Pine resin collector

A technology for pine resin and pine trees, applied in the field of economic forestry, can solve the problems of destruction of pine forests, pine tree death, unsuitable for large-scale production and processing, etc., to achieve the effect of protecting the environment, maximizing economic benefits, and maximizing social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

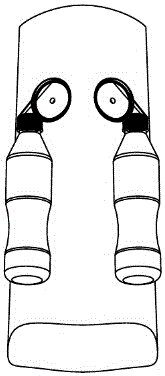

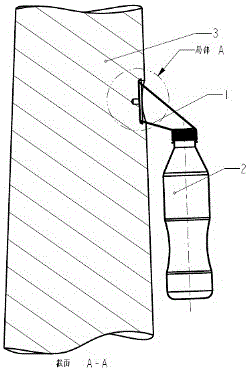

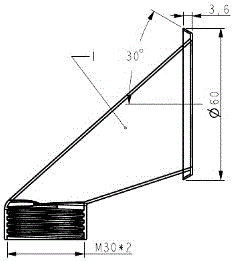

[0016] Embodiment 1: a kind of pine resin grease receiver, described grease receiver is made up of grease receiver interface 1 and collecting bottle 2, and connection relation is: the oblique upper part peripheral circle part of the grease receiver interface 1 and the drill of pine tree 3 The inner circumference of the hole is connected with an interference fit, and the oblique lower part of the interface 1 of the fat receiver is connected with the upper socket of the collection bottle 2 . The oblique upper portion of the grease receiver interface 1 is an oblique cone, and the outer circumference of the oblique upper portion of the oblique cone has a flange. The flange of the described grease receiver interface 1 is in the shape of a cone, the angle between the horizontal axis of the cone shape and the vertical axis is 30 degrees, the length of the flange in the horizontal direction of the cone shape is 3.6 mm, the flange The diameter of the small end is Φ55 mm, and the diamet...

Embodiment 2

[0017] Embodiment 2: The thickness of PP is 1.2 mm. The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0018] Embodiment 3: The thickness of PP is 1.5 mm. The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com