Use method of tunnel lining maintenance film-coating trolley

A film-coated trolley and lining technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of water spray curing difficult to achieve expectations, the concrete surface cannot be guaranteed to be wet, etc., to improve the construction progress and quality, and optimize the production environment. , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

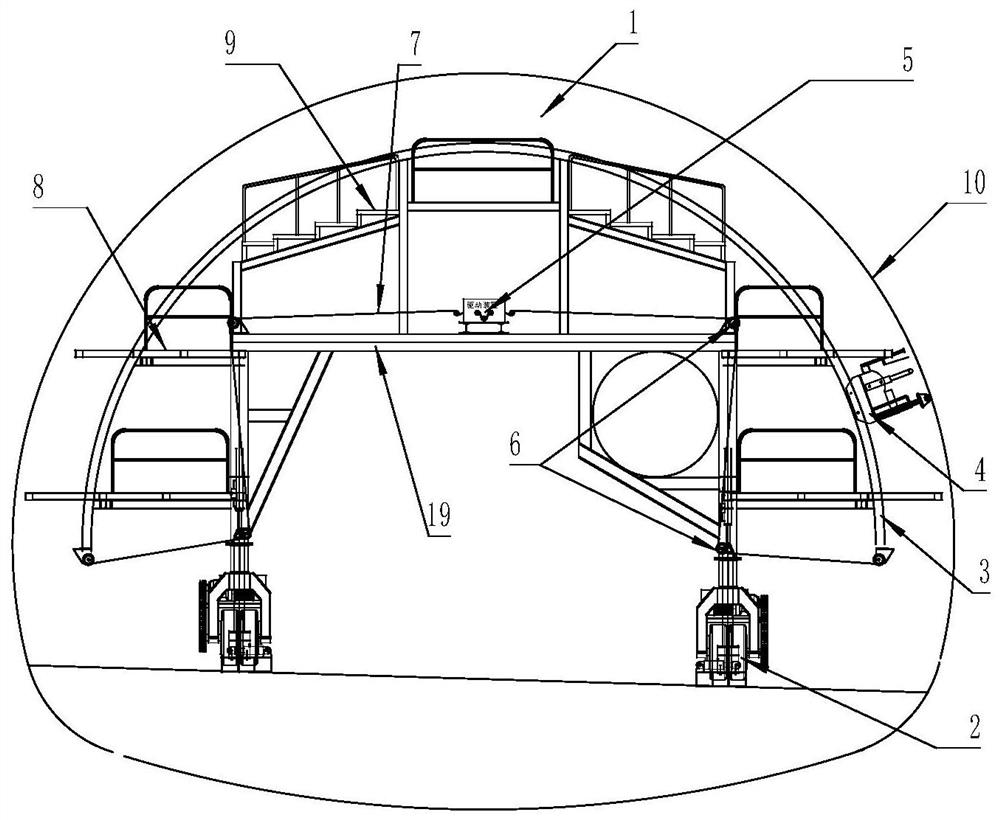

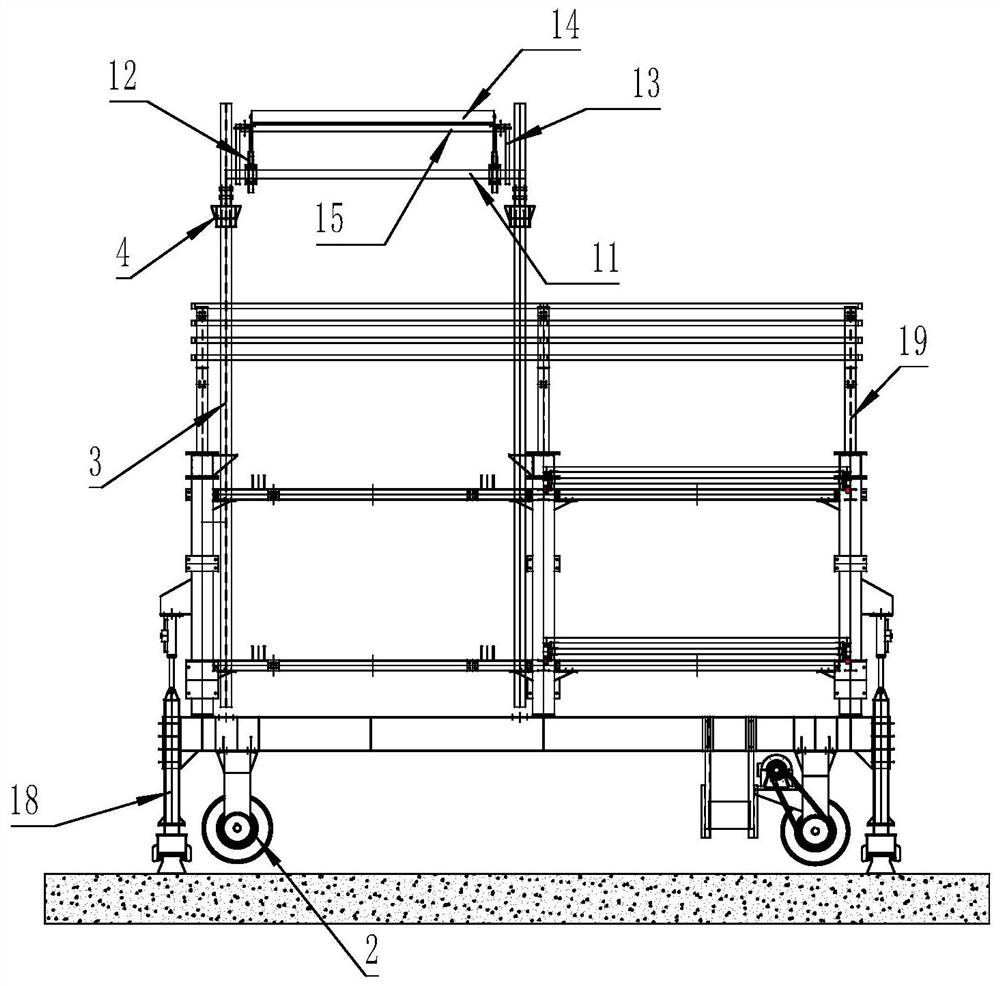

[0018] At least two gantry frames 19 are arranged at the front end and the rear end of the lining film-covered maintenance trolley 1, and the lower ends of the columns on both sides of the gantry frame 19 are respectively provided with trolley lifting support frames 18; Bottom beams are arranged between them, and walking wheels 2 are respectively set between the two ends of the bottom beams on both sides and the ground; telescopic platforms 8 are arranged symmetrically in the lower and middle parts of both sides of the lining film-covered maintenance trolley 1, and the top of the lining film-covered maintenance trolley 1 The top platform 9 is symmetrically arranged on both sides, and the top platform 9 and the telescopic platform 8 are respectively set as manual operation platforms; the outer side of the lining film-covered maintenance trolley 1 corresponds to the lining concrete inner wall 10. A pair of arc-shaped trolley tracks 3, a pair of trolley A trolley channel is set be...

Embodiment 2

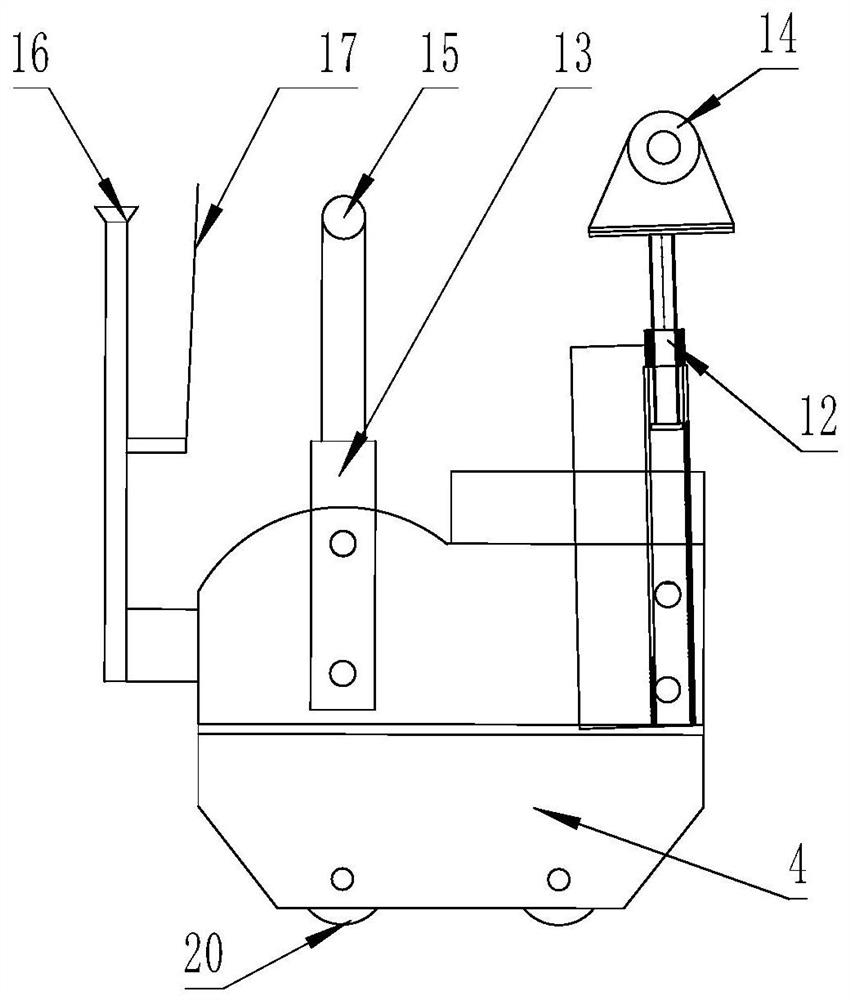

