Deoiling apparatus for cooling waste gas of TRT bearing box

A technology of deoiling device and bearing box, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of lubricating oil waste, environmental pollution, etc., and achieve improved deoiling effect, good cooling and adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention is described in detail below with specific embodiments:

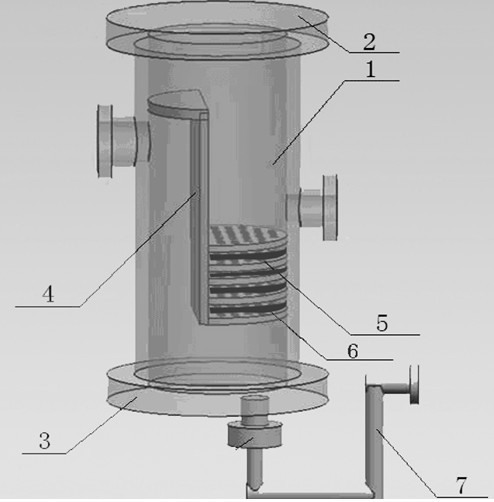

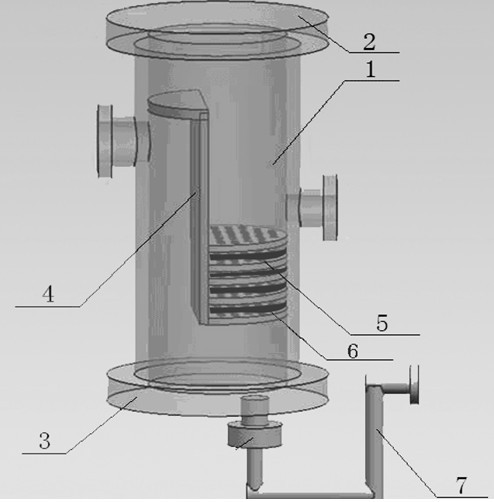

[0021] Such as figure 1 As shown, a deoiling device for cooling exhaust gas of a TRT bearing box includes a tank body 1, an air inlet and an exhaust port are arranged on the tank body 1, and an oil baffle plate is arranged on the inlet direction of the air inlet in the tank body 1 4. Along the gas flow direction, there is an oil removal plate 5 at the front of the exhaust pipe; the upper and lower ends of the tank body 1 are equipped with an upper flange 2 and a lower flange 3 for maintenance.

[0022] The bottom of the tank body is provided with an oil discharge pipe, and the oil discharge pipe adopts the structure of a U-shaped pipe 7, and the other end of the U-shaped pipe 7 communicates with the fuel tank.

[0023] The oil baffle plate 4 in the air intake direction is perpendicular to the air inlet and is at a distance from the bottom end of the tank body. The upper end and both sides of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com