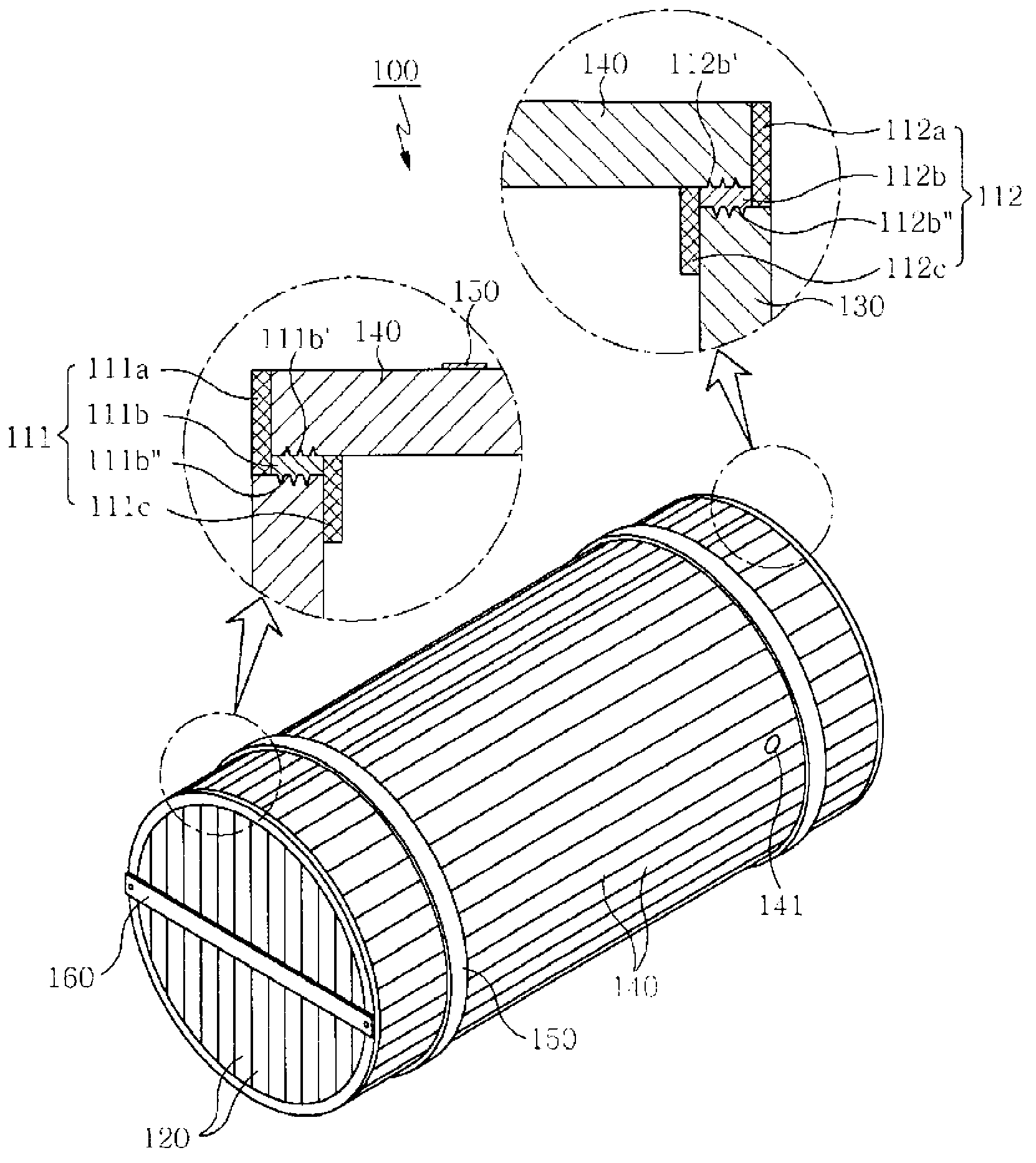

Wooden barrel for storing liquid consumables

A technology of food storage and wooden barrels, which is applied in the direction of liquid distribution, liquid flow control devices, rigid containers, etc., to achieve the effect of increasing capacity, improving production efficiency, and easy supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

