Cooling device for manufacturing process of electric arc printing additional material

A technology for additive manufacturing and cooling devices, applied in auxiliary devices, manufacturing tools, additive processing, etc., can solve the problems of low cooling efficiency, poor cooling effect, and accelerated cooling of workpieces in cooling devices, achieving good cooling effect and simple structure Reliable, Cooling Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

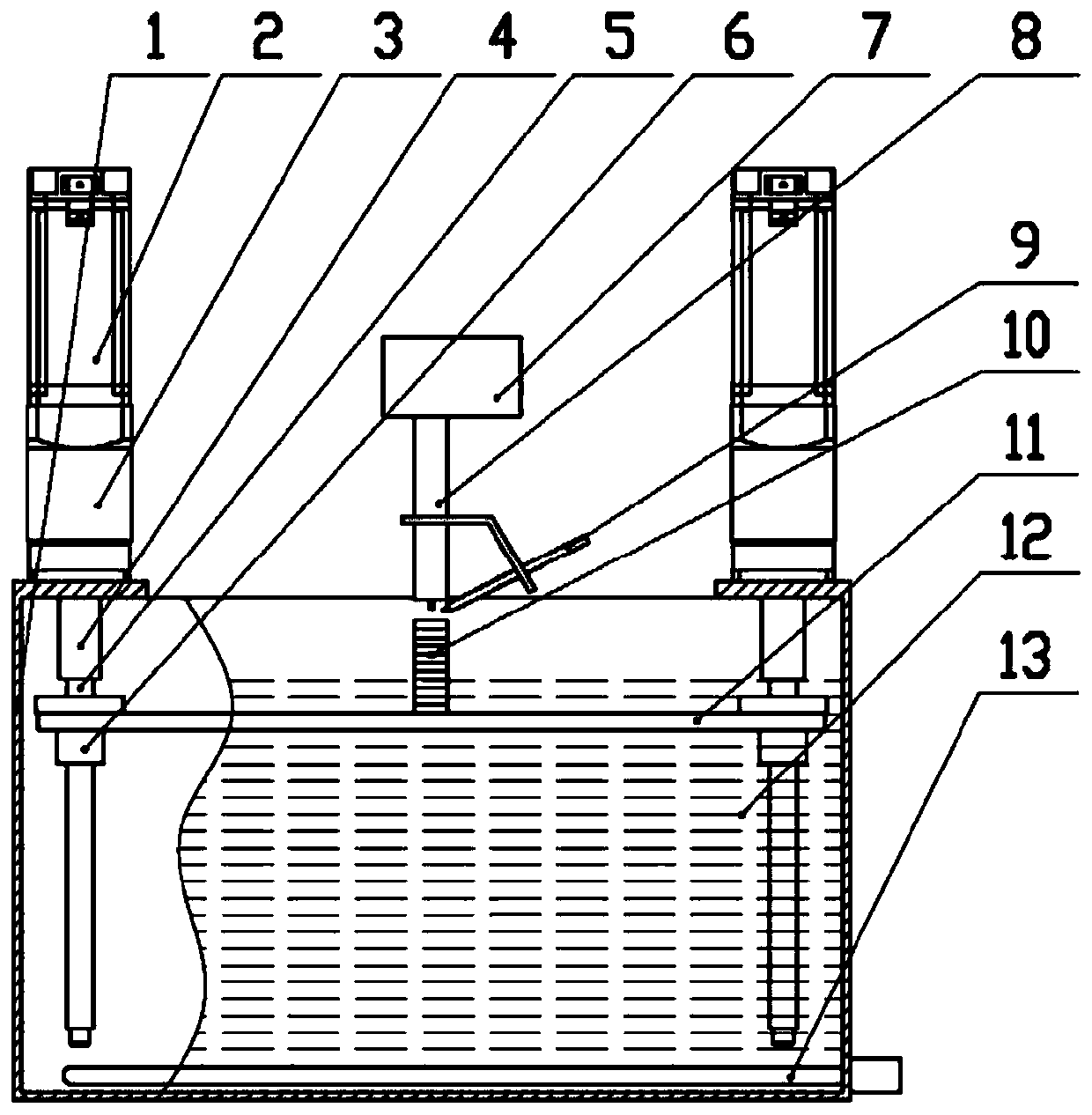

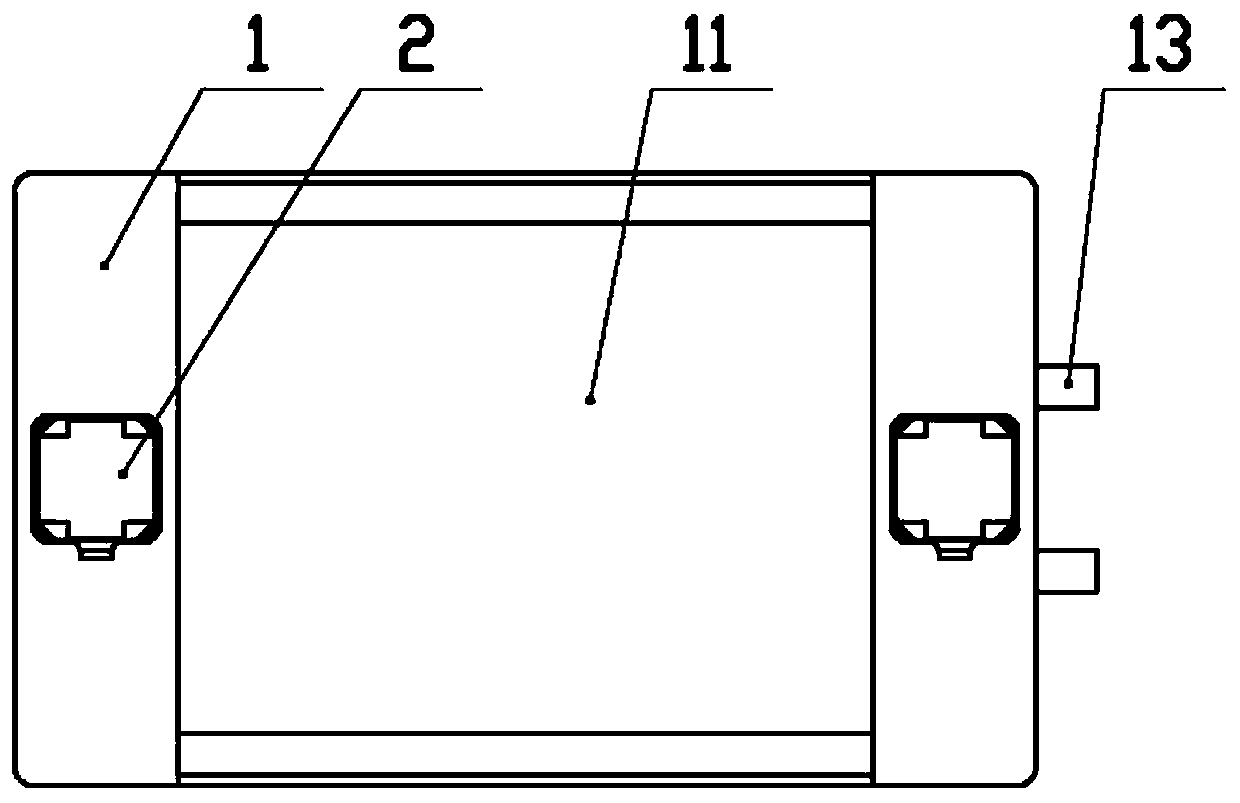

[0024] see Figure 1-2 As shown, the present invention provides a cooling device used in the arc printing additive manufacturing process. A driving mechanism is installed symmetrically above the cooling tank 1. The driving mechanism is connected through a coupling 4 and drives the lifting mechanism to move up and down in the cooling tank 1. Cooling liquid 12 is injected into the cooling tank 1, and the bottom of the cooling tank 1 is provided with a cooling coil 13, and the cooling coil 13 injects cooling water through a water pump, and the cooling water is used to take away the heat absorbed by the cooling liquid 12.

[0025] Further, the drive mechanism includes a servo motor 2, the lifting mechanism includes a lead screw 5 and a lifting base plate 11, the servo motor 2 is connected to the reducer 3, and the lower output shaft of the reducer 3 is connected to the lead screw 5 through a coupling 4 to drive the lead screw 5 rotates, the lead screw 5 passes through the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com