Patents

Literature

34results about How to "Absorb clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

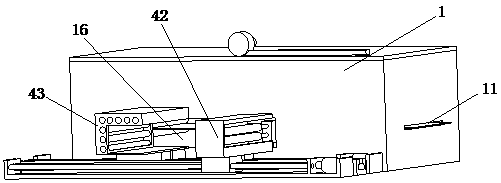

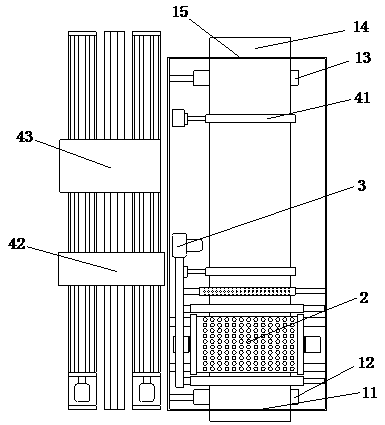

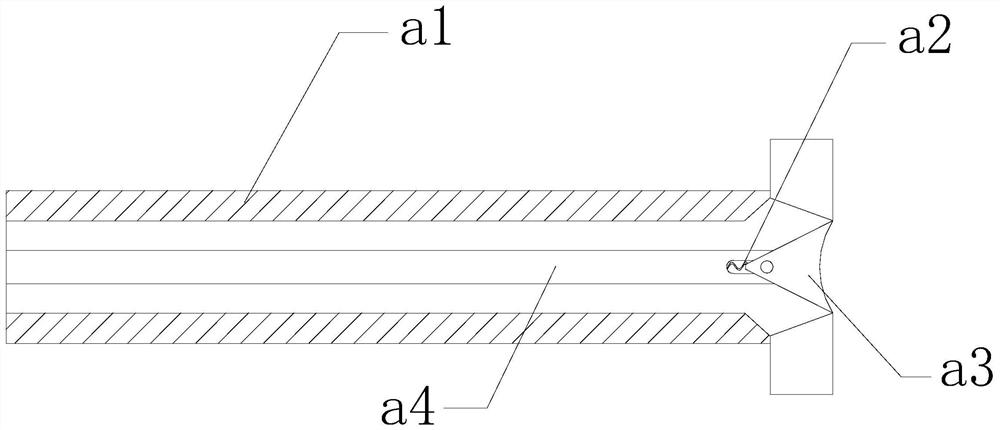

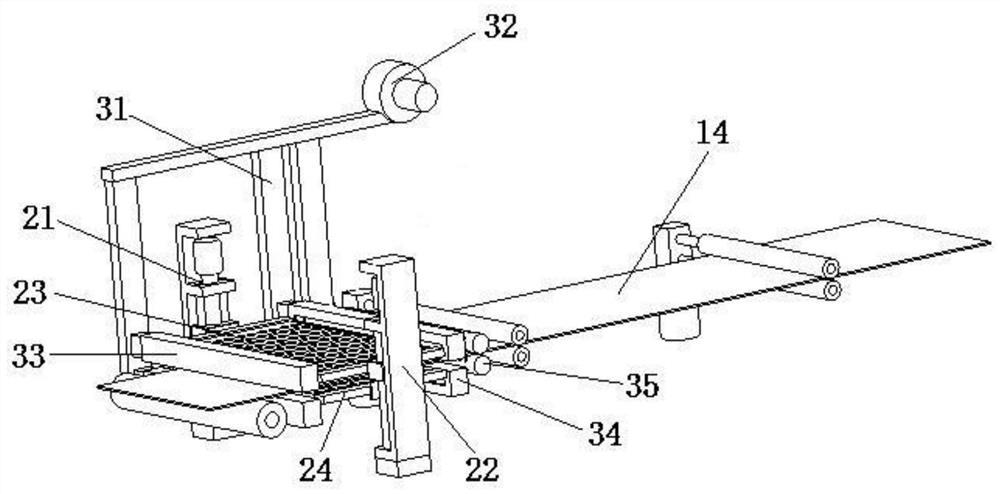

Wheel type paper cutting machine with follow-up tiny paper scrap adsorbing device

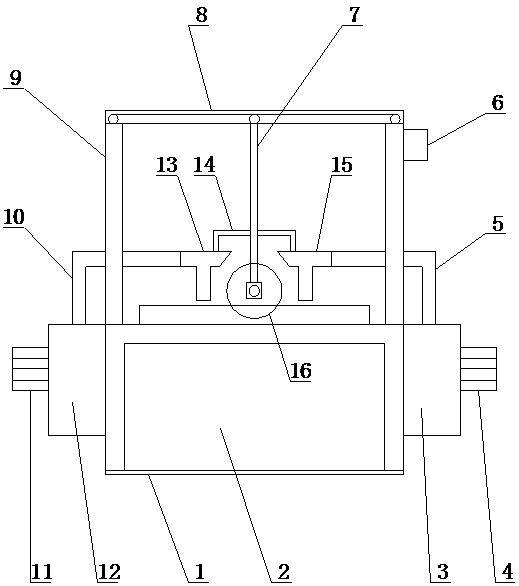

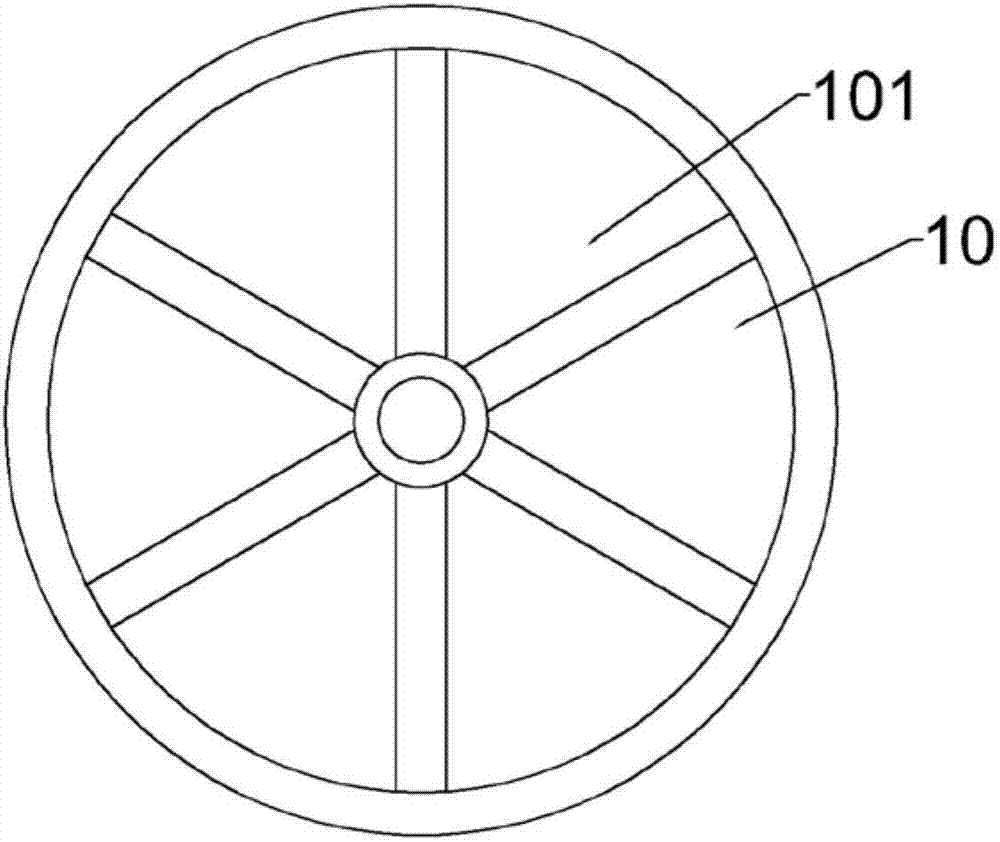

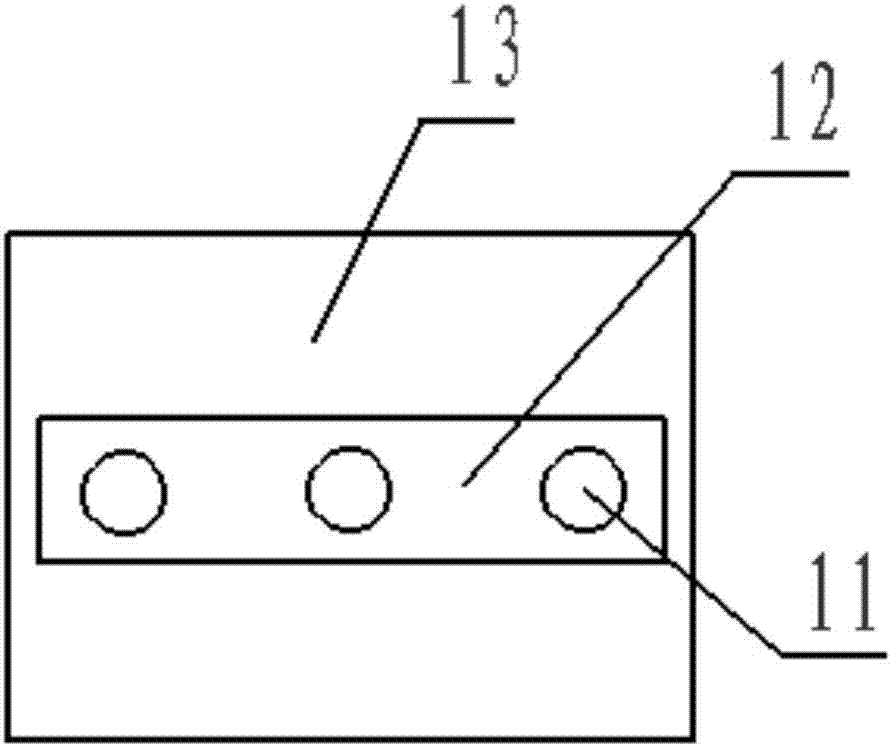

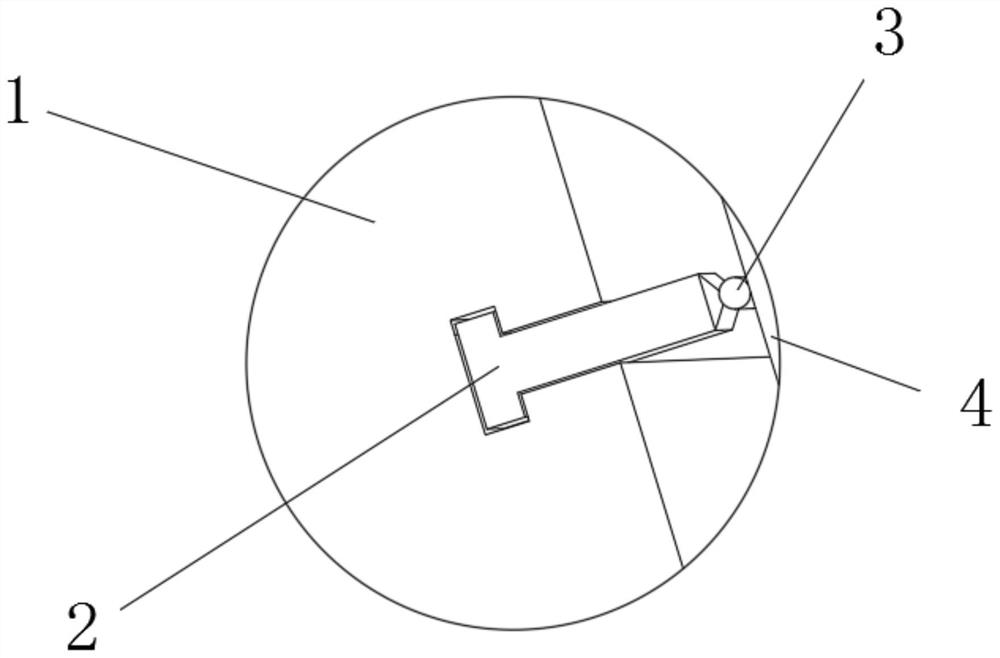

The invention relates to the field of paper cutting equipment, in particular to a wheel type paper cutting machine with a follow-up tiny paper scrap adsorbing device. The wheel type paper cutting machine with the follow-up tiny paper scrap adsorbing device comprises a support arranged on a working table top, wherein a sliding rail is arranged on the upper portion of the support, a sliding wheel is arranged in the sliding rail, the sliding wheel is arranged on a belt in a sleeved mode, and the belt is driven by a motor arranged on the upper portion of the right side of the support. The sliding wheel is connected with a connecting rod, the upper end of the connecting rod is a U-type end, the connecting rod is connected to convex shafts on the two sides of the sliding wheel through the U-type end, a cutter motor is connected to the bottom of the connecting rod, and a wheel-type cutting blade is arranged on the spindle head of the cutter motor in a sleeved mode. A lower frame is arranged on the middle portion of the connecting rod, and the two ends of the lower frame are connected with a left adsorbing head and a right adsorbing heat respectively. The wheel type paper cutting machine with the follow-up tiny paper scrap adsorbing device can move along with the moving of the wheel-type cutter blade, cleanly adsorbs the paper scrap dust raised by the wheel-type cutter blade, also cleanly adsorbs the paper scrap dust on paper on the working table top, protects the environment of a workshop, and also ensures the physical health of operating personnel.

Owner:TAICANG XINHE PRINTING & PACKAGING

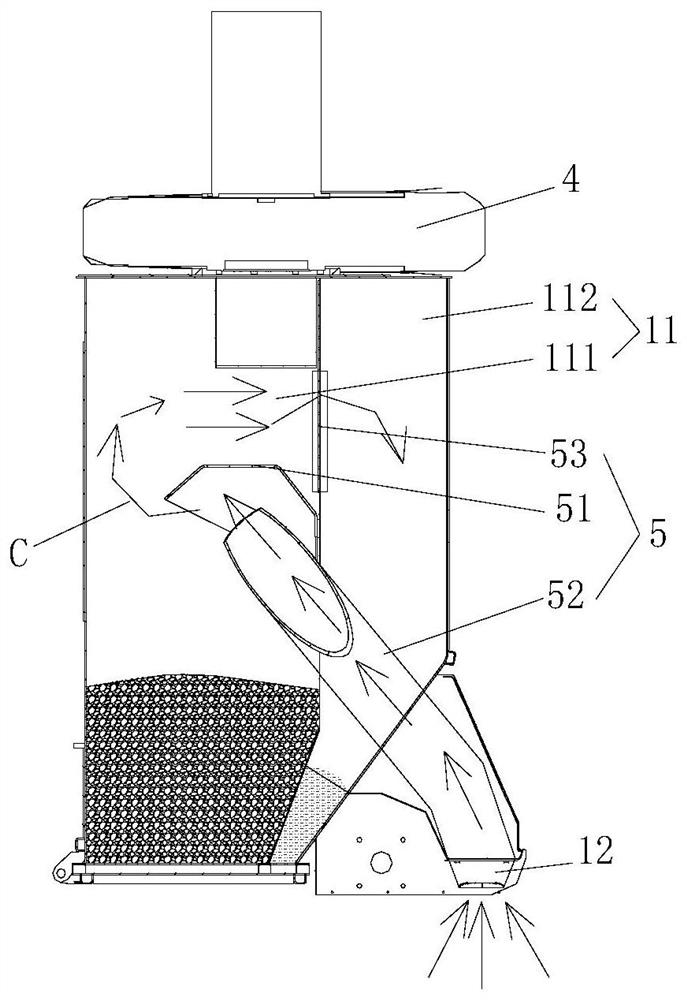

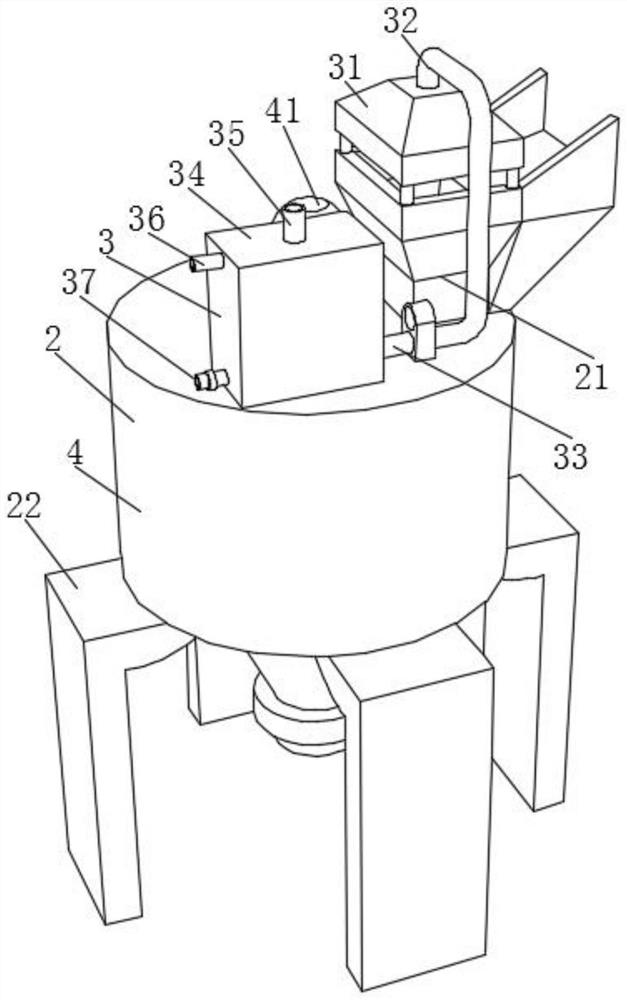

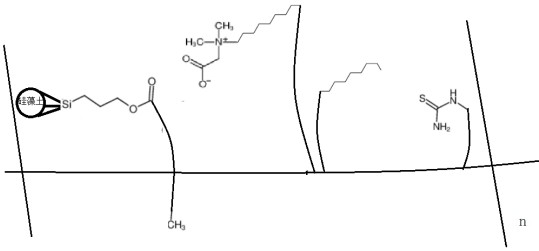

Dust absorbing and treating device for building site

InactiveCN107497233AAbsorb cleanReduce dust contentCombination devicesDirt cleaningEngineeringMechanical engineering

