Method for preparing botanical solvent

A technology of plant sources and solvents, applied in botany equipment and methods, plant growth regulators, animal repellents, etc., can solve the problems of high price, unsatisfactory solubility, limitations, etc., and achieve high yield and production storage The operation is safe, reliable and compatible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

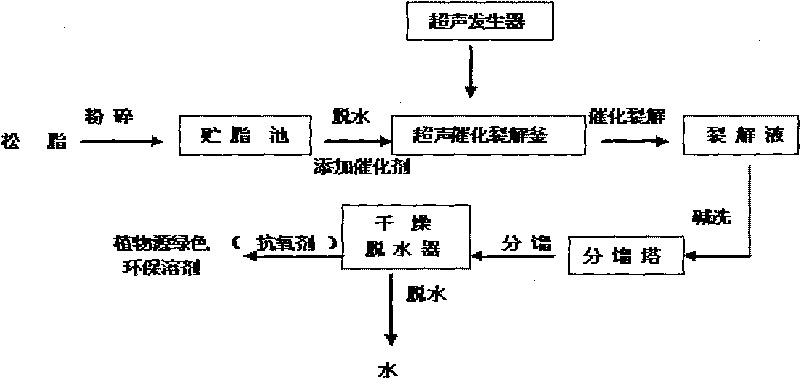

Method used

Image

Examples

Embodiment 1

[0033] Weigh 100 kg of masson pine pine resin, crush it and add it to the fat storage tank to remove water; mix the dehydrated pine resin with 0.5 kg of MGG catalytic cracking catalyst; in the isolation of air, ultrasonic frequency 100KHz, output power 500W, temperature 250 ℃ Under the condition of ultra-sonic cracking for 4 hours, the lysate was washed with 10 kg of 5% liquid alkali aqueous solution, and the oil and water were separated by standing. The separated oil phase was fractionated by a fractionating tower, and the fraction between 80 and 260 ° C was collected; the water separator was dehydrated (the mass percent of water in the cut is 0.35%), obtain 79 kilograms of cuts, add 0.8 kilograms of antioxidant 2 in the cuts, 6-di-tert-butyl-p-cresol dissolves evenly, prepares and obtains the plant source green solvent.

[0034] The composition of the detected plant source green solvent is pinene containing 28% by mass, D-limonene by 30% by mass, longifolene by 9% by mass, ca...

Embodiment 2

[0036] Weigh 100 kg of masson pine resin, crush it and add it to the fat storage tank to remove water; mix the dehydrated resin with 0.5 kg of H4[SiW12O40]xH2O silicotungstic acid (x is 1-12) catalyst; , under the conditions of ultrasonic frequency 100KHz, output power 500W, and temperature 250°C, ultrasonically cracked for 5 hours, washed the lysate with 15 kg of 3% liquid alkali aqueous solution, left standing for oil-water separation, and the separated oil phase was fractionated by a fractionating tower, collected Distillate between 80~260 DEG C; dehydration by water separator (0.35% by mass of water in the distillate), obtain 80 kilograms of distillate, add 0.81 kilogram of antioxidant butyl hydroxyanisole in distillate and dissolve evenly, prepare to obtain plant source Green environmental protection solvent.

[0037] The composition of the detected plant source green solvent is 31% by mass of pinene, 29% by mass of D-limonene, 7% by mass of longifolene, 12% by mass of ca...

Embodiment 3

[0039] Take by weighing 100 kilograms of masson pine turpentine, add in the fat storage pool after pulverizing, remove moisture; The turpentine after dehydration is mixed with 0.5 kilogram of H4[SiMo12O40]xH2O molybdosilicic acid (x is 1-12) catalyst mixes; Under the conditions of ultrasonic frequency 50KHz, output power 500W, and temperature 250°C, ultrasonic cracking was performed for 5 hours, the lysate was washed with 8 kg of 6% liquid alkali aqueous solution, and the oil and water were left to separate. The separated oil phase was fractionated by a fractionating tower and collected Distillate between 80~260 ℃; dehydration by water separator (0.35% by mass of water in the distillate), obtain distillate 78 kilograms, add 0.79 kilograms of antioxidant butyl hydroxyanisole in distillate and dissolve evenly, prepare to obtain plant source Green environmental protection solvent.

[0040] The composition of the detected plant source green solvent is pinene containing 28% by mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com