Graphene-based composite antibacterial material and preparation method thereof

A composite antibacterial and graphene technology, applied in botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of easy precipitation and easy volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

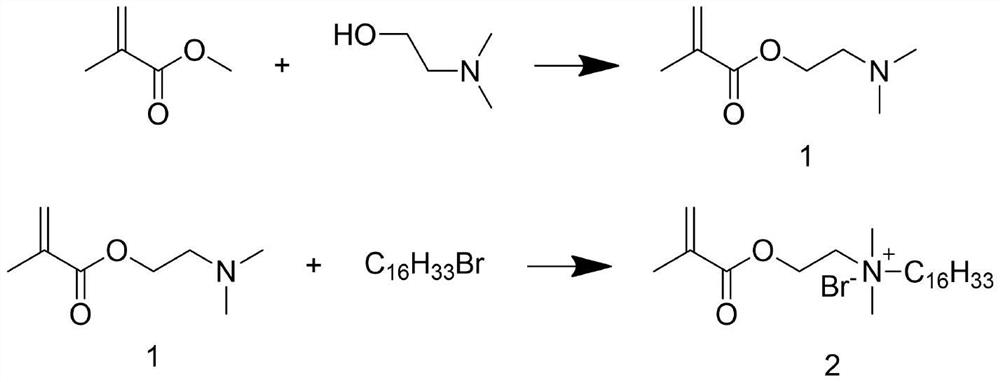

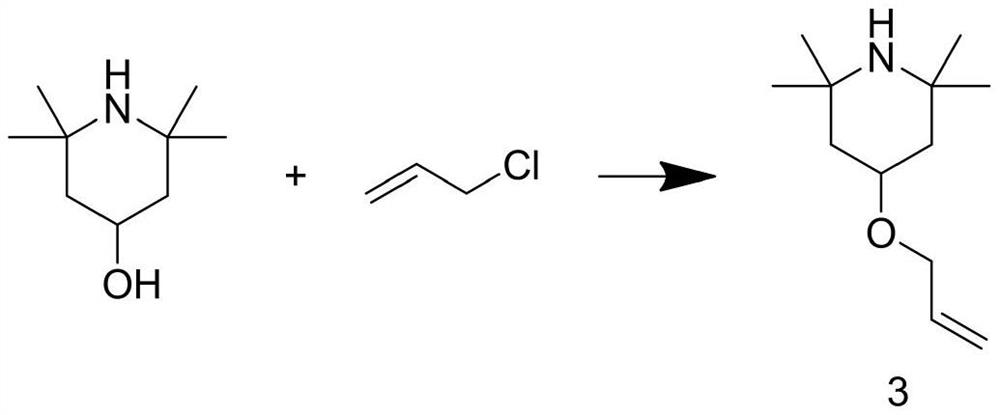

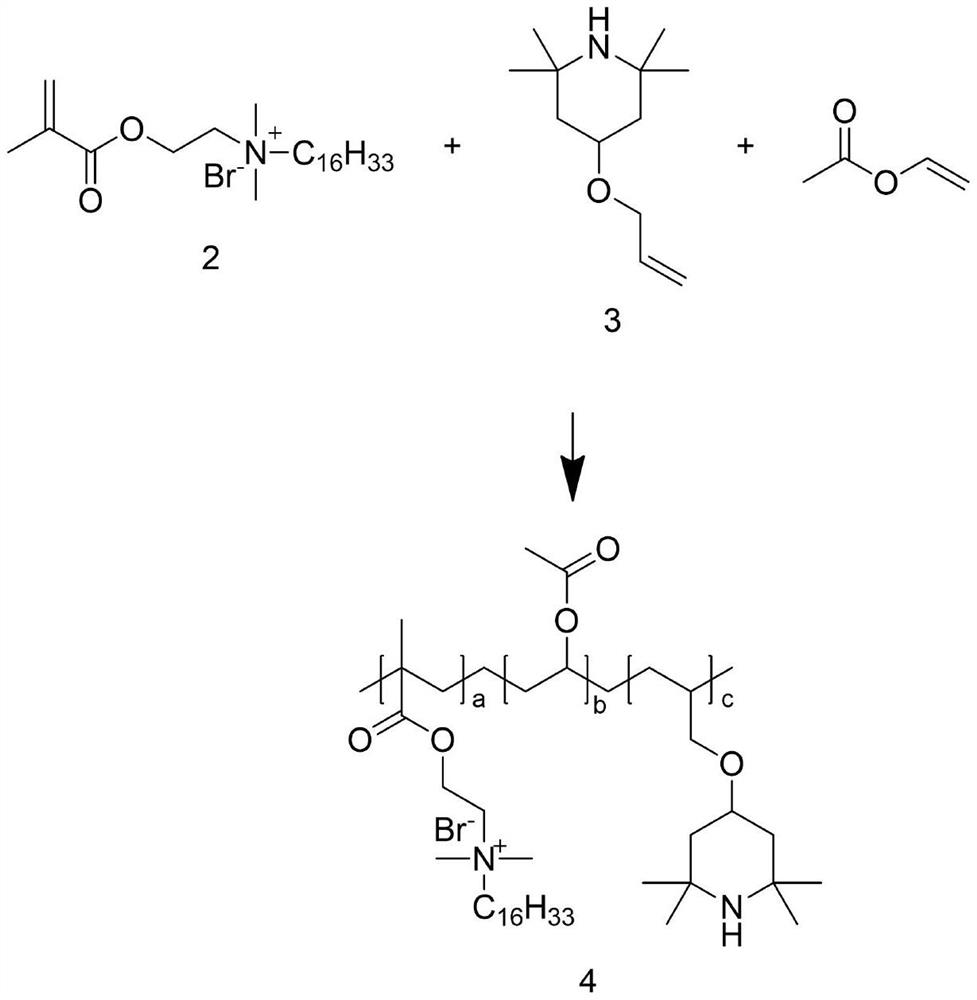

Method used

Image

Examples

Embodiment 1

[0035] A kind of composite antibacterial material based on graphene, comprises the steps:

[0036] Step S1: Disperse the modified graphene in N,N-dimethylformamide, add an antibacterial enhancer and 4-dimethylaminopyridine, and react at a speed of 200r / min and a temperature of 100°C After 5h, remove the filtrate by filtration, and dry the filter cake;

[0037] Step S2: Soak the filter cake in sodium hypochlorite solution, adjust the pH value to 7, soak for 1 hour, filter and dry to obtain a composite antibacterial material.

[0038] Modified graphene is made by the following steps:

[0039] Step A1: Add graphite, sodium nitrate, and concentrated sulfuric acid into the reaction kettle, stir for 20 minutes under the condition of rotating speed of 150r / min and temperature of 0°C, then add potassium permanganate and raise the temperature to 10°C, continue Stir for 1 hour, heat up to 35°C, keep warm for 20 minutes, add deionized water, heat up to 95°C, keep warm for 10 minutes, add...

Embodiment 2

[0046] A kind of composite antibacterial material based on graphene, comprises the steps:

[0047] Step S1: Disperse the modified graphene in N,N-dimethylformamide, add an antibacterial enhancer and 4-dimethylaminopyridine, and carry out the reaction at a speed of 200r / min and a temperature of 110°C After 6h, remove the filtrate by filtration, and dry the filter cake;