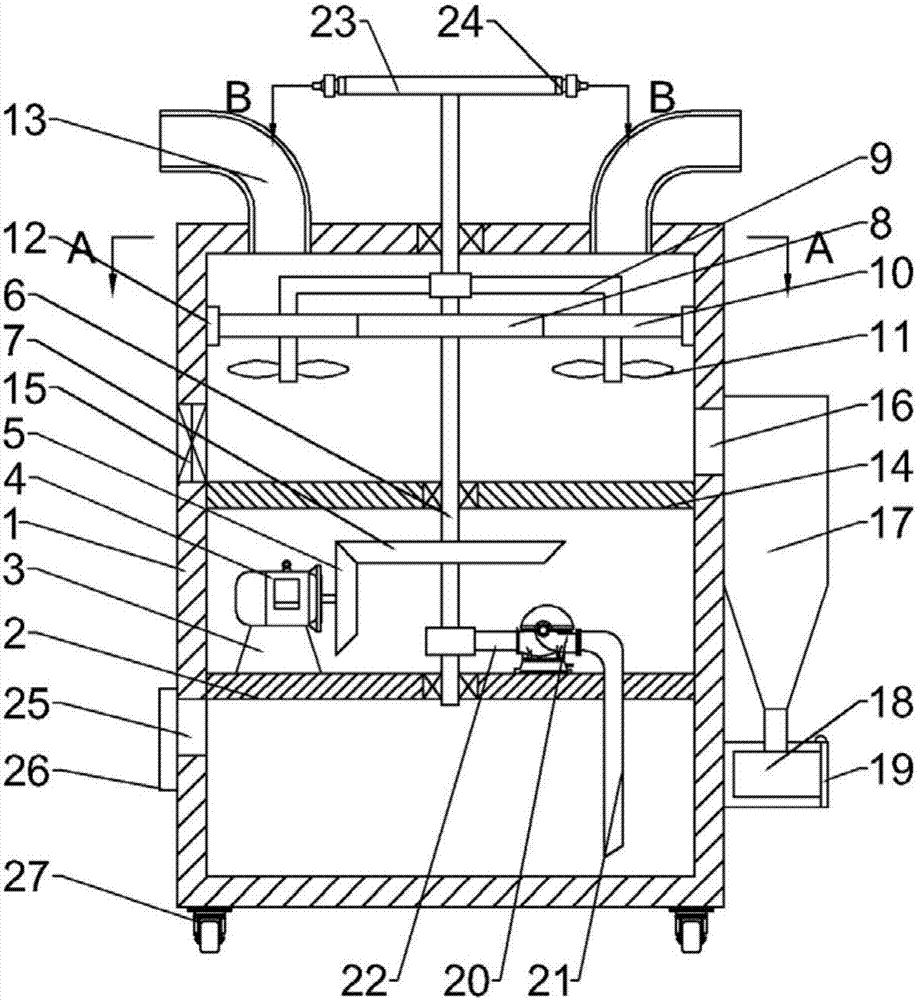

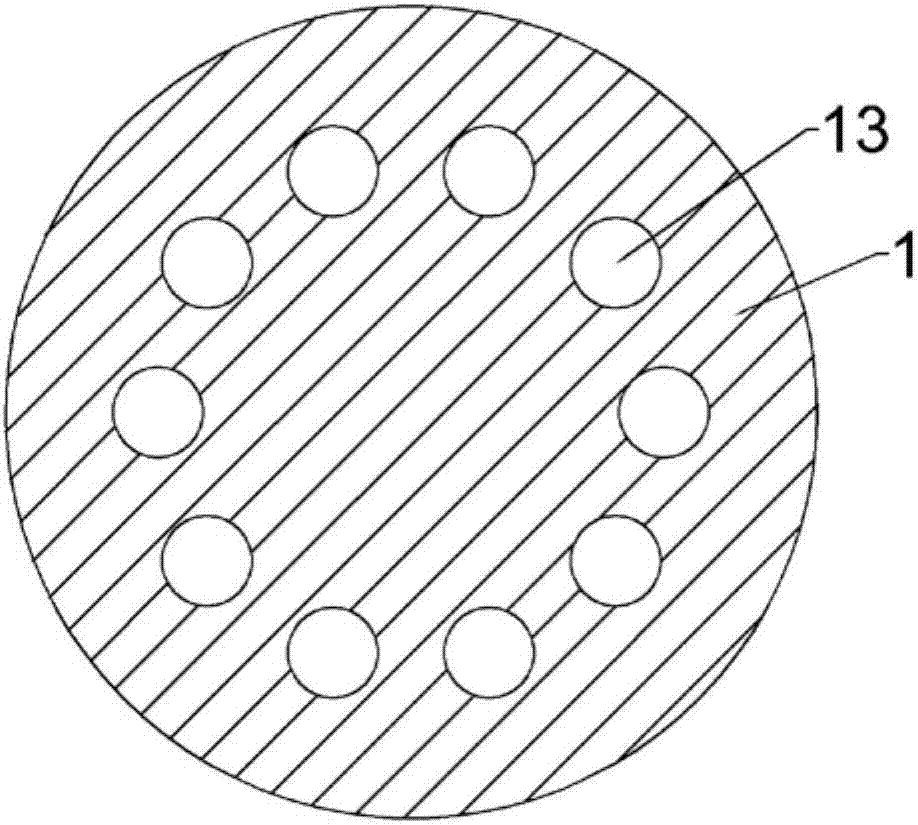

The invention discloses a dust absorbing and treating device for a building site. The dust absorbing and treating device comprises a shell, a lower partition is fixedly connected below the inside of the shell, a motor seat is fixedly connected on the left side above the lower partition, a motor is fixedly connected above the motor seat, an output end of the motor is fixedly connected with a driving bevel gear, a longitudinal rotating shaft is rotatably connected in the middle above the lower partition through bearing and is of a tubular structure, a driven bevel gear is fixedly connected below the longitudinal rotating shaft, and the driven bevel gear and the driving bevel gear are meshed. Compared with the prior art, the dust absorbing and treating device has the advantages that the device is simple in structure and convenient to use; through omnibearing dust absorbing, dust in each direction of the device can be absorbed more cleanly; the device combines two modes of dust collection for convenience of treatment with water spraying to lower dust content in air, so that environment of the building site is better, and the device is worthy of popularization.

Owner:陆春土

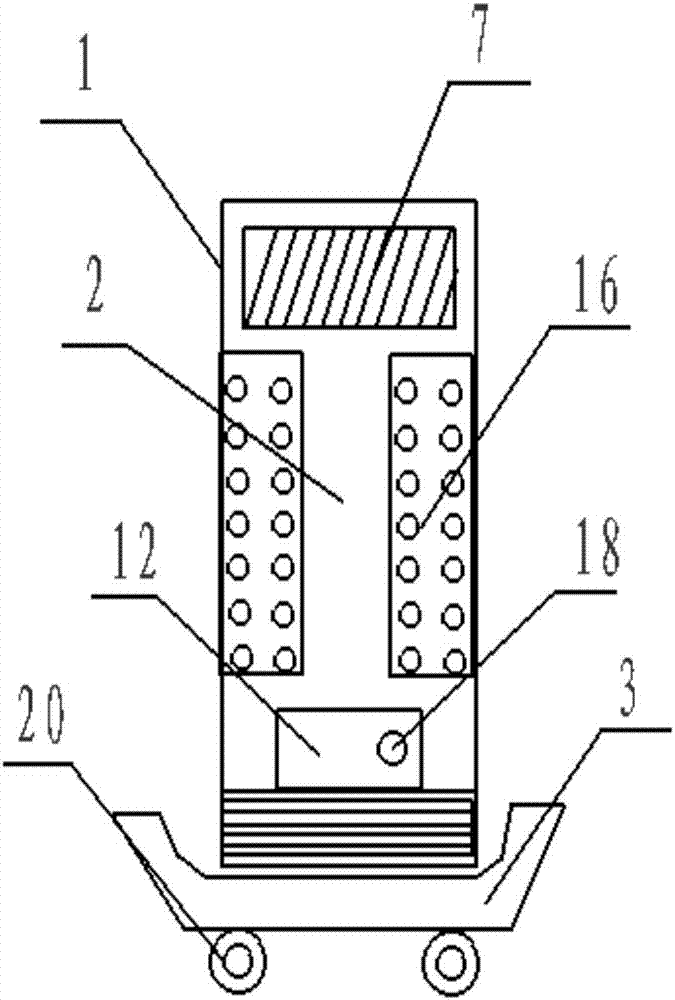

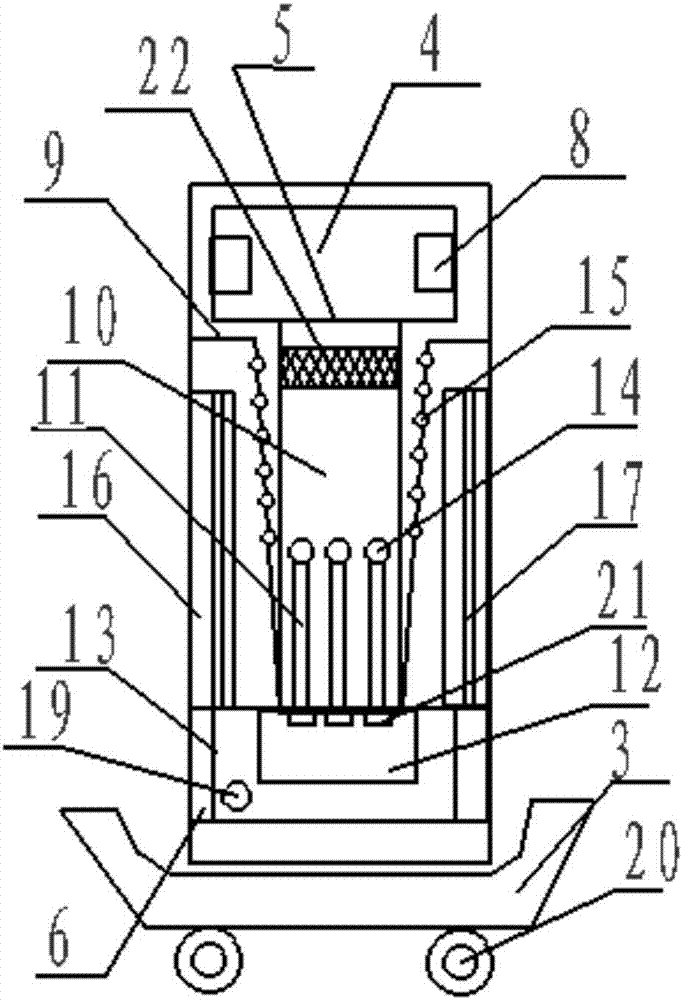

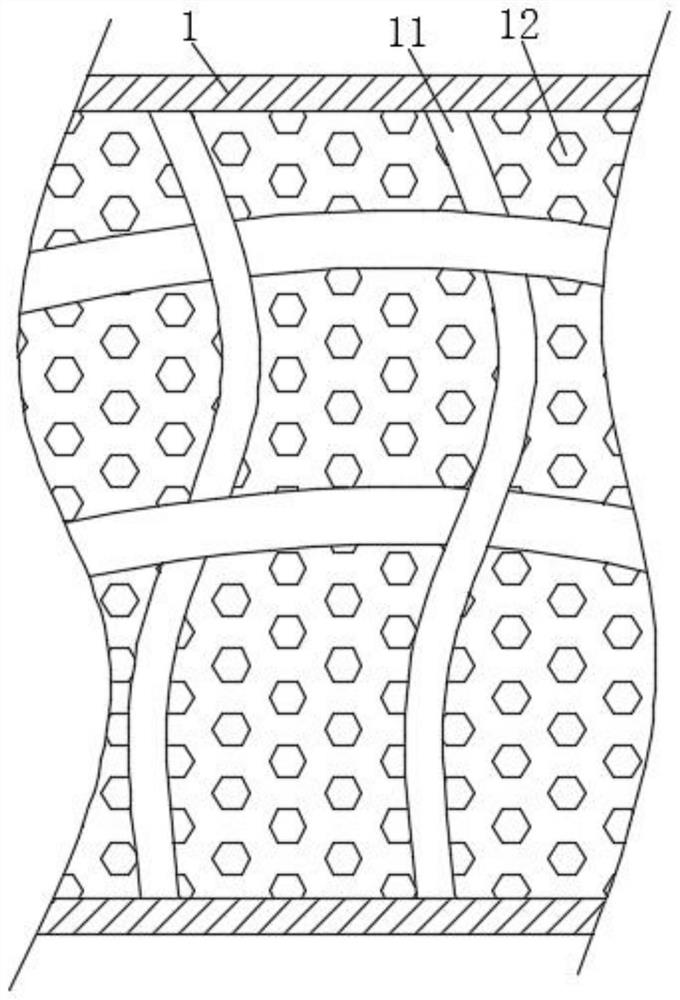

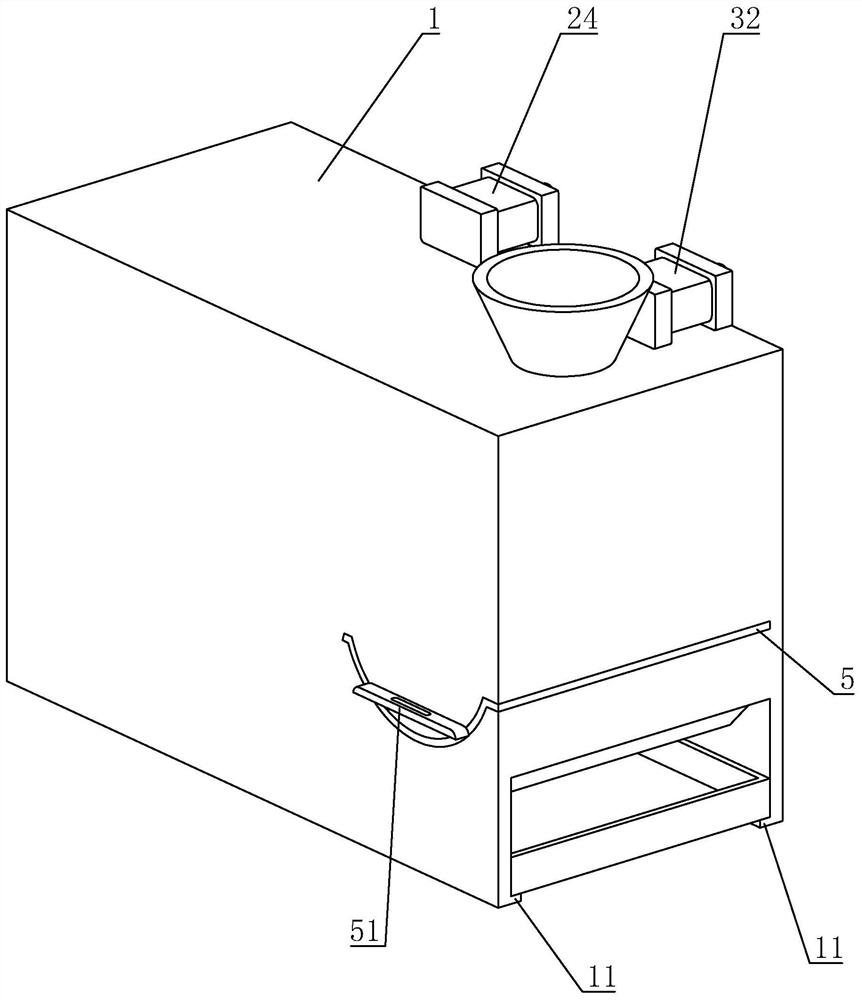

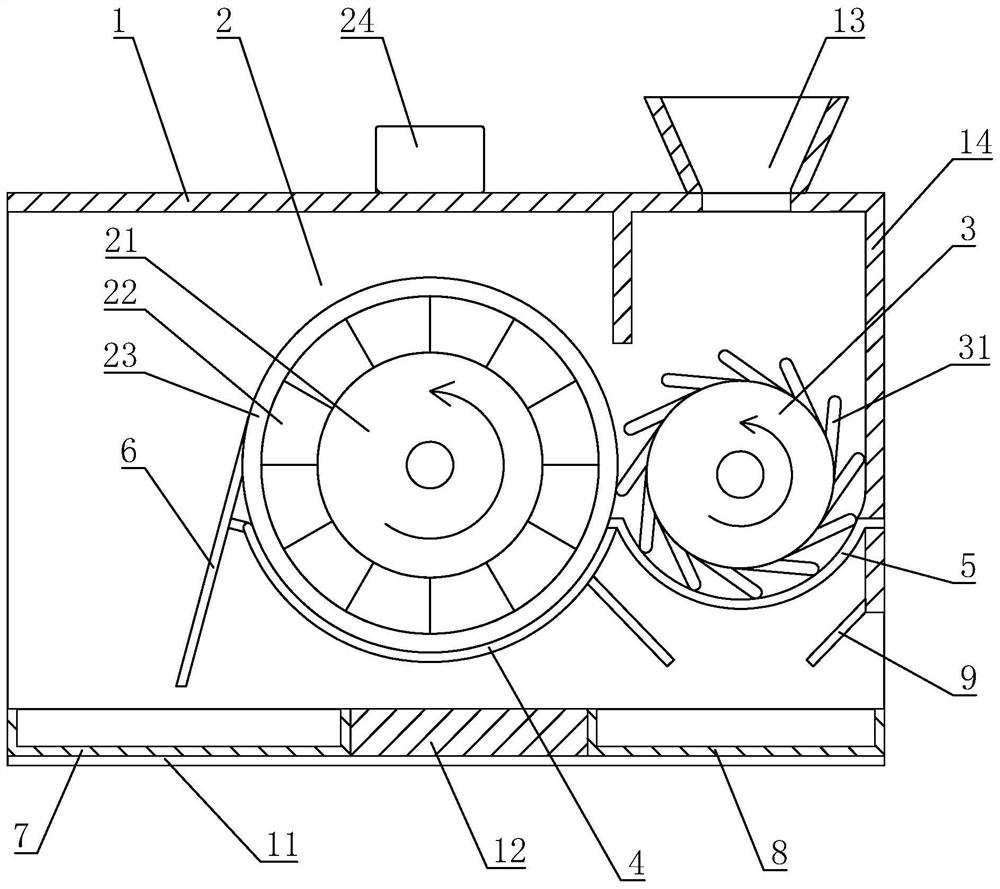

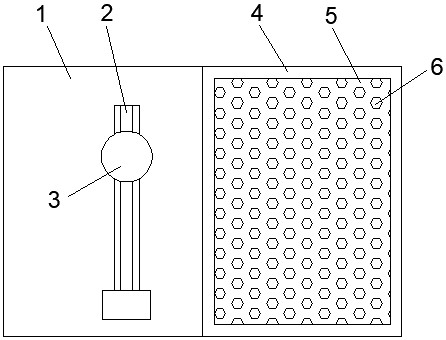

Dust removal equipment for cloth printing and dyeing process

ActiveCN110125098AAvoid pollutionAbsorb cleanMechanical cleaningPressure cleaningEngineeringContamination

The invention discloses dust removal equipment for a cloth printing and dyeing process. The dust removal equipment comprises a shell, a patting part, a dust collection part and a dust removal part; the patting part is positioned in the shell, the dust collection part is positioned in the shell, and the dust removal part is located outside the shell; the dust removal part comprises a dust removal assembly, a cleaning assembly and a drying assembly, the dust removal assembly is located in the shell, the cleaning assembly is located outside the shell, and the drying assembly is located beside thecleaning assembly; the patting part, the dust collection part and the dust removal assembly on the dust removal part are located in the shell, the shell can provide protection for a whole dust removal working environment, the whole dust removal working environment is prevented from being affected by outside dust, and secondary contamination to cloth caused by dust in the dust removal process is prevented. According to the dust removal equipment for the cloth printing and dyeing process, the patting part is used for patting the cloth, and then dust collection is carried out on the patted cloththrough the dust collection part, a roller is cleaned through the cleaning assembly and the drying assembly under the condition that the dust removal equipment is still working, and the dust removalefficiency is improved.

