mass transfer theory analysis based on basic data, and establish recovery process intelligence. Control module, feedforward calculation of each control parameter value and send it to the established recovery process intelligent control module; recovery process intelligent control module is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com