[0023]After the film coating at the bottom of the film-coated roll is completed, the film-coating pressure roller 14 is stretched out through the automatic lifting frame 12, and the film-coating pressure roller 14 is laminated by pressing the back of the film and lining the inner wall of the concrete 10. At the same time, open the The valve of the airflow cleaning nozzle 16 and the starting trolley driving device 5 pull the film-coated trolley 4 to move upward along the trolley track 3 through the pull rope 7; during the walking process of the film-coated trolley 4, the airflow cleaning nozzle 16 will pass the airflow to the surface of the lining concrete inner wall 10. The dust is cleaned continuously; at the same time, the film of the film roll on the film roll insertion shaft 15 is pulled out, the film pressure roller 14 rotates, and the top presses the film and the inner wall of the lining concrete 10 for continuous film coating; When the trolley 4 runs to the other end of ...

Embodiment 3

[0025] After the film-covering maintenance in the first construction section, the film-covering trolley 4 returns to the starting end, lowers the lining film-covering maintenance trolley 1 through the trolley lifting support frame 18, and runs forward through the traveling wheels 2 until it is less than the width of the film-covering roll 1. Stop after reserving the width of the lap joint, repeat the process of film maintenance in the first construction section above, and carry out the film maintenance construction of the rear lining concrete inner wall 10 continuously by the film coating trolley 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com