Owner:绍兴金祥惠纺织印染有限公司

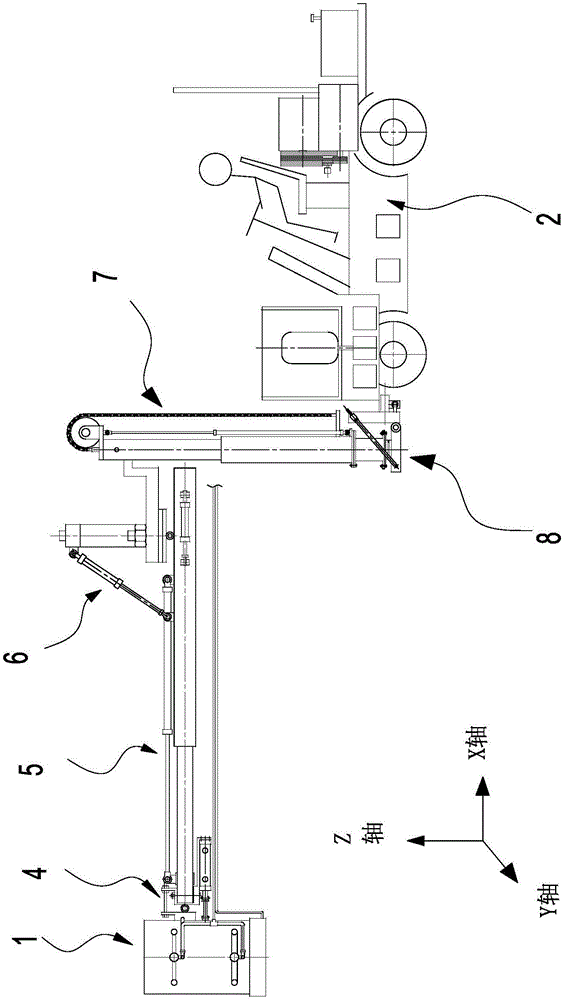

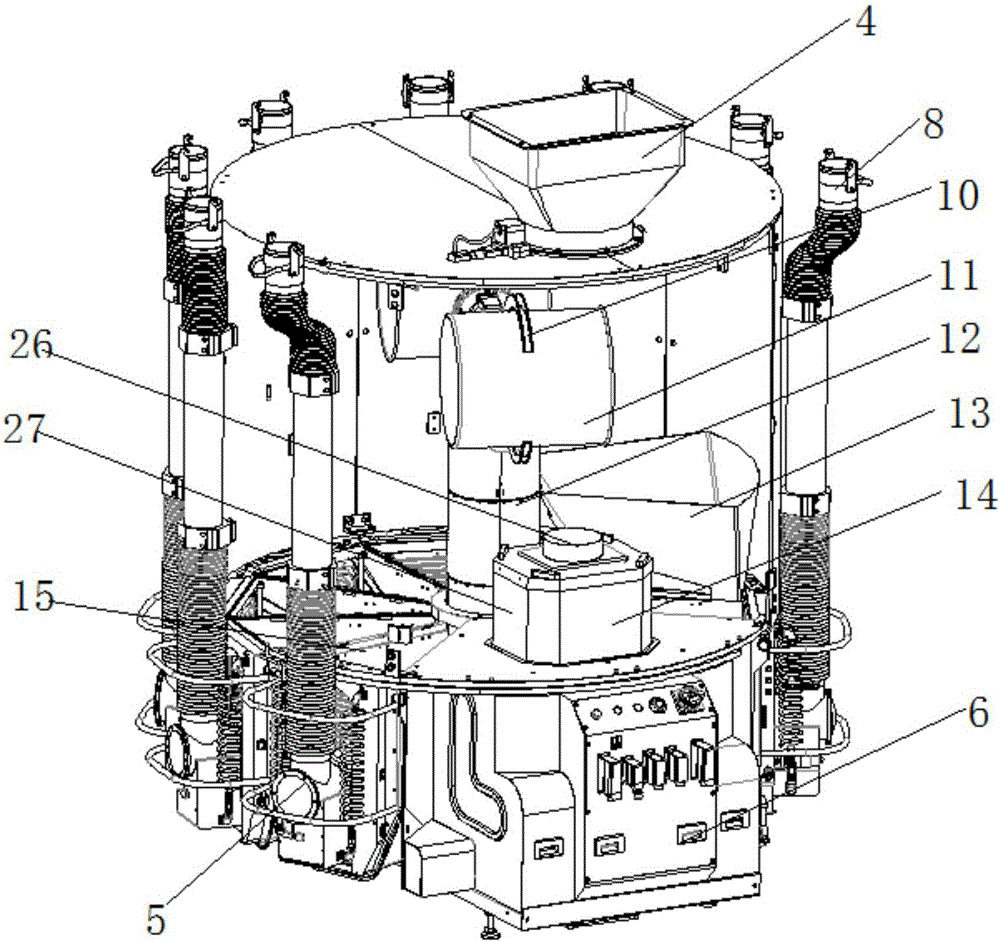

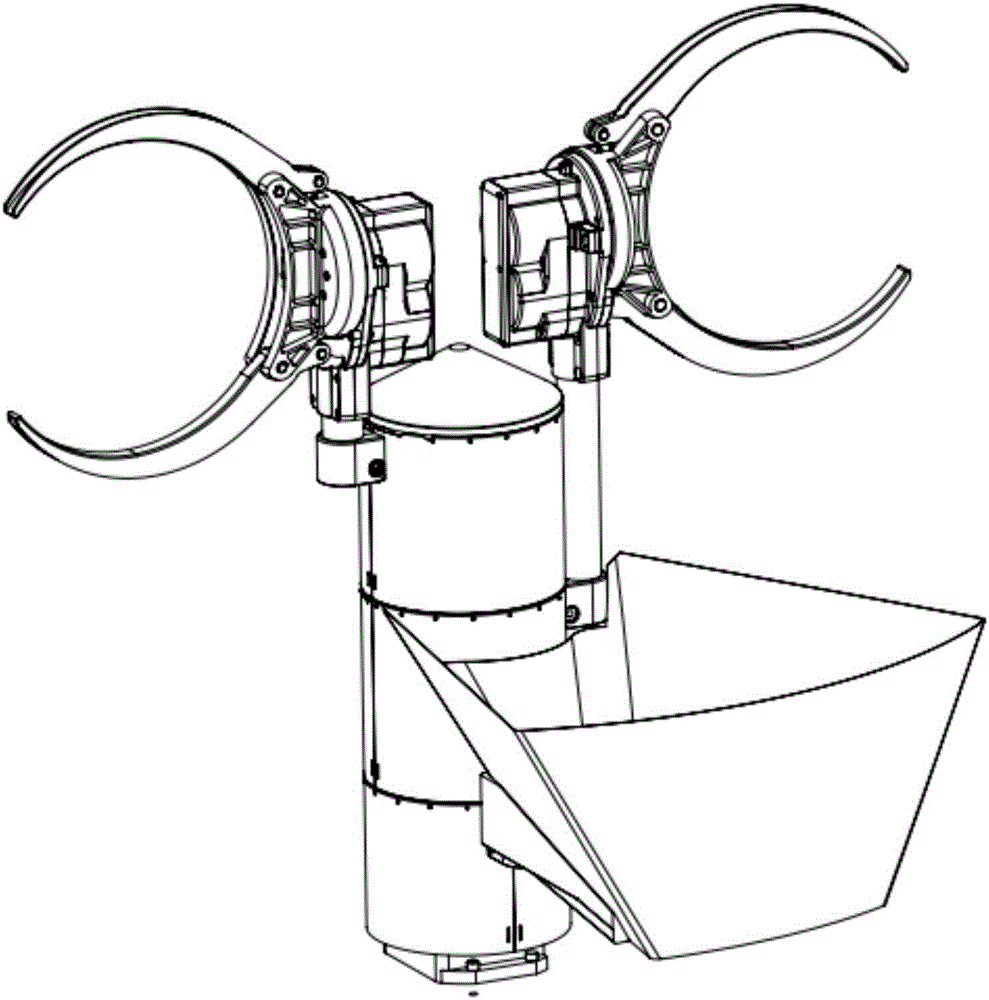

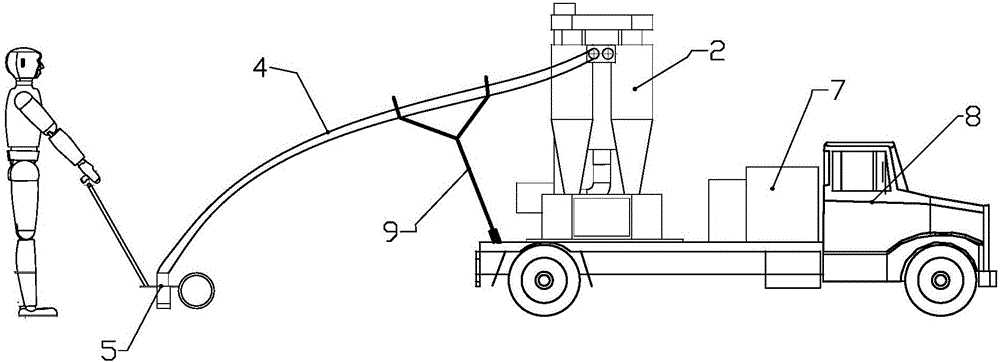

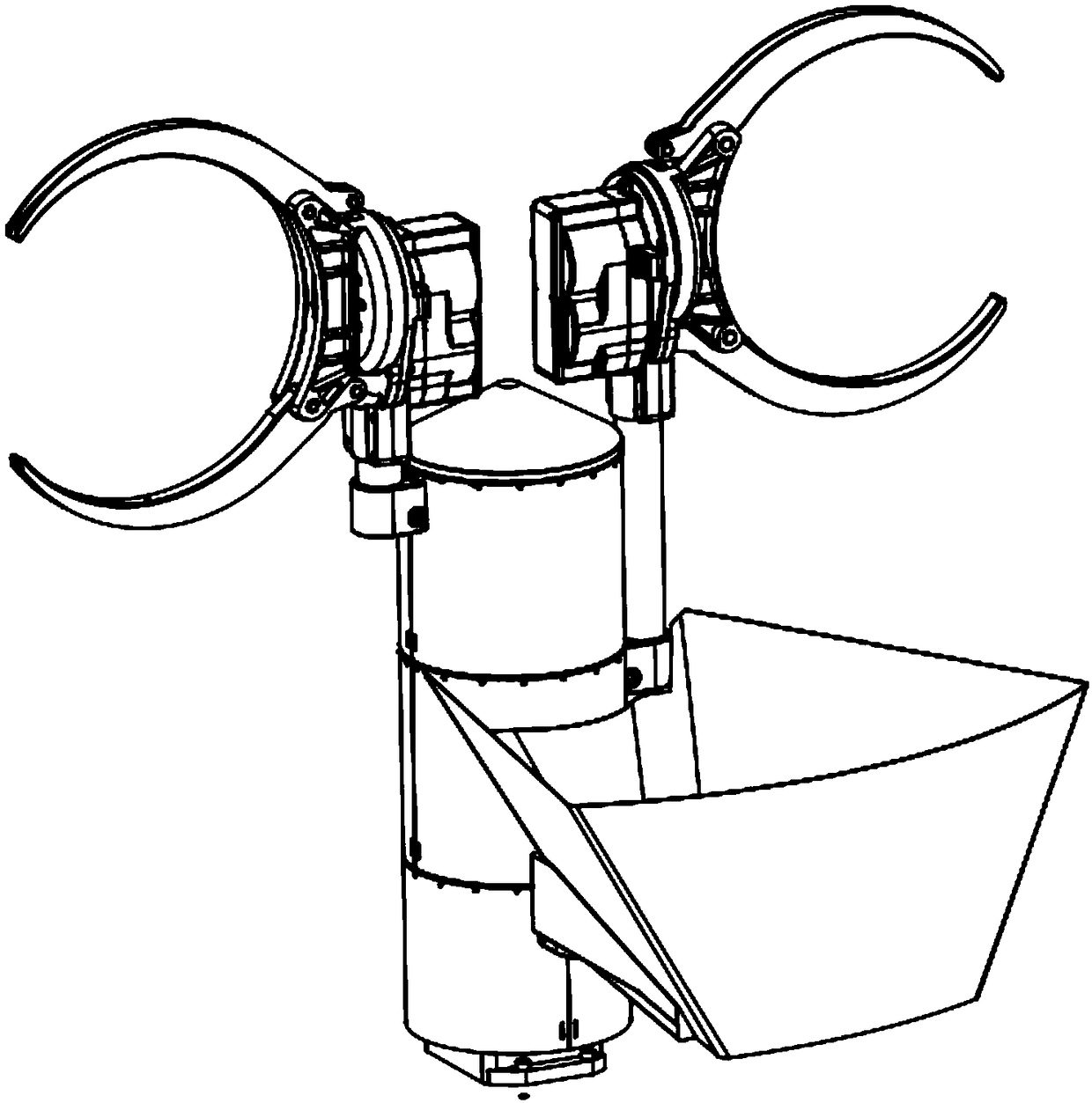

Trunk whitewashing machine

InactiveCN106670013AIncrease freedomAchieve any angleLiquid spraying apparatusPlant protectionLeft halfEngineering

The invention discloses a trunk whitewashing machine which comprises a motor vehicle. The motor vehicle is connected with a manipulator. A spray bucket assembly is connected to the front end of the manipulator. The spray bucket assembly comprises a left half bucket and a right half bucket which can be opened and closed. When the left half bucket and the right half bucket are closed, a trunk is clamped between the left half bucket and the right half bucket to be subjected to spraying. The manipulator comprises a lifting mechanism, a telescopic mechanism and a second connecting mechanism which is connected between the telescopic mechanism and the lifting mechanism. The lifting mechanism is connected with the motor vehicle through a first connecting mechanism. The telescopic mechanism is connected with the spray bucket assembly through a third connecting mechanism. The trunk whitewashing machine has the advantages that rotation in multiple directions can be achieved, the degree of freedom of rotation is high, and the application range of the trunk whitewashing machine is greatly broadened.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