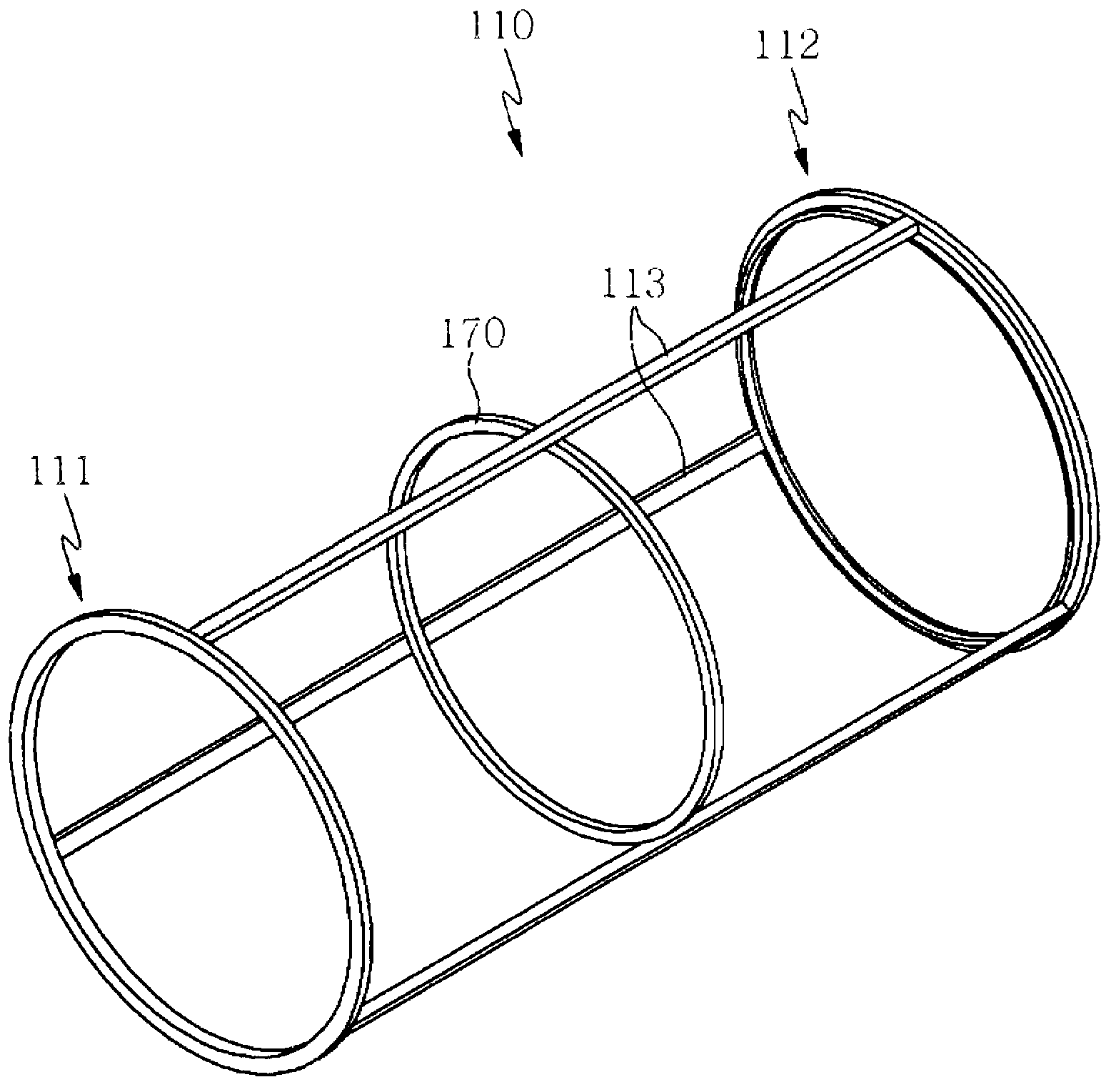

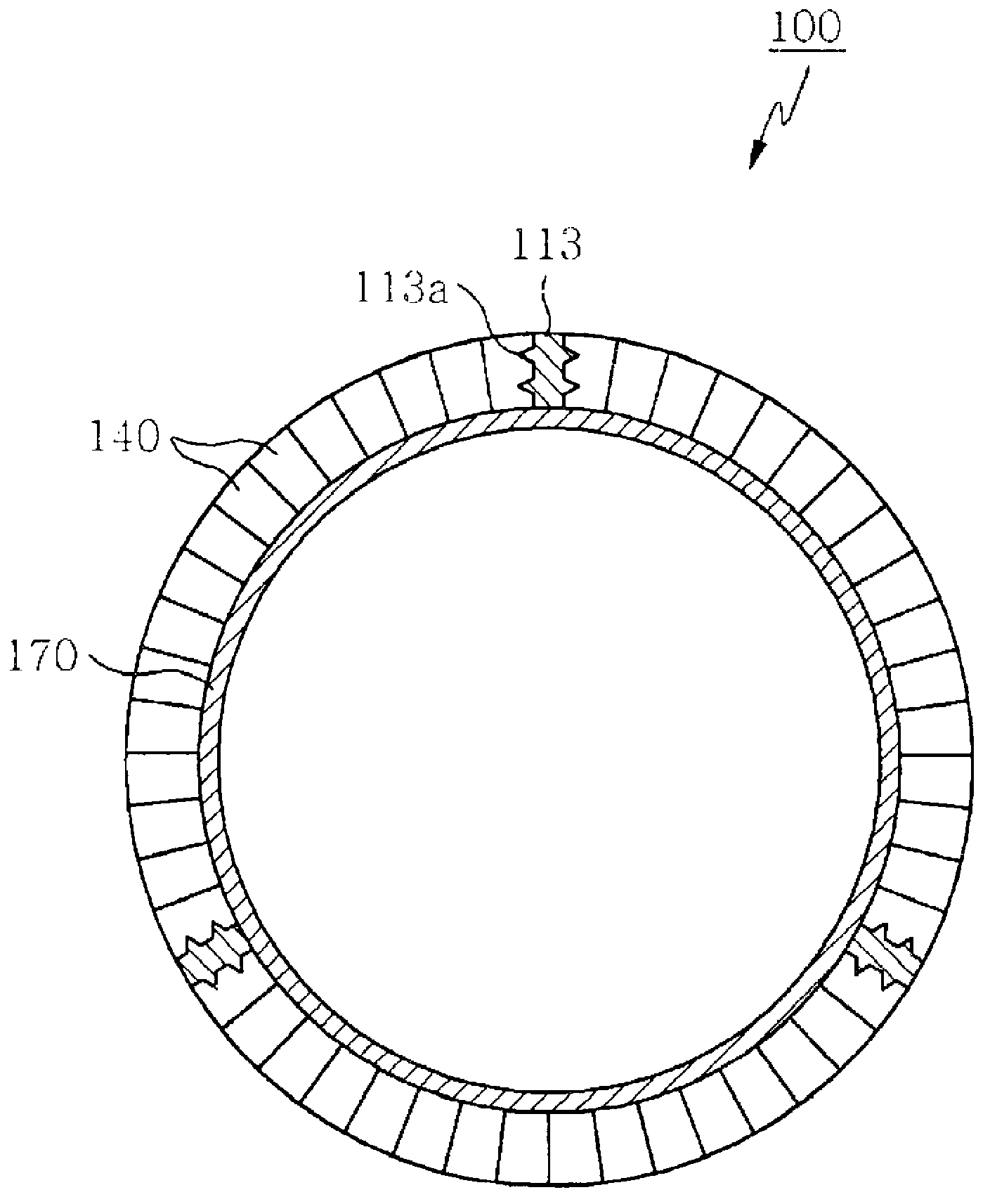

Method used

Image

Examples

Embodiment 1

[0102] Utilize the used pine of the present invention, the groove wooden barrel wine of Korean pine to make

[0103] After logging, the logs used for making trough barrels should be dried for 60 days for pine trees and 45 days for red pine trees. After the craft company dug the groove, it was dried for 13 days. The age of the cut logs was 23 years for pine and 19 years for red pine, and the diameter of the heartwood was 7 cm for pine and 9 cm for red pine. The upper surface with the groove of the grooved barrel is smoothed with a plane so that it can be sealed with a glass plate. Pine resin was collected from pine trees in Yeoju-gun, Gyeonggi-do, and 30% (w / v) of pine resin was dissolved in 85% ethanol, and the residue was precipitated, and then the clarified solution was used. For the surface coating of the troughs, 30% pine resin ethanol solution (w / v) was fully applied to the surface of the pine and red pine troughs and then dried for storage experiments. The turpentine ...

experiment example 1

[0108] Utilize the pine and red pine used in the liquid food storage barrel of the present invention to make pine and red pine tank barrels with pine resin coated on the surface, and use a leak that can be analyzed during storage, and it is easy to distinguish The 48.2% (v / v) ethanol solution with less off-flavor of liquor quality improvement effect was used as liquor for storage. The tank barrel injection volume of the stored wine is injected into the stored wine 30 minutes after the initial injection by the absorption of the tank barrel itself so as to reserve the depth of the headspace (from the tank entrance of the tank barrel to the storage tank) The distance between the wine water level) reaches 1cm.

[0109] After pouring the stored wine, the upper surface of the tank barrel with the tank is sealed with paraffin and the glass plate, and then a heavy object is pressed on the glass plate to seal. According to the analysis of the storage time, the leakage of alcohol is de...

Embodiment 2

[0114] Conduit filling of pine staves used in the present invention

[0115] In order to compare the degree of diffusion of water and ethanol by using the internal conduit of the pine barrel stave used in the present invention, the pine board is respectively clamped on 2 water tanks, and after the ink pigment is mixed with water and 80% ethanol solution respectively, from From the end of the plate to a height of 1cm, pour the coloring water and the coloring ethanol solution into the water tank, and observe the degree of diffusion to the inner duct of the barrel stave within 3 hours. Diffusion to the inner duct is performed by sawing off the specified height step by step with a saw, and the height at which 50% of the cut surface is dyed with pigment is taken as the diffusion distance. As shown in Table 3 below, unlike the pigment diffusion distance on the outside of the plate, the pigment diffusion distance on the inside is short, while the diffusion distance of the 80% ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com