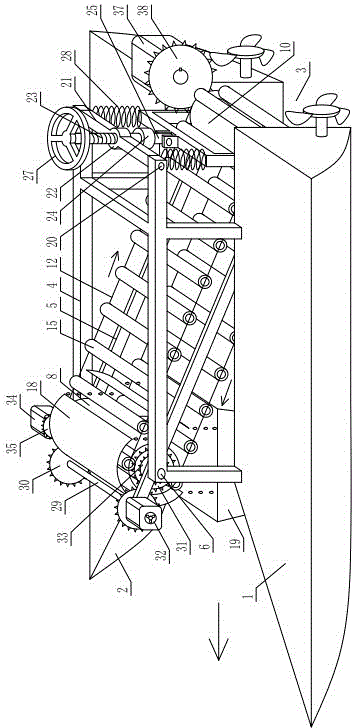

This kind of centrifugal oil suction vessel has the functions of automatic oil suction and oil rejection (oil collection), which saves manpower, but has the following obvious shortcomings: 1. The

conveyor belt only relies on its own oil-friendly and non-hydrophilic characteristics and the ability to press

oil pollution into the bottom Oil is sucked under

high pressure, but it cannot be completely and completely absorbed. After the centrifugal oil suction ship passes, a large amount of oil will still be left on the water surface to form "oil leakage"; Very high, that is, the speed of the

conveyor belt is very high, which not only reduces the

oil absorption effect, forms a large amount of "oil leakage", but also requires a high-power engine, which will inevitably result in high costs; It is a

ray tangent to the

conveyor belt at the turning point, and these rays are

ray clusters that slope upwards from the horizontal plane around the turning point of the conveyor belt, and the trajectory of the oil that can be thrown into the oil collection tank is only a pole of the above-mentioned trajectory

ray clusters. A small part, therefore, the

oil pollution is not only thrown upwards into the oil collection tank, but more

oil pollution is thrown backwards to the water surface behind the ship to form a large amount of "leaked oil", that is to say, the centrifugal oil

pollution cleaning ship The

oil absorption effect is average

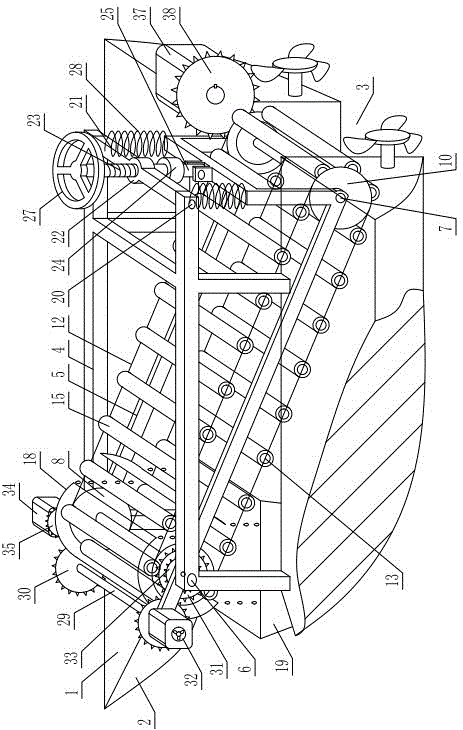

However, the ship has the following disadvantages: 1. Because the oil-absorbing roller relies on its own rolling to press the oil into the natural contact of the water to absorb oil, the oil-absorbing roller cannot guarantee that all the encountered oil will be absorbed, and the oil is not completely absorbed. There are many "oil leaks", and the oil

absorption effect and efficiency are poor; 2. When the scraper scrapes the oil-absorbing roller, the oil on the side (outside) of the oil-absorbing roller adjacent to the scraper will flow into the oil flow groove along the scraper, but the other side of the oil-absorbing roller The oil squeezed out from the side (inner side) will flow along the inner wall of the oil suction roller and cannot be scraped off by the scraper, thus forming "oil reservoir" or "bottom oil". The oil

absorption effect of the

stroke, and this part of the "oil reservoir" may flow out along the two ends of the inner cavity of the oil absorption roller to form "oil leakage"; 3. In this patent, the oil scraped in the oil flow

ditch flows out of the oil by its own gravity groove, but because the oil is viscous, the oil scraped by the scraper will adhere to the inner wall of the oil flow groove after entering the oil flow groove; because the conveyor belt where the oil flow groove is located is rotating in a cycle, it is not equal to the inside of the oil flow groove The oil will be sent to the oil suction roller by the conveyor belt to scrape the oil again. Obviously, the scraping effect of the scraper will become worse and worse, and even the oil accumulated in the oil flow channel will be squeezed onto the oil suction roller. Scraping the oil-absorbing roller becomes oiling the oil-absorbing roller; 4. As can be seen from the drawings, the scrapers are arranged at intervals on the conveyor belt, so there will be two situations. 1. If the rotation speed of the scraper or the conveyor belt is slow, only The oil in the oil-absorbing roller corresponding to the scraper can be scraped off, but the oil in the oil-absorbing roller corresponding to the conveyor belt between two adjacent scrapers cannot be scraped off, which forms a

blind spot for scraping oil, which will turn to the On the surface of the water, not only does it not absorb oil, but it may also flow the absorbed oil into the water, greatly reducing the oil

absorption efficiency and effect. Second, if the speed of the scraper and the conveyor belt is much higher than the speed of the oil suction roller, the fast alternate scraper can eliminate the above blind spots, but in this way Not only will it increase the

wear and tear of the scraper on the oil-absorbing roller, but also the oil in the oil-flowing

ditch will be scratched against the oil-absorbing roller again without time to flow out, which will also cause the disadvantages of oil delivery like the oil-absorbing roller; 5. In order to achieve better The oil scraping effect will inevitably increase the

extrusion force between the scraper and the oil-absorbing roller, which will inevitably increase the scraping and wear of the scraper on the oil-absorbing roller, and the oil-absorbing roller needs to be replaced frequently, which is not only troublesome to maintain, but also inevitably increases the cost

[0006] The above two patents also have a common shortcoming, that is, there is no function of adjusting the height of the oil-absorbing roller or the conveying belt, so that as the oil-absorbing continues, the total weight of the

hull will inevitably increase, and more parts of the oil-absorbing roller or conveying belt will be immersed in water. , so that the oil absorption roller or conveyor belt cannot be in the best oil absorption state, and the working state is unstable, that is to say, the oil

absorption effect will become worse and worse

Login to View More

Login to View More  Login to View More

Login to View More