[0048] Step S2: Soak the filter cake in sodium hypochlorite solution, adjust the pH value to 7, soak for 1.3 hours, filter and dry to obtain a composite antibacterial material.

[0049] Modified graphene is made by the following steps:

[0050] Step A1: Add graphite, sodium nitrate, and concentrated sulfuric acid into the reaction kettle, stir for 25 minutes under the condition of rotating speed of 180r / min and temperature of 0°C, then add potassium permanganate and raise the temperature to 13°C, continue Stir for 1.3 hours, raise the temperature to 38°C, keep it warm for 25 minutes, add deionized water, rais...

Embodiment 3

[0057] A kind of composite antibacterial material based on graphene, comprises the steps:

[0058] Step S1: Disperse the modified graphene in N,N-dimethylformamide, add an antibacterial enhancer and 4-dimethylaminopyridine, and carry out the reaction at a speed of 300r / min and a temperature of 120°C After 8h, remove the filtrate by filtration, and dry the filter cake;

[0059] Step S2: Soak the filter cake in sodium hypochlorite solution, adjust the pH value to 7, soak for 1.5 hours, filter and dry to obtain a composite antibacterial material.

[0060] Modified graphene is made by the following steps:

[0061] Step A1: Add graphite, sodium nitrate, and concentrated sulfuric acid into the reaction kettle, stir for 30 minutes under the condition of rotating speed of 200r / min and temperature of 0°C, then add potassium permanganate and raise the temperature to 15°C, continue Stir for 1.5 hours, raise the temperature to 40°C, keep it warm for 30 minutes, add deionized water, rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com