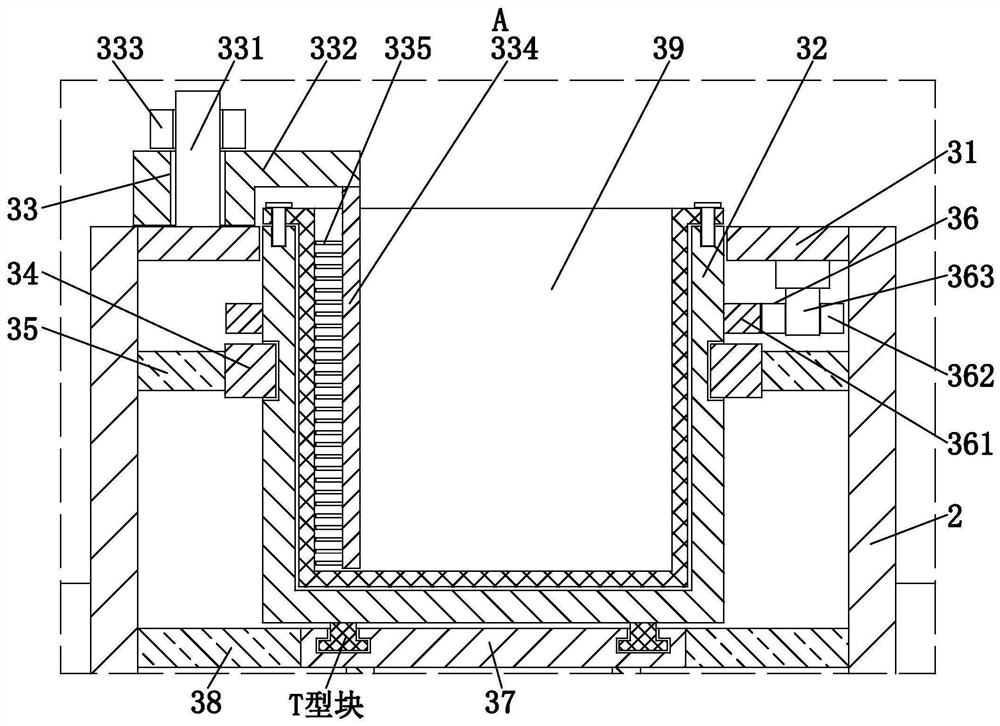

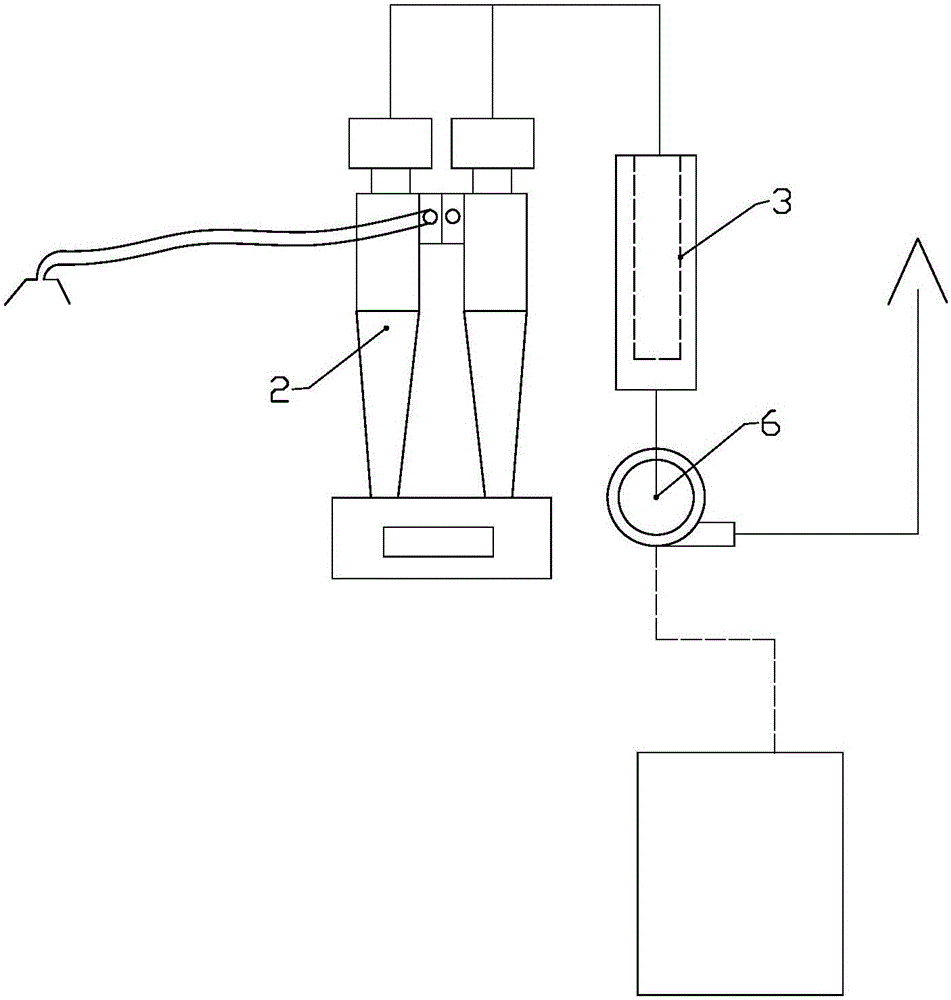

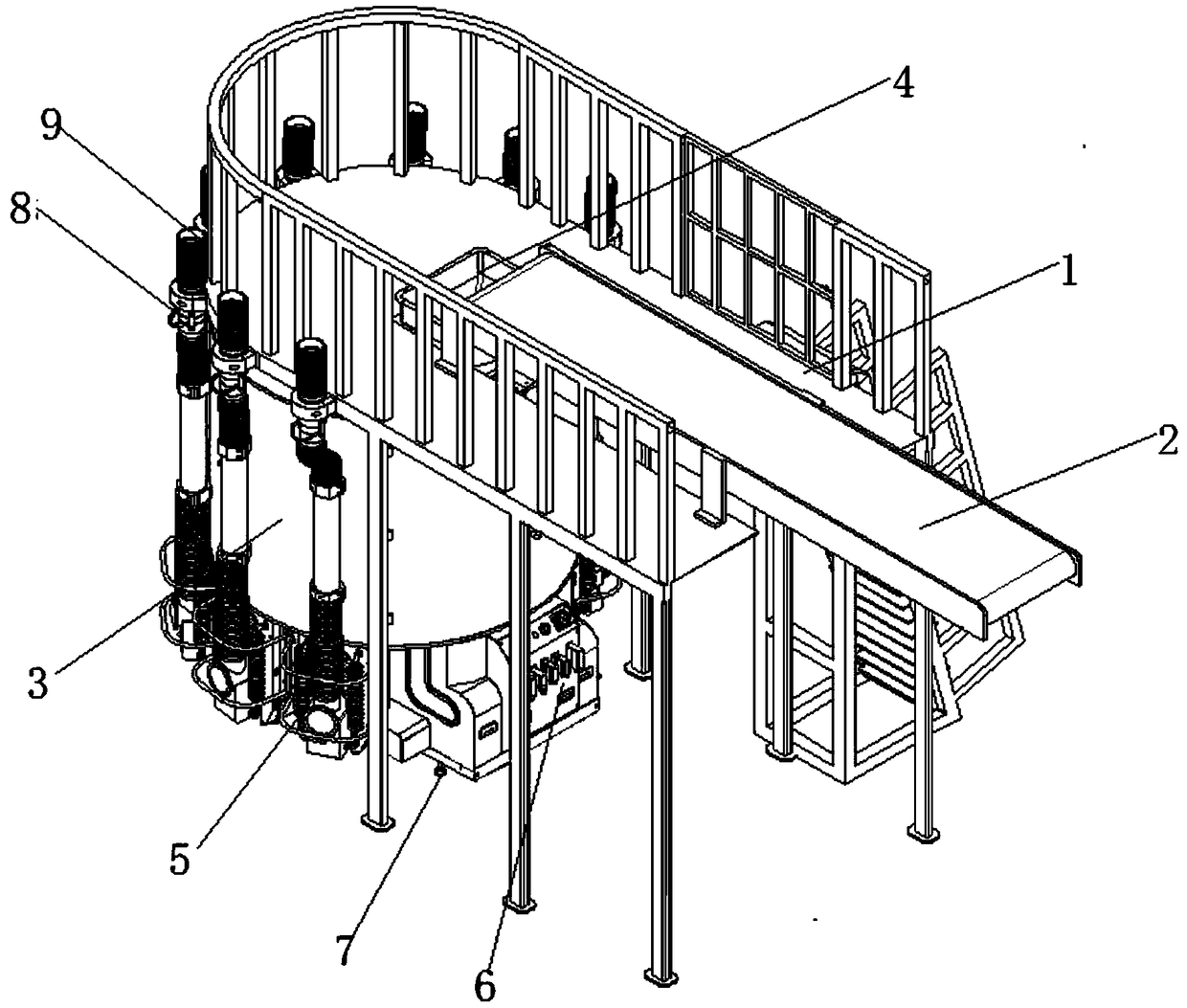

Construction site spray deduster

InactiveCN107243218AImprove hygieneImprove cleanlinessCombination devicesUsing liquid separation agentAgricultural engineeringInjector

The invention discloses a construction site spray deduster which comprises a spray deduster body, wherein the spray deduster body comprises a dedusting core and a movable pedestal; the dedusting core comprises an air-suction component, a filtering component and a pollution discharge component; the surface of the air-suction component forms a threaded connection with an air-suction net; the inner wall of the air-suction component forms a threaded connection with an air-suction device; a T-shaped groove is arranged in the filtering component; the middle part of the T-shaped groove is provided with a spray chamber; spray columns are arranged on the lower part of the spray chamber; a water tank is arranged under the spray columns; both sides of the water tank are provided with dust collection grooves; the top of each spray column forms a threaded connection with a spray injector; vent holes are arranged on the lateral sides of the T-shaped groove; and vent ports are arranged on the outer side of the dedusting core. The construction site spray deduster has the advantages of simple structure, low cost, long service life, favorable and uniform spray dedusting effects and high pollution discharge speed, and is convenient for cleaning; and by arranging universal rollers, the construction site spray deduster is convenient to move.

Owner:HUZHOU LUOFU TECH

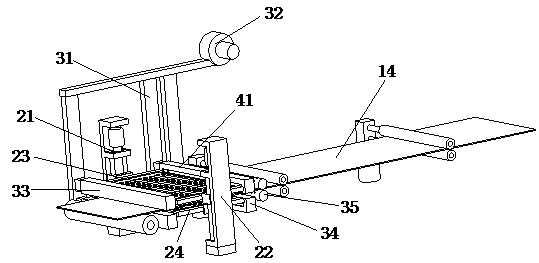

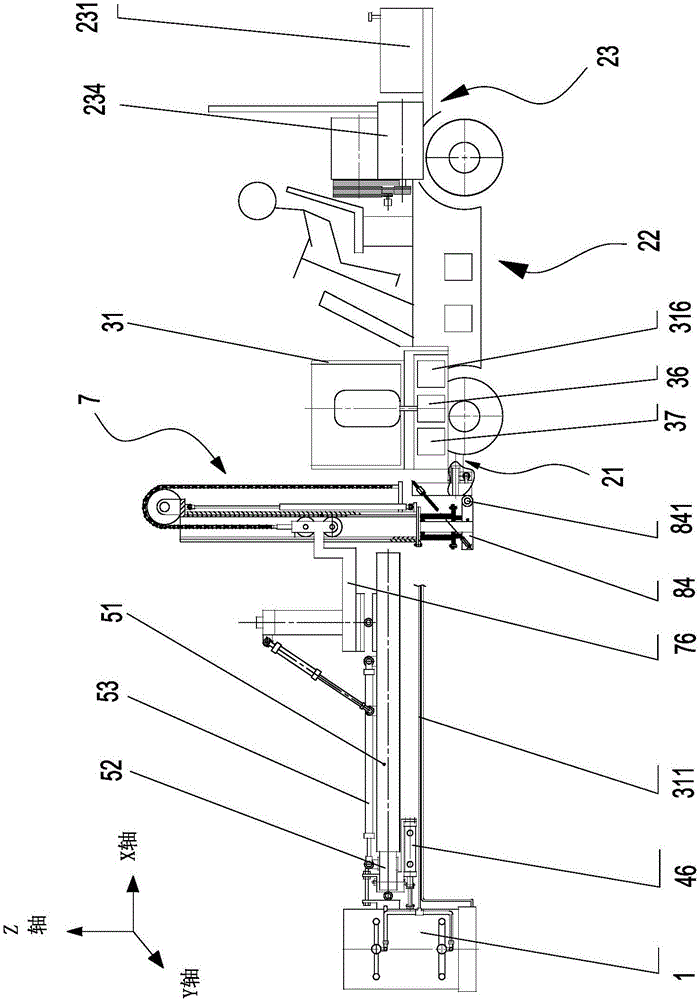

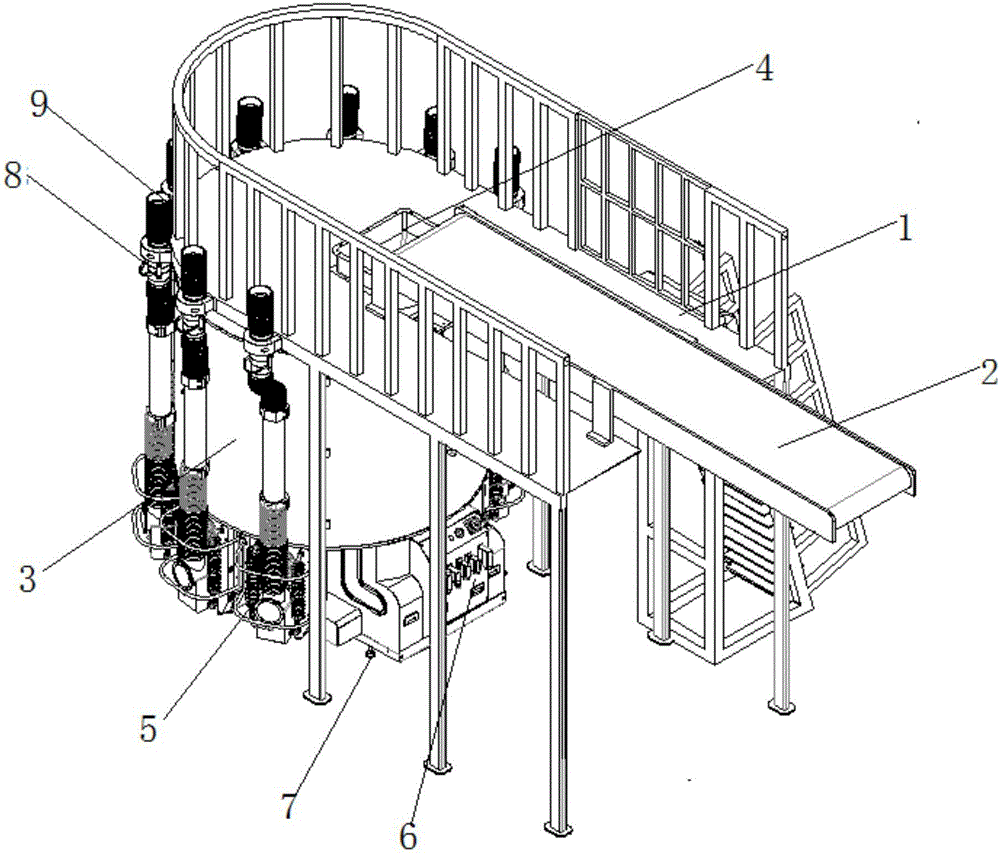

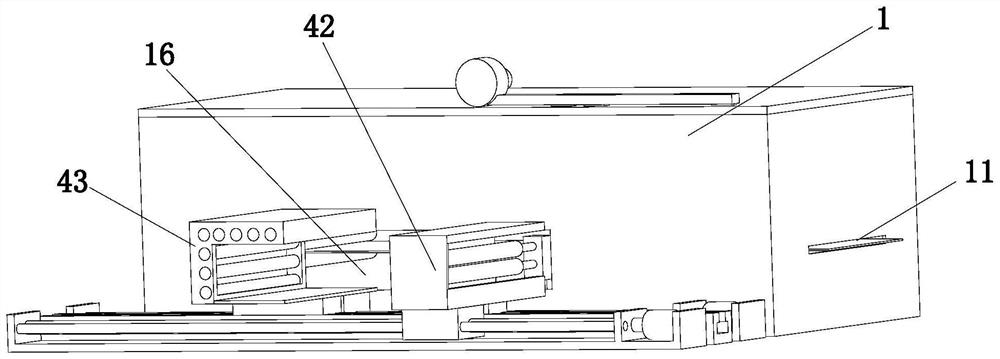

Novel shred feeding machine

The invention relates to a novel shred feeding machine which comprises a machine body, a shred absorbing device and a power supply device. The novel shred feeding machine is characterized in that a feeding port is formed on the machine body; a conveyer belt is arranged above the feeding port; the conveyer belt is fixedly arranged on a machine frame; the machine body is equipped with the power supply device and the shred absorbing device; a shred absorbing port is formed on the shred absorbing device; the shred absorbing device is connected with a shred absorbing pipe; a fast joint is arranged on the shred absorbing pipe; a discharging slot and a manipulator fixer are arranged in the machine body; a manipulator is arranged on the manipulator fixer; a charging barrel can be clamped by the manipulator; a weighting device is also arranged on the machine body; and the weighting device is used for weighting the charging barrel. The novel shred feeding machine disclosed by the invention has the beneficial effects that the tobacco shreds used by each cigarette making machine can be counted and recorded; the problem of material blocking of the shred feeding machine can be effectively prevented; when the shred feeding machine is in fault or is maintained, the shred feeding machine under a working state is wholly and quickly replaced by its standby machine under the condition of no influence on normal downstream process.

Owner:玉溪市新特科技有限公司

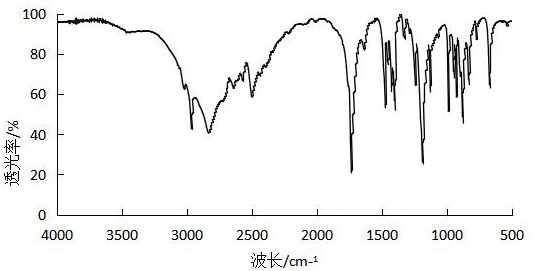

Scrub cream containing brown sugar and chamomile ultrafine powder and preparation method thereof

InactiveCN108210432APrevent drynessPromote absorptionCosmetic preparationsToilet preparationsSilicic acidAdditive ingredient

The invention provides scrub cream containing brown sugar and chamomile ultrafine powder. The scrub cream is prepared from the following raw materials in parts by weight: 24 to 30 parts of brown sugar, 5 to 10 parts of chamomile ultrafine powder, 3 to 8 parts of grape seed ultrafine powder, 3 to 5 parts of honeysuckle flower ultrafine powder, 5 to 8 parts of mung bean, 2 to 4 parts of black soya bean, 18 to 26 parts of green cucumber extracts, 10 to 15 parts of carrot extracts, 0.1 to 0.5 part of essential oil, 1 to 3 parts of silicic acid and 1 to 8 parts of honey. The brown sugar is used asscrub particles in the formula; the brown sugar has the effects of whitening, yellow removal and exfoliation, and is mild and inirritative. The silicic acid is also added in the ingredients, and can be dissolved into water. By using the preparation method provided by the invention, the materials are firstly prepared into concentrated cream; then, the silicic acid is added; therefore the water content of the concentrated paste is low; the dissolution quantity of the silicic acid in the exfoliation process is little; during the cleaning after the exfoliation is completed, the scrub cream meets water, a great amount of silicic acid is dissolved into water to form gel; cuticle removed by the scrub cream from the skin can be adsorbed; the skin injury is avoided; old cuticle can be brought away;the cleaning is convenient; the adsorption is clean.

Owner:河南健特生物科技集团有限公司

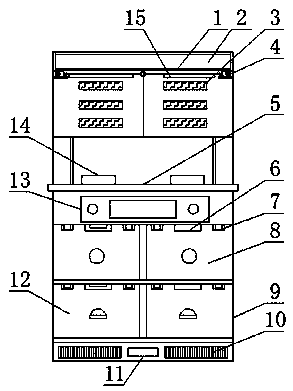

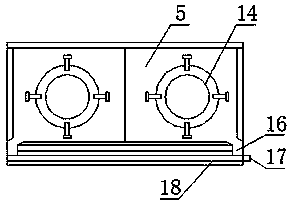

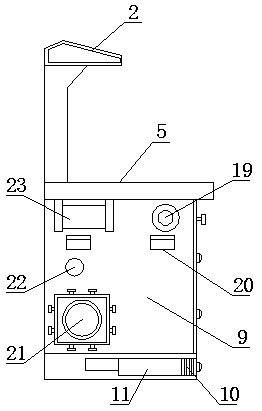

Adjustable integrated cooker capable of realizing convenient oil stain cleaning effect

PendingCN108061324AEasy to cleanAbsorb cleanDomestic stoves or rangesLighting and heating apparatusSuction forceCombustor

The invention discloses an adjustable integrated cooker capable of realizing a convenient oil stain cleaning effect. The integrated cooker comprises an integrated cooker body, a shelving bench is arranged above the integrated cooker body, oil fume suction openings are arranged at position, close to the bottom of the shelving bench, on the front surface of the shelving bench, the inner wall of theintegrated cooker body is fixedly provided with a driving motor, the left end of the driving motor is fixedly connected with a rotating shaft, baffle plates are arranged around the rotating shaft, a cooking bench is arranged below the oil fume suction openings, and combustors are arranged on the upper surface of the cooking bench. The integrated cooker has a scientific and reasonable structure, and is safe and convenient to use; the driving motor arranged in the invention drives the rotating shaft to rotate in order to control the movement of the baffle plates; when the combustor at one side is used, the oil fume openings at the one side are turned on to achieve the increase of the suction force through using the small oil fume suction openings, so oil fume can be completely sucked; and the cooking bench is provided with an oil stain discharging channel, and the oil stain discharging channel is connected with a connecting tube to directly discharge oil stains, so the oil stains generated in cooking can be conveniently cleaned, and the integrated cooker can be used in a humanized manner.

Owner:嵊州市惠宁达厨房电器有限公司

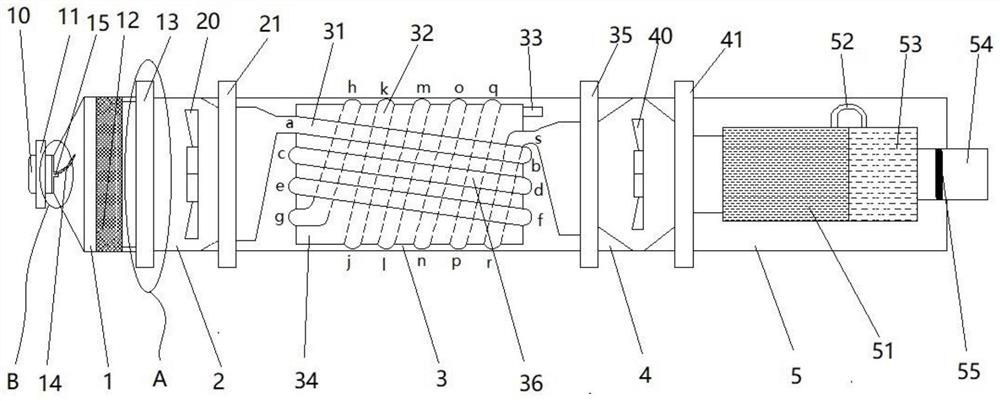

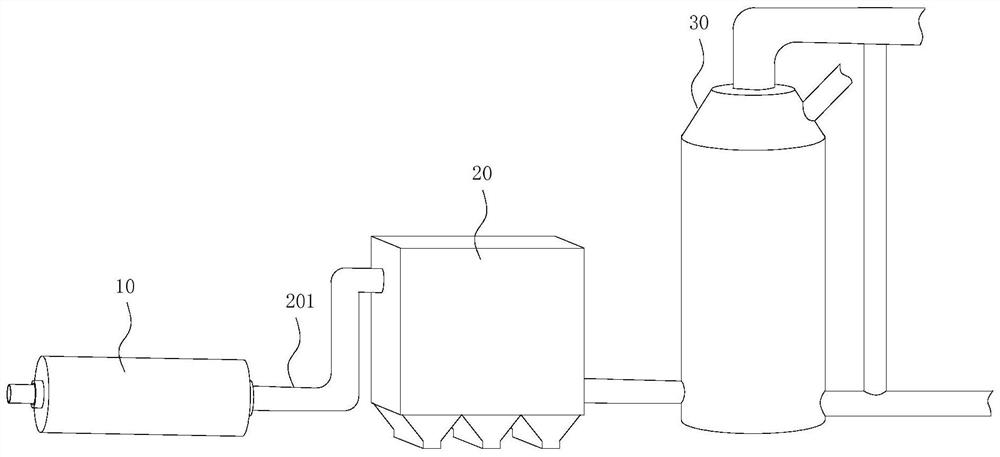

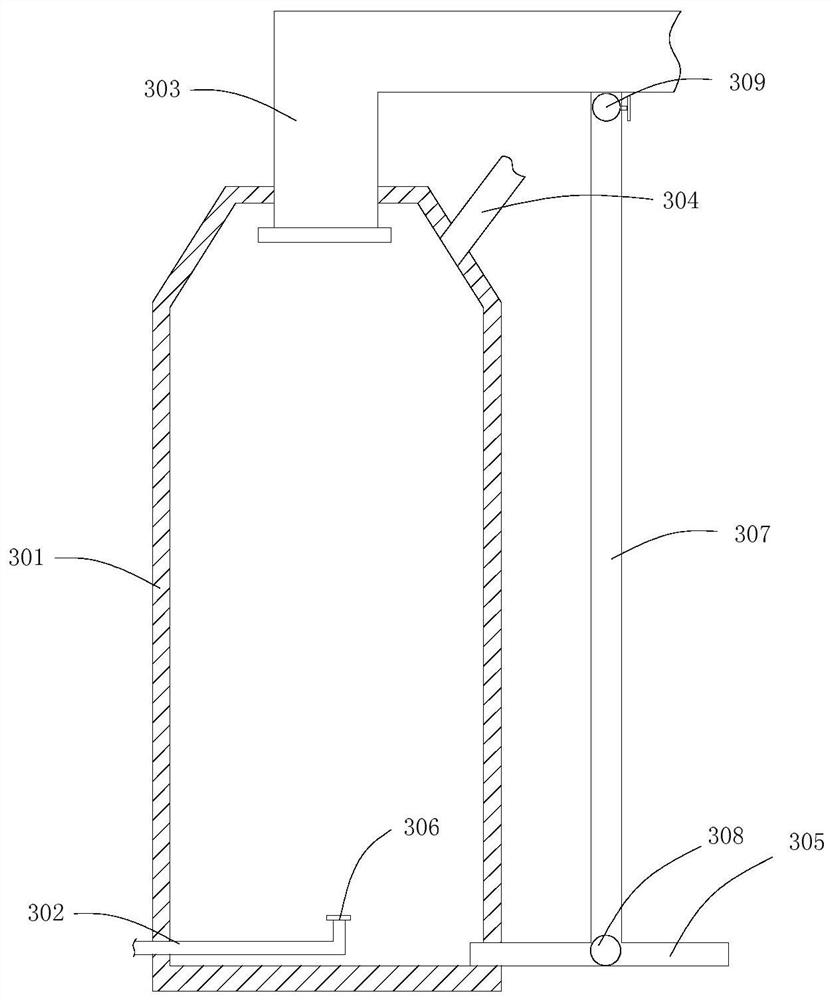

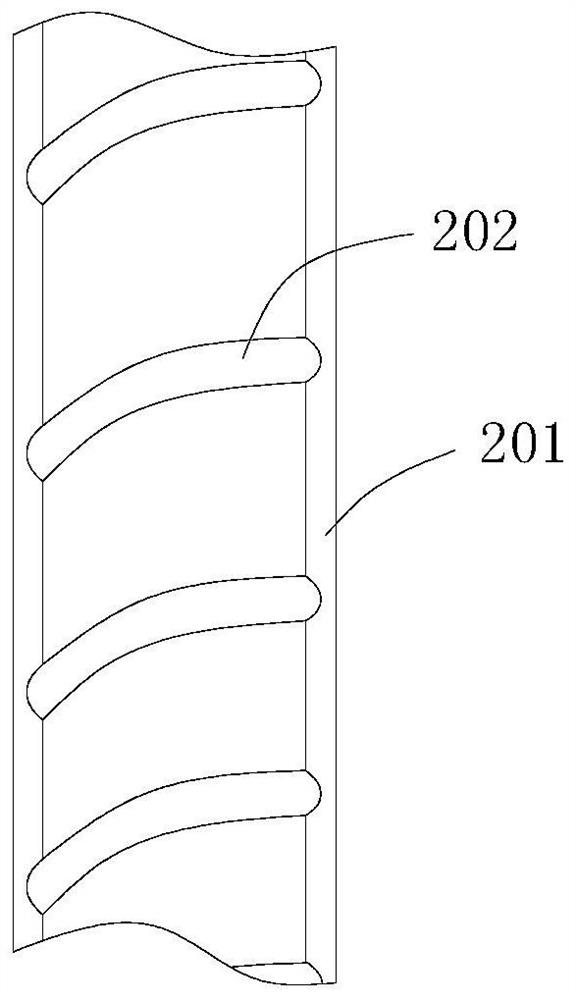

Automobile exhaust absorption and purification device and using method thereof

ActiveCN113123851AIncrease contact timeStrengthen full physical absorptionExhaust apparatusSilencing apparatusParticulatesDesiccant

The invention belongs to the field of air pollution prevention and control, and particularly relates to an automobile exhaust absorption and purification device and a using method thereof. The automobile exhaust absorption and purification device comprises an isolation section, a first-stage wind power section, an exhaust absorption section, a second-stage wind power section and a purification section. The isolation section comprises an exhaust port, a fixing ring, a filter screen, a first connecting position and a wind guide device, and the first-stage wind power section comprises a first-stage fan and a second connecting position. The exhaust absorption section comprises spiral pipes, a water tank, a third connecting position and particles, the second-stage wind power section comprises a second-stage fan and a fourth connecting position, and the purification section comprises a purification agent and a drying agent. Harmful gas in exhaust is fully physically absorbed in a transverse and longitudinal double-spiral-pipe mode, and absorption is achieved in combination with a chemical agent, so that it is ensured that harmful gas in exhaust can be completely absorbed, and the maintenance cost can be reduced by adopting a multi-stage assembly mode.

Owner:珠海六和节能投资有限公司

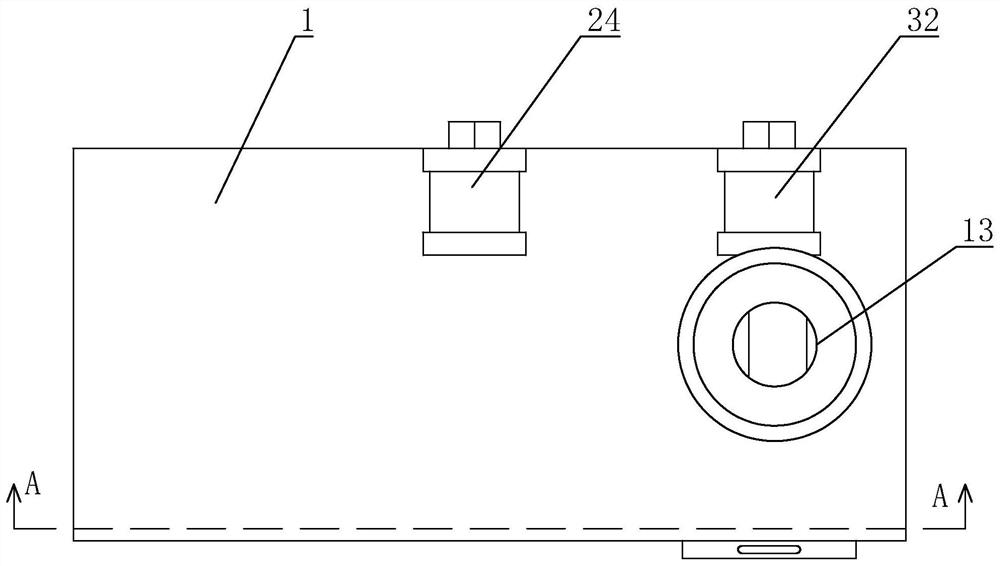

Carriage excess material sweeping and collecting device

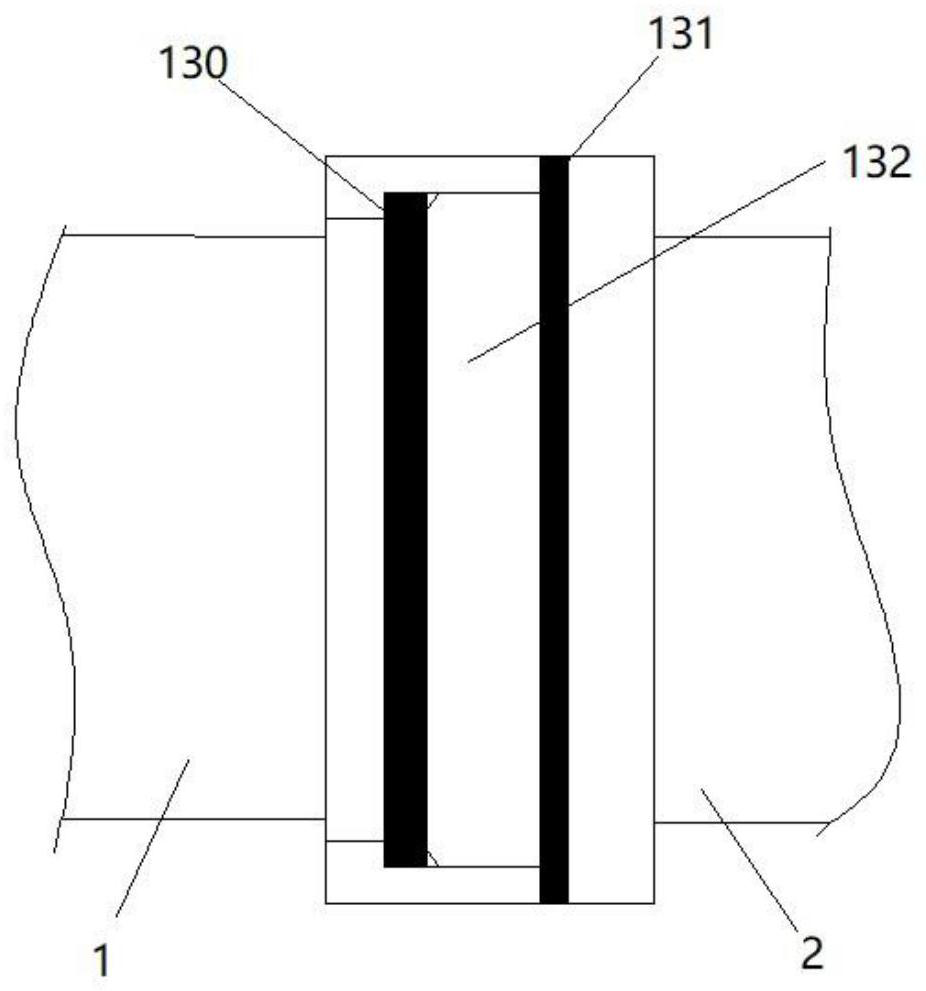

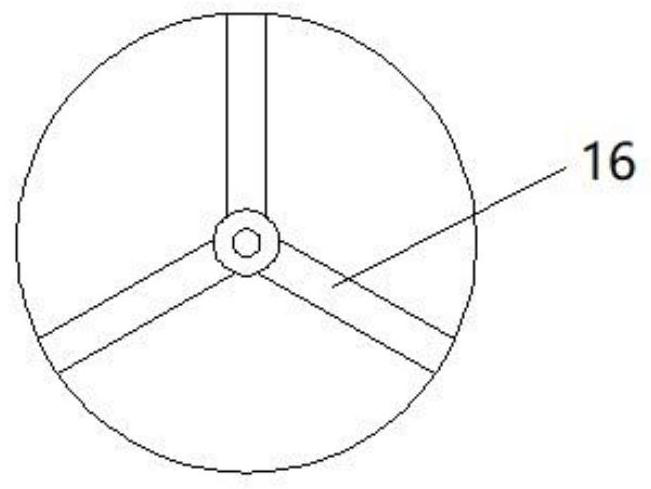

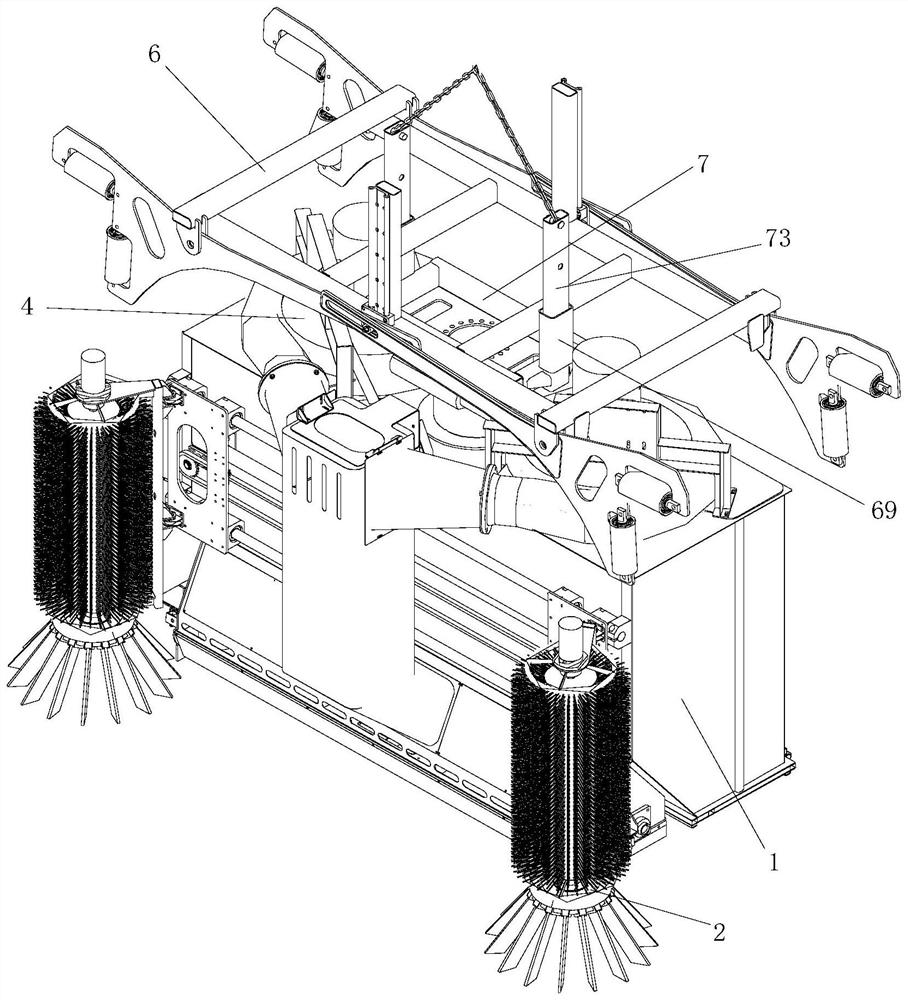

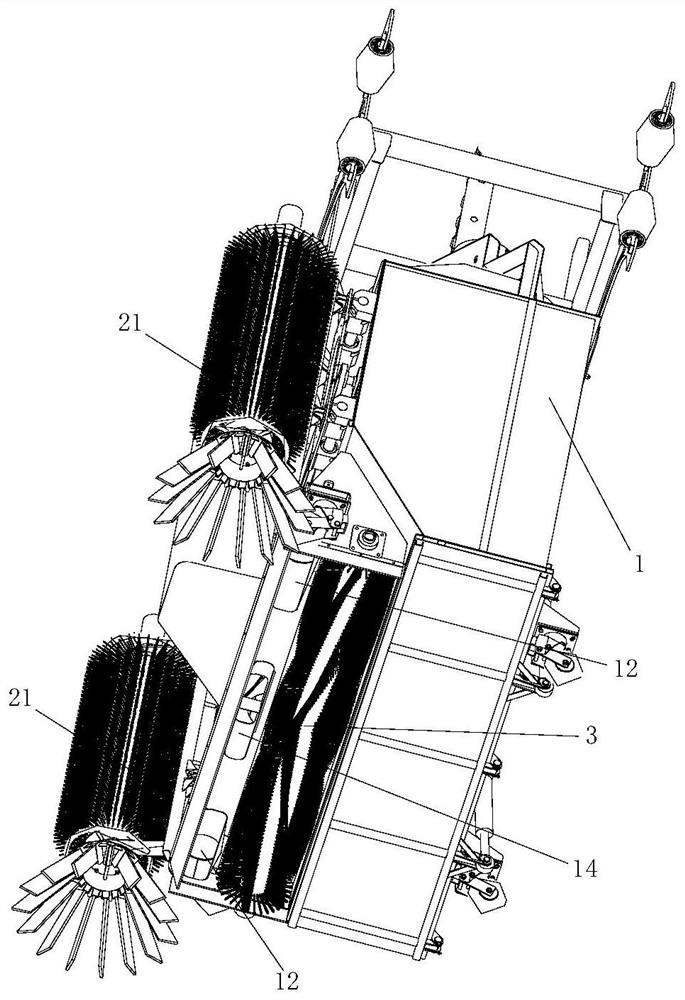

PendingCN112277890AHighly integratedImprove adsorption capacityVehicle cleaningEngineeringMechanical engineering

The invention discloses a carriage excess material sweeping and collecting device. The device comprises a box body, wherein one or more vertical brush mechanisms and one or more transverse brush mechanisms used for sweeping residues are arranged on the box body, a suction nozzle is arranged at the bottom of the box body, an adsorption mechanism is further arranged on the box body, a collecting binis arranged in the box body, and a filtering mechanism is arranged in the collecting bin; the absorption mechanism is communicated with the suction nozzle through the collection bin and used for enabling residues sucked from the suction nozzle to be filtered by the filtering mechanism in the filtering collection bin and to be collected in the collection bin during negative pressure absorption. The device has advantages of being high in integration level, excellent in adsorption cleaning effect, energy-saving and environment-friendly.

Owner:湖南一程智能科技有限公司

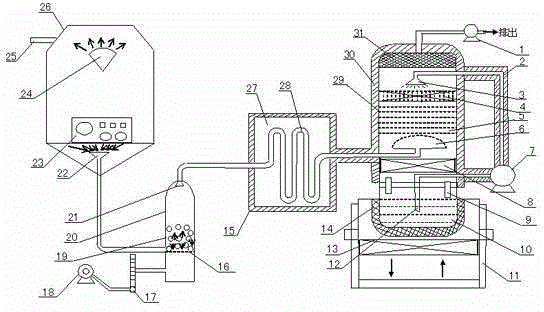

Laboratory nano material gas incineration absorbing apparatus

InactiveCN102824811AUrgent need to meet safe emissions requirementsSolve a major technical problem in adsorption treatmentDispersed particle separationIncinerator apparatusHazardous substanceAir pump

The invention provides a laboratory nano material gas incineration absorbing apparatus which is characterized in that gas containing a nano material, which is collected from a nano laboratory, is conveyed to a liquating cabin through a collected gas input port so as to be mixed with compressed air input by another path under the stirring of a floating ball, and the mixture is diluted and then conveyed into an incineration bent pipe passage in an ultra-temperature furnace chamber; and the nano material gas subjected to high-temperature burning and incineration can be used for incinerating and digesting the whole or major nano material; after incineration, even if residual gas containing harmful substances enters into an absorbing rubber cabin and performs liquid-gas reverse exchange with preheated gel liquid under the driving of a colloid pump, an air pump drives clean gas to be exhausted through a dry grid, and the harmful substances left through exchange are adsorbed to a gel pool by gel so as to be accumulated, stored and recondensed for recovery processing. The laboratory nano material gas incineration absorbing apparatus provided by the invention has the beneficial effects that the technical problem of adsorption processing of laboratory nano material exhaust gas is solved; and special equipment which is safe, convenient, rapid and effective and can be used for thoroughly and cleanly adsorbing and processing laboratory nano material gas is provided.

Owner:TIANJIN HOPE IND & TRADE

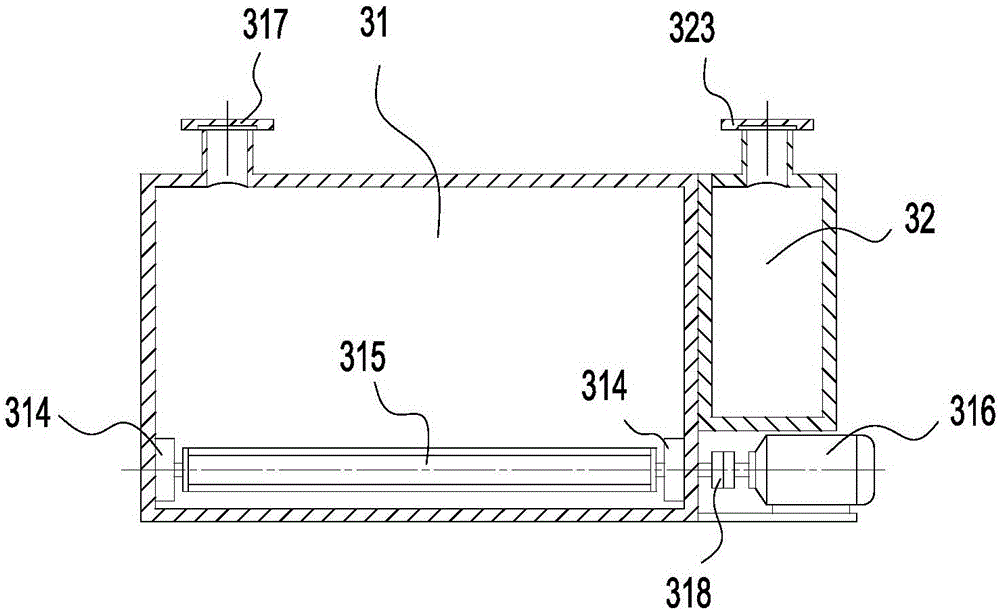

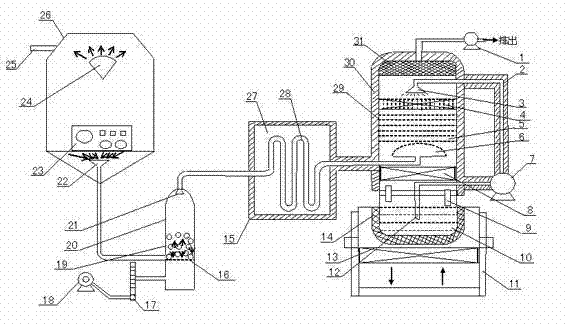

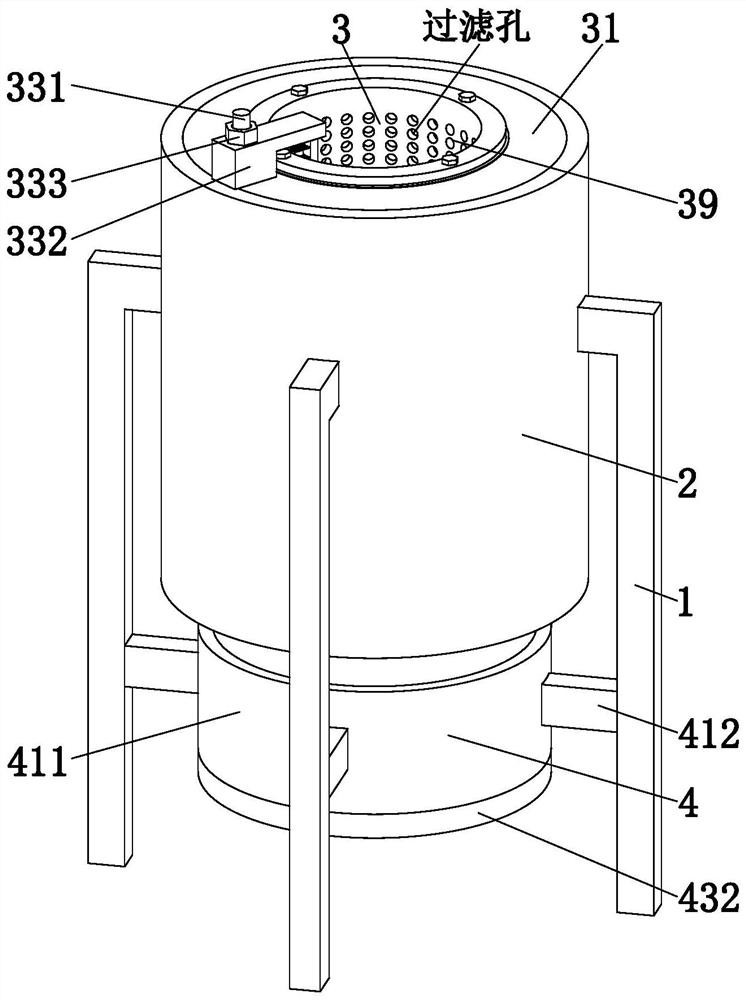

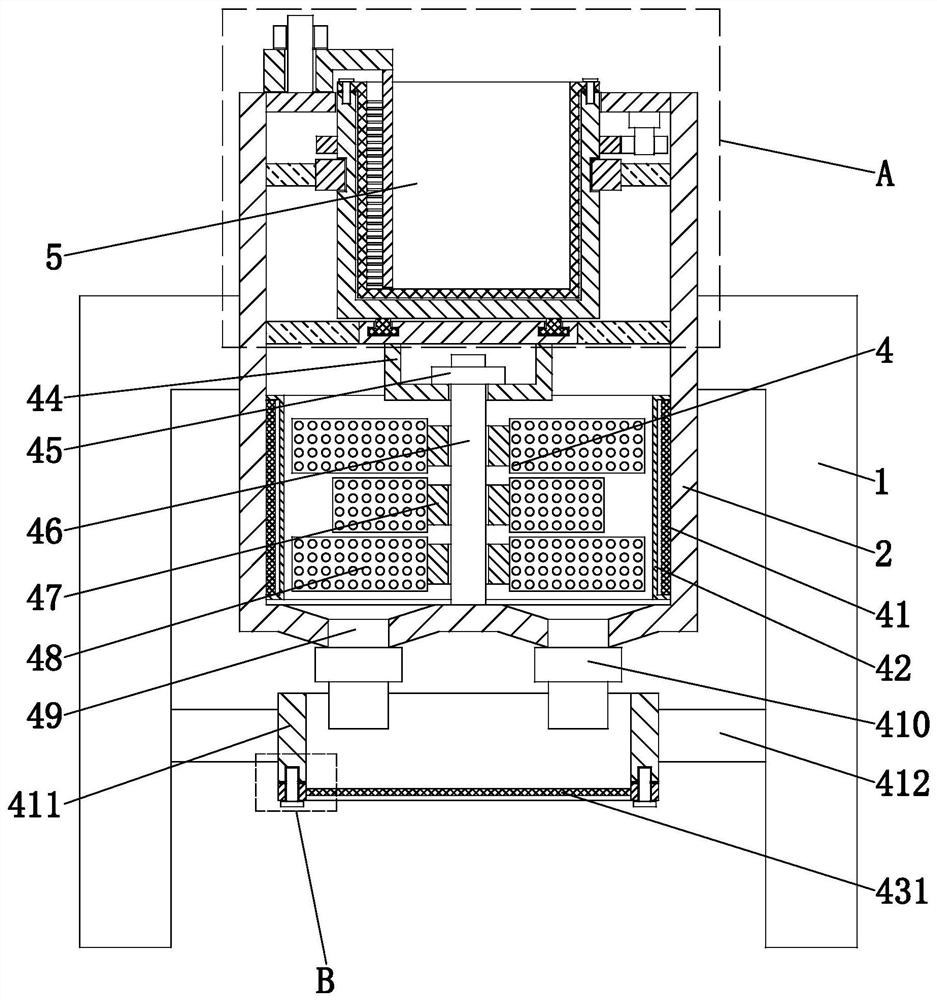

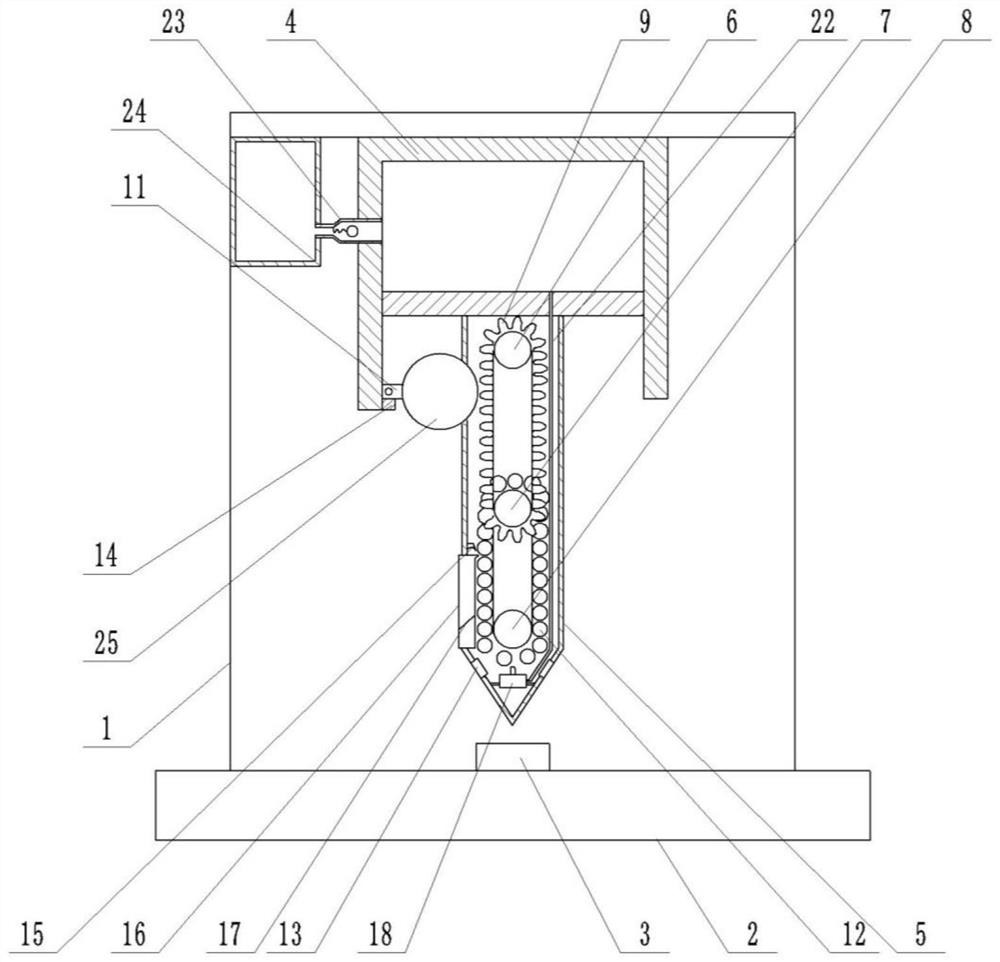

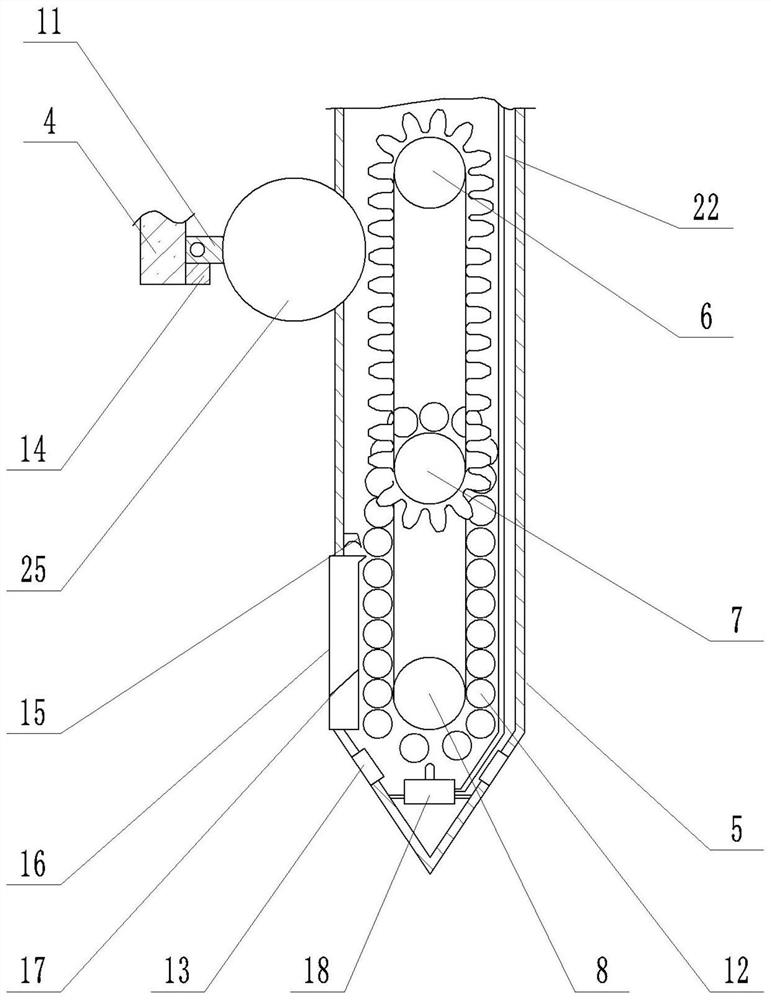

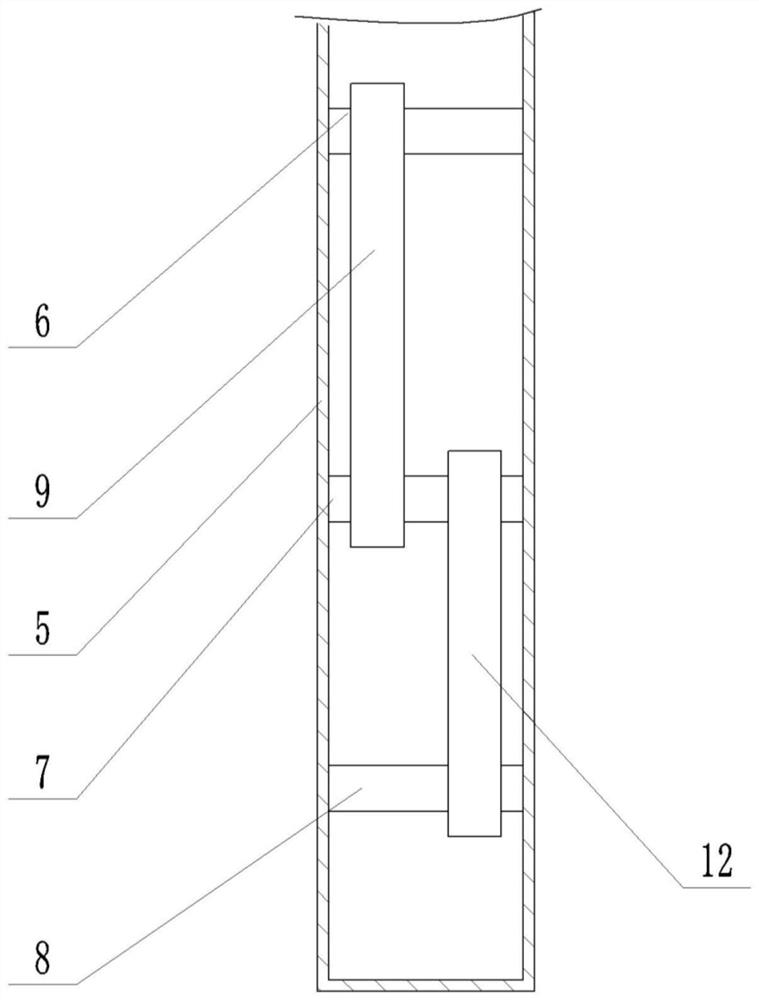

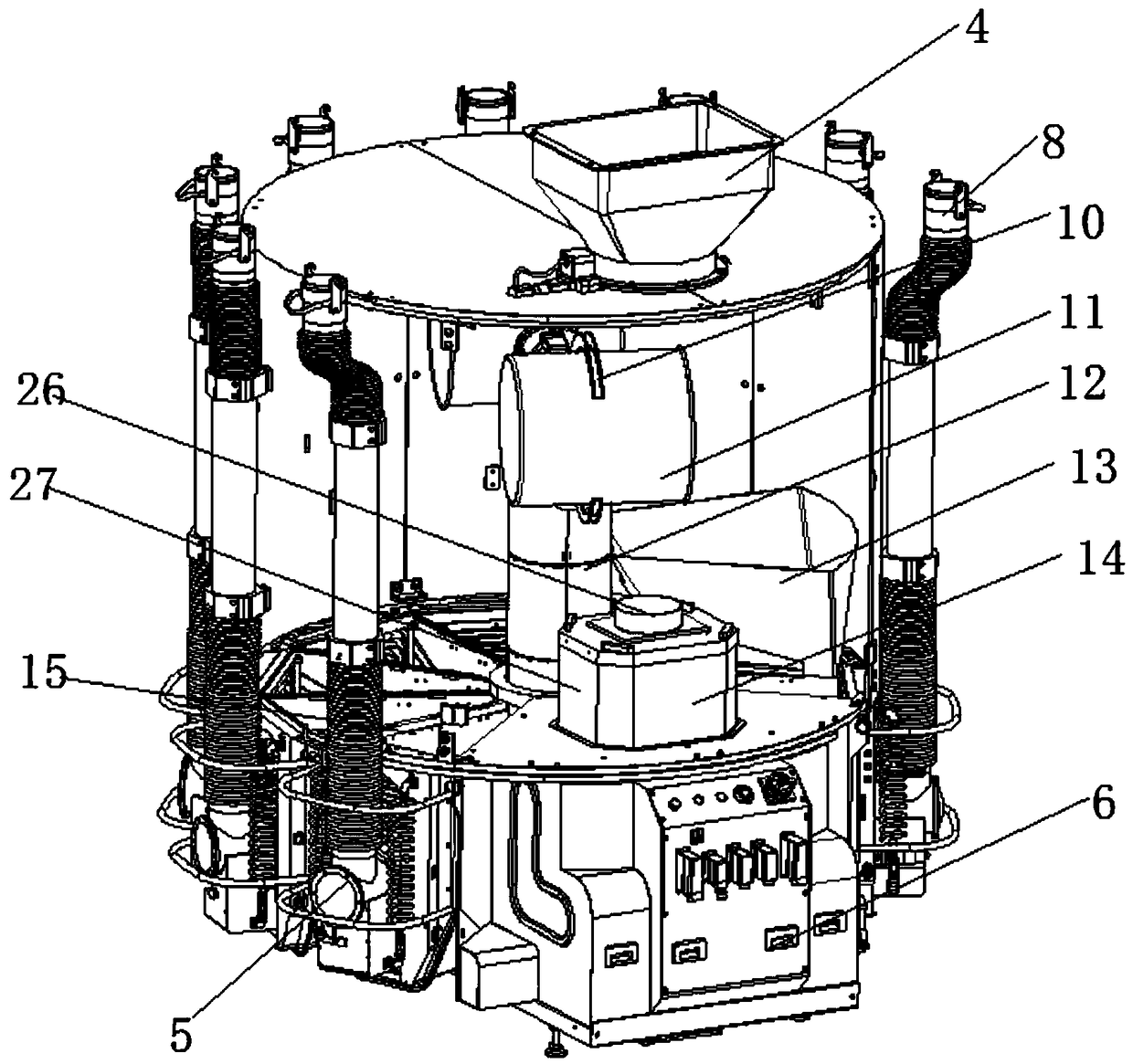

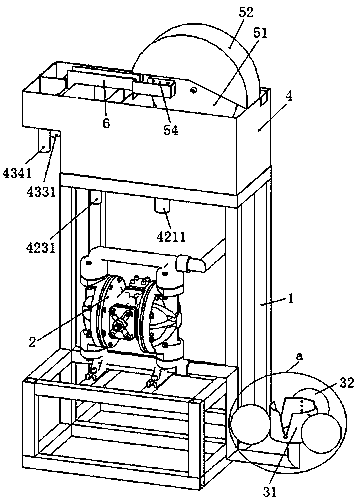

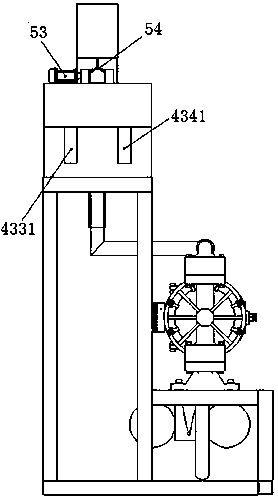

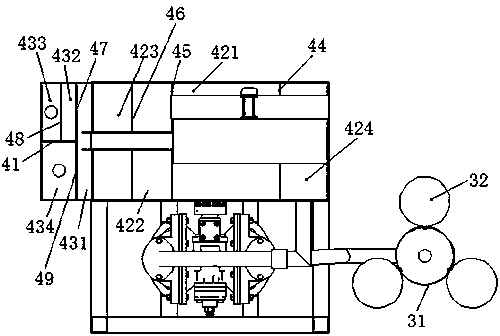

Water-based cutting fluid filtering, purifying and regenerating treatment system and treatment method

PendingCN112811707AIncrease production costEffective filteringWater/sewage treatment by centrifugal separationTreatment involving filtrationProcess engineeringEnvironmental engineering

The invention provides a water-based cutting fluid filtering, purifying and regenerating treatment system and method. The water-based cutting fluid filtering, purifying and regenerating treatment system comprises a supporting frame, a filtering tank, a centrifugal filtering mechanism and a magnetic separation screening mechanism. The invention provides a water-based cutting fluid filtering, purifying and regenerating treatment system and a treatment method, which can solve the following problems in the water-based cutting fluid filtering, purifying and regenerating treatment process: a, when the water-based cutting fluid cools and lubricates a cutter, iron chips and other metal particles with different sizes are generated during metal cutting and grinding, and then various dirt adhered to the surface of metal is gathered in the water-based cutting fluid, if the water-based cutting fluid is directly abandoned differently, resource waste is caused, and the production cost is greatly increased; and b, in a conventional recovery process of the water-based cutting fluid, only scrap iron in the water-based cutting fluid is simply filtered, but the fine particle scrap iron contained in the water-based cutting fluid is not completely filtered, and various non-metal dirt contained in the water-based cutting fluid is not completely and effectively filtered.

Owner:周良茂

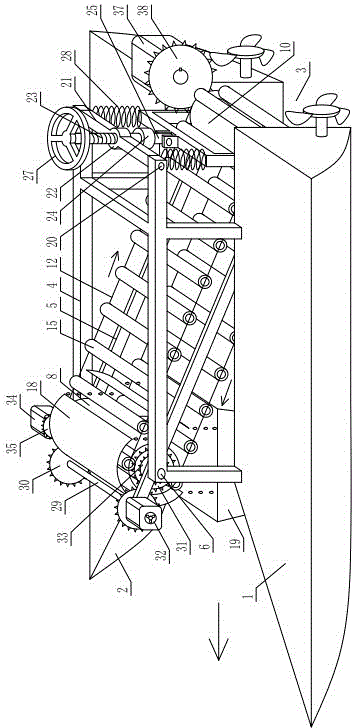

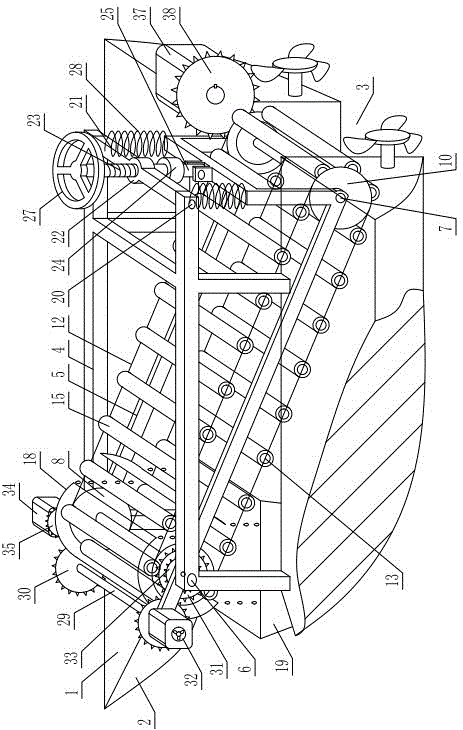

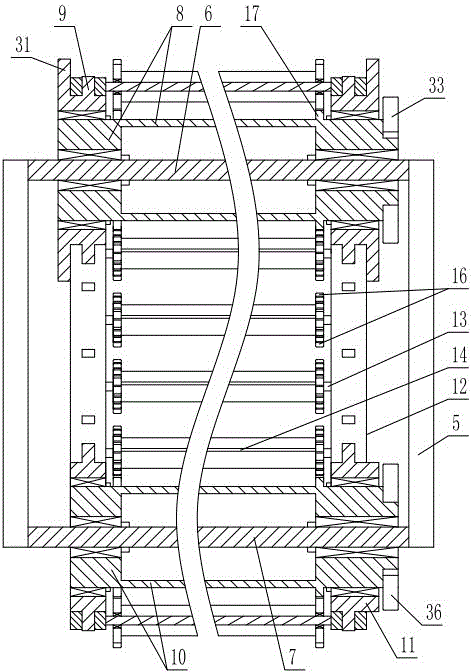

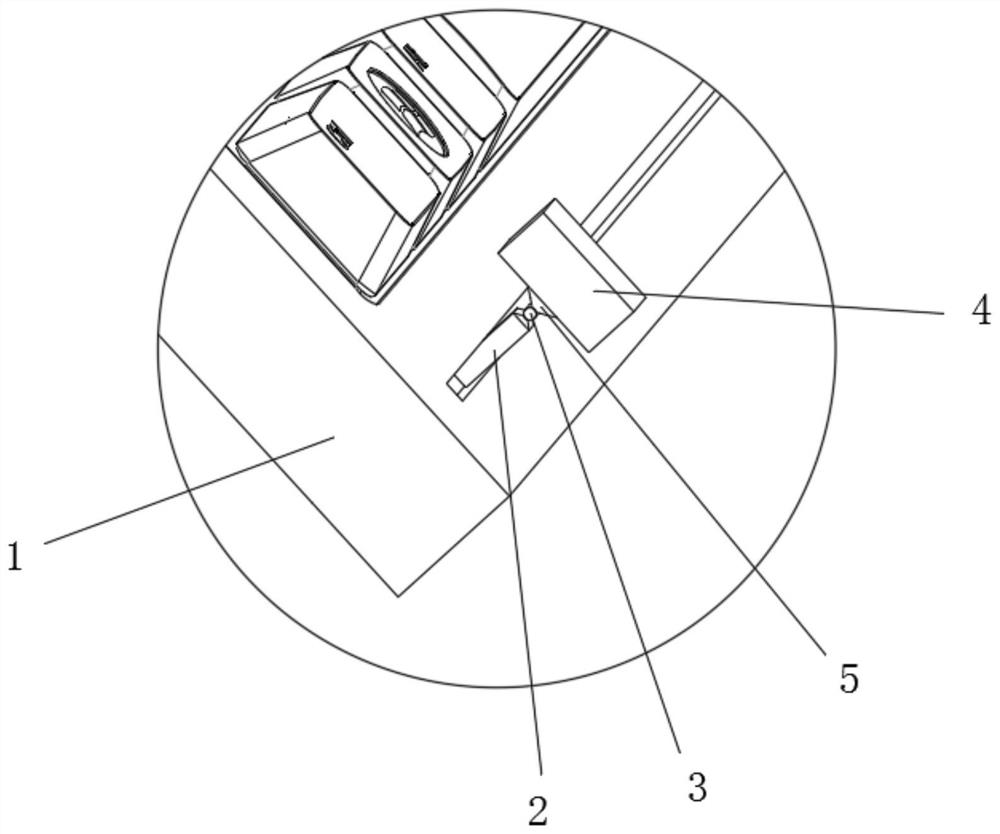

Power-line repairing device

InactiveCN105314072AReasonable structureHigh oil absorptionWater cleaningWaterborne vesselsEngineeringMechanical engineering

The invention discloses a power-line repairing device. The power-line repairing device comprises a ship and is structurally characterized in that a gap is formed below the ship, an inclined frame which corresponds to the gap and is provided with the high front portion and the low back portion is hinged to the front portion of a loading frame of the ship, an inclination adjusting device for adjusting the inclination degree of the inclined frame is installed between the back portion of the loading frame and the back end of the inclined frame, the front end and the back end of the inclined frame are each provided with an upper roller and a lower roller, each upper roller and the corresponding lower roller which are arranged on one side are sleeved with an annular conveying belt in a transmitting mode, and transversely-arranged inter-belt shafts are correspondingly connected between the two conveying belts and rotationally sleeved with a felt frame. By means of the power-line repairing device, power-line repairing can be assisted, oil can be thoroughly, completely and stably absorbed, the amount of missed oil is small, deoiling is thorough and complete, recycling efficiency is high, the oil absorption effect is good, operation and maintenance are easy, and cost is low.

Owner:钮振伟

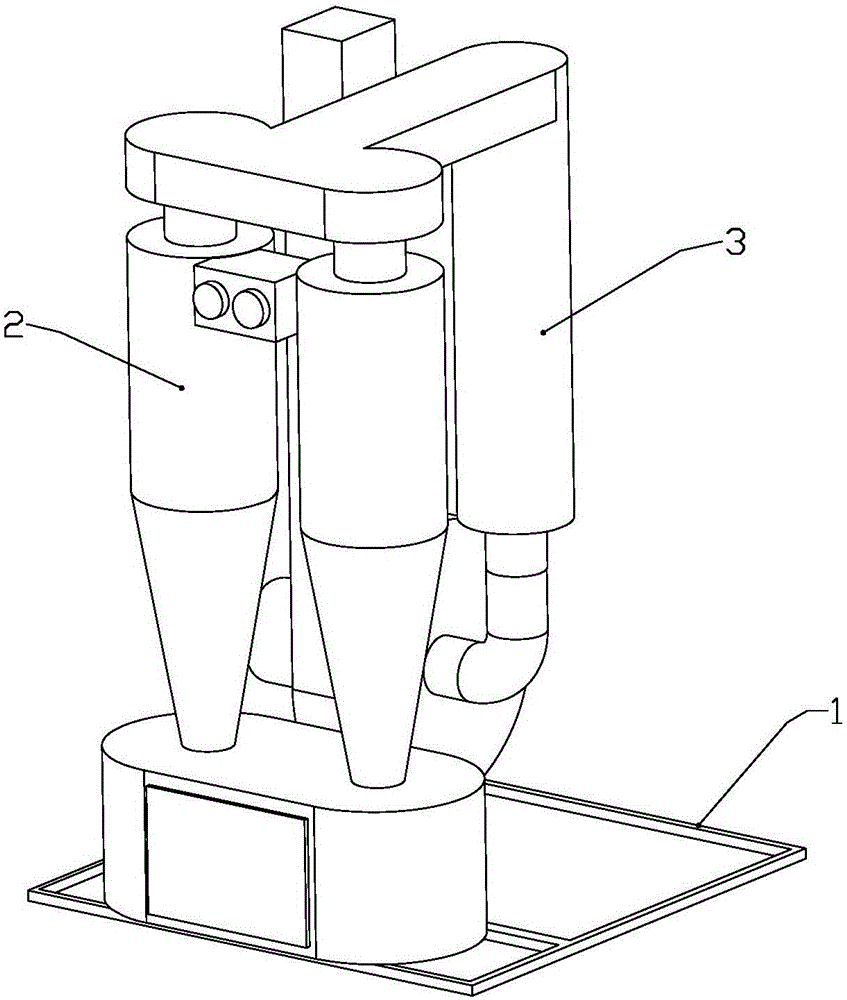

Road repair sundry and dust removal device and cleaning trolley

InactiveCN105839574AAddress shockImprove work efficiencyCombination devicesRoad cleaningBaghouseEngineering

The invention discloses a road repair sundry and dust removal device and a cleaning trolley. The road repair sundry and dust removal device comprises a base, two cyclone dust removers, a bag-type dust remover, hoses, a dust removal plain trolley, a fan and power generation equipment. The cyclone dust removers, the bag-type dust remover and the fan are fixed to the base. The two cyclone dust removers are arranged in parallel. Air inlets of the two cyclone dust removers are connected with the two hoses. The other ends of the hoses are fixed to the dust removal plain trolley through a steel hopper. Dust outlets in the tops of the cyclone dust removers are connected to the bag-type dust remover. The fan is connected to the back face of the bag-type dust remover through a pipeline. The fan supplies electricity to the power generation equipment. The road repair sundry and dust removal device is used for working on milled and planed concave-convex road surfaces and particularly used for thoroughly sucking sundries in dead corners and grooves.

Owner:JINAN KINGYUE HIGHWAY ENG

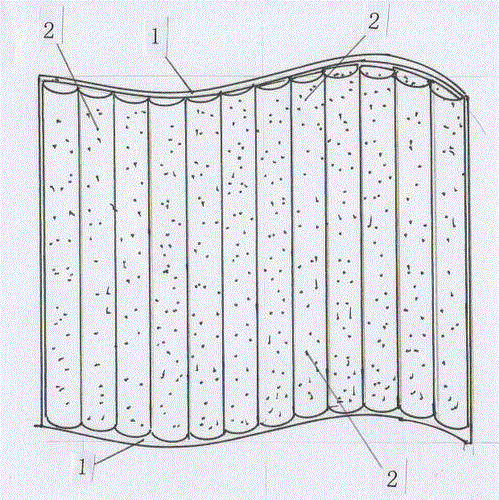

Device for removing rainwater on umbrella

The invention provides a device for removing rainwater on an umbrella. Multiple densely-arranged sponge strips are distributed on a windable plate. When the device is used, the side, where the sponge strips are distributed, of the windable plate can be wound around the umbrella with rainwater, and therefore the rainwater on the umbrella can be adsorbed thoroughly.

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

Gear scrap cleaning device

PendingCN113857589AAvoid situations that require downtime for cleaningEasy to cleanGear-cutting machinesMaintainance and safety accessoriesHydraulic cylinderGear wheel

The invention belongs to the technical field of gear machining, and particularly relates to a gear scrap cleaning device. The gear scrap cleaning device comprises a machine frame, a workbench is arranged on the machine frame, a hydraulic cylinder is arranged on the machine frame, a cutter is installed on a piston of the hydraulic cylinder, and a scrap cleaning device is arranged on the cutter; the scrap cleaning device comprises a first rotating shaft, a second rotating shaft, a third rotating shaft and a gear, the first rotating shaft, the second rotating shaft and the third rotating shaft are rotationally arranged on the side walls of the two ends of the cutter, the first rotating shaft and the second rotating shaft are connected with a chain, a first opening is formed in the cutter, the chain is meshed with the gear through the first opening, a connecting rod is arranged on the side wall of the hydraulic cylinder, the gear is fixed on the connecting rod. According to the scheme, the cutter is provided with a magnet and a second opening, so that scrap iron is sucked away when the scrap iron is just generated, the scrap iron cannot adhere to the gear, the gear is kept clean and dry, and the situation that the sight of an operator is affected by splashed scrap iron is avoided.

Owner:CHONGQING RUNYUE MACHINERY CO LTD

Tubular pump-free suction mechanism

The invention discloses a tubular pump-free suction mechanism. The mechanism consists of a pickling tank, a square cone cover, drooping soft plates, a mist suction pipe, an anti-corrosion induced draft fan and a treatment tower, wherein the pickling tank is installed on the ground, the square cone cover is arranged right above the pickling tank and communicates with the pickling tank, the mist suction pipe is arranged above the square cone cover, one end of the anti-corrosion induced draft fan is connected with an outlet of the mist suction pipe, and the other end of the anti-corrosion induceddraft fan is connected with the treatment tower. The mechanism is characterized in that drooping soft plates are arranged around the outer side of a mist storage plate. According to the invention, acid-base mist is sucked through series connection and parallel connection, and the mechanism has the advantages of low power, thorough suction, energy consumption cost reduction and energy conservation.

Owner:丹阳市延陵镇弘理木材厂

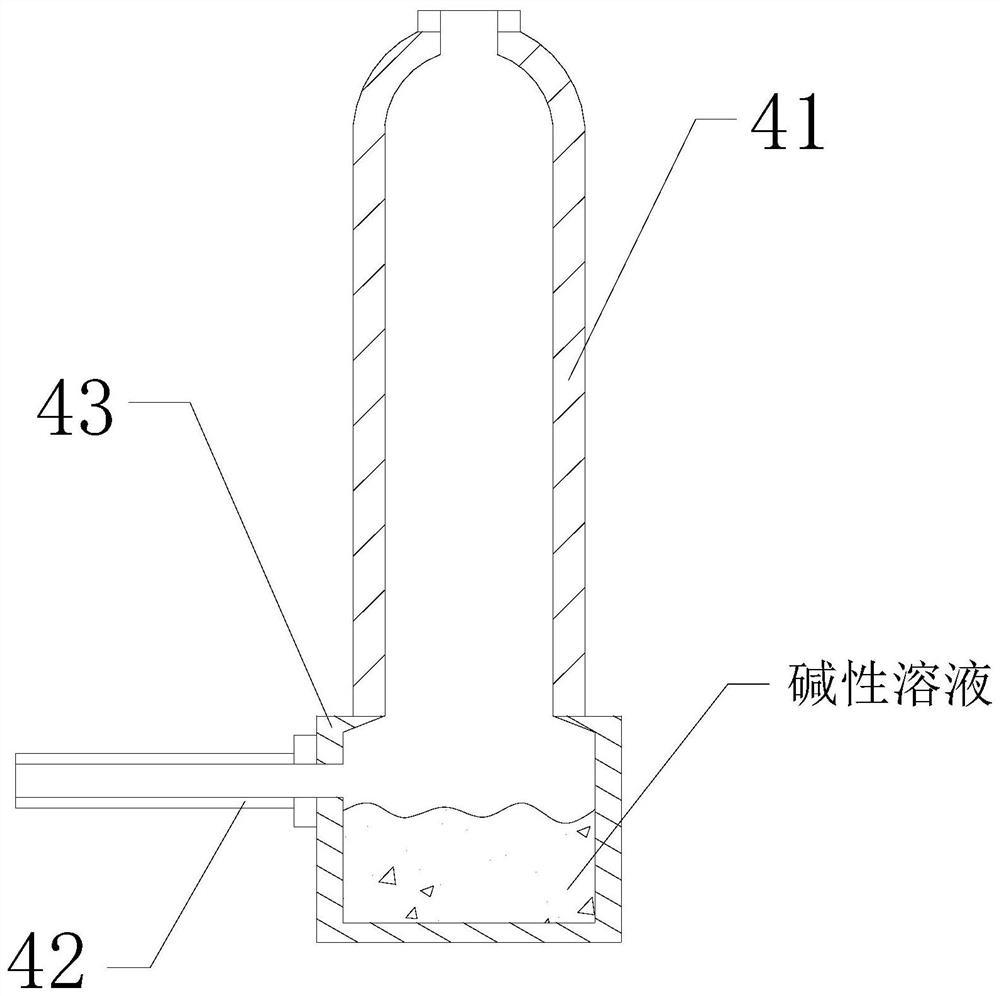

Low-temperature industrial toxic waste gas denitration equipment

PendingCN113663498AAbsorb cleanAvoid discharge togetherDispersed particle separationToxic gasExhaust fumes

The invention discloses low-temperature industrial toxic waste gas denitration equipment which structurally comprises a gas guide pipe, an oxidation bin, a gas inlet pipe and a denitration cylinder; the oxidation bin is fixed to the rear end of the gas guide pipe, the gas inlet pipe is connected with a flange at the rear end of the oxidation bin, the top of the denitration cylinder is connected with the gas guide pipe, gas without nitrate substances extrudes a sliding block, and the sliding block can slide leftwards along a middle fixing rod, so that gas can be exhausted outwards through the space between the sliding block and the inner wall of an outer pipe; and through the process, when the sliding block is extruded to slide leftwards, time can be won for an alkaline solution to absorb nitrate substances; and through thrust generated by poisonous gas entering the denitration cylinder from top to bottom on the upper surfaces of blades, the blades can drive a rotating shaft to rotate along a bottom block, so that an outer swing plate can stir an alkaline solution along with rotation of a rod body under the cooperation of an outer convex block.

Owner:赖汉龙

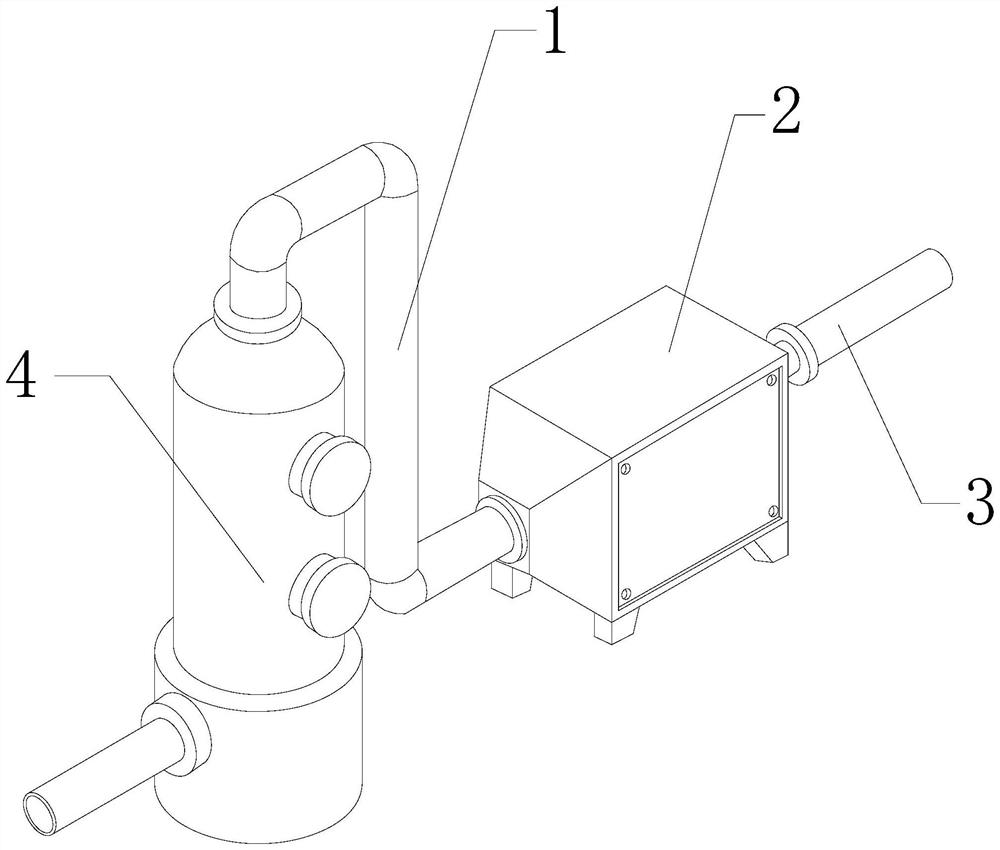

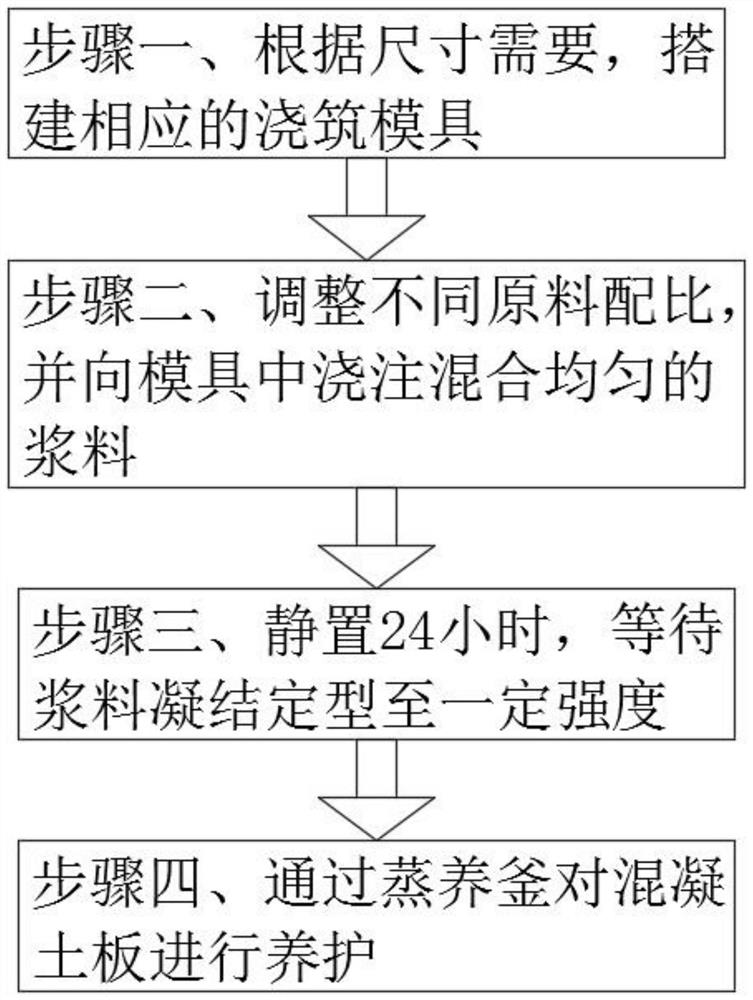

