Treatment method for pine wood for furniture

A treatment method, pine wood technology, applied in wood treatment, pressurized wood treatment, wood treatment details, etc., can solve the problems of unsatisfactory effect, incomplete degreasing, long degreasing time, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

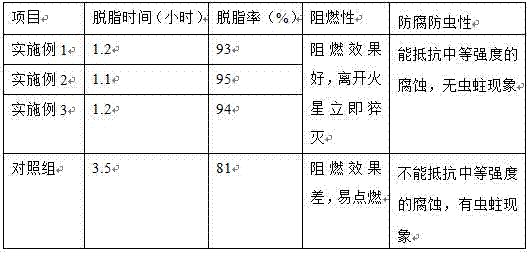

Examples

Embodiment 1

[0014] A method for processing pine wood for furniture, comprising the following steps:

[0015] (1) Saw the newly felled pine wood into the required size, put it into the clear water pool for soaking, and add 1.5% oil-removing and whitening agent in the clear water pool. The preparation is made of the following ingredients in terms of mass percentage Composition: AEO accounts for 30%, ethanol accounts for 8%, LAS accounts for 6.5%, sodium carbonate accounts for 4.5%, triethanolamine accounts for 3.5%, sodium xylene sulfonate accounts for 0.8%, optical brightener accounts for 0.02%, and the rest is water. Soak until the water content reaches 80%, heat and cook for 3 minutes, and then de-dry at 60°C until the water content is 30%;

[0016] (2) Put the de-dried pine board into the hot press, gradually raise the temperature to 120°C within 8 minutes, and carry out heat preservation treatment for different lengths of time according to the thickness of the wood. The linear relation...

Embodiment 2

[0021] A method for processing pine wood for furniture, comprising the following steps:

[0022] (1) Sawn the newly felled pine into the required size, put it into the clear water pool for soaking, and add a degreasing and whitening agent with a mass fraction of 1.7% in the clear water pool. The preparation is made of the following ingredients in terms of mass percentage Composition: AEO accounts for 31%, ethanol accounts for 9%, LAS accounts for 6.8%, sodium carbonate accounts for 5.0%, triethanolamine accounts for 4.0%, sodium xylene sulfonate accounts for 0.9%, optical brightener accounts for 0.03%, and the rest is water. Soak until the water content reaches 85%, heat and cook for 4 minutes, and then de-dry at 65°C until the water content is 32%;

[0023] (2) Put the de-dried pine board into the hot press, gradually raise the temperature to 125°C within 9 minutes, and carry out heat preservation treatment for different lengths of time according to the thickness of the wood....

Embodiment 3

[0028] A method for processing pine wood for furniture, comprising the following steps:

[0029] (1) Sawn the newly felled pine into the required size, put it into the clear water pool for soaking, and add 2.0% of oil-removing and whitening agent in the clear water pool. The preparation is made of the following ingredients in terms of mass percentage Composition: AEO accounts for 32%, ethanol accounts for 10%, LAS accounts for 7.0%, sodium carbonate accounts for 5.5%, triethanolamine accounts for 4.5%, sodium xylene sulfonate accounts for 1.0%, optical brightener accounts for 0.04%, and the rest is water. Soak until the water content reaches 90%, heat and cook for 5 minutes, and then de-dry at 70°C until the water content is 35%;

[0030](2) Put the de-dried pine board into the hot press, gradually raise the temperature to 130°C within 10 minutes, and carry out heat preservation treatment for different lengths of time according to the thickness of the wood. The linear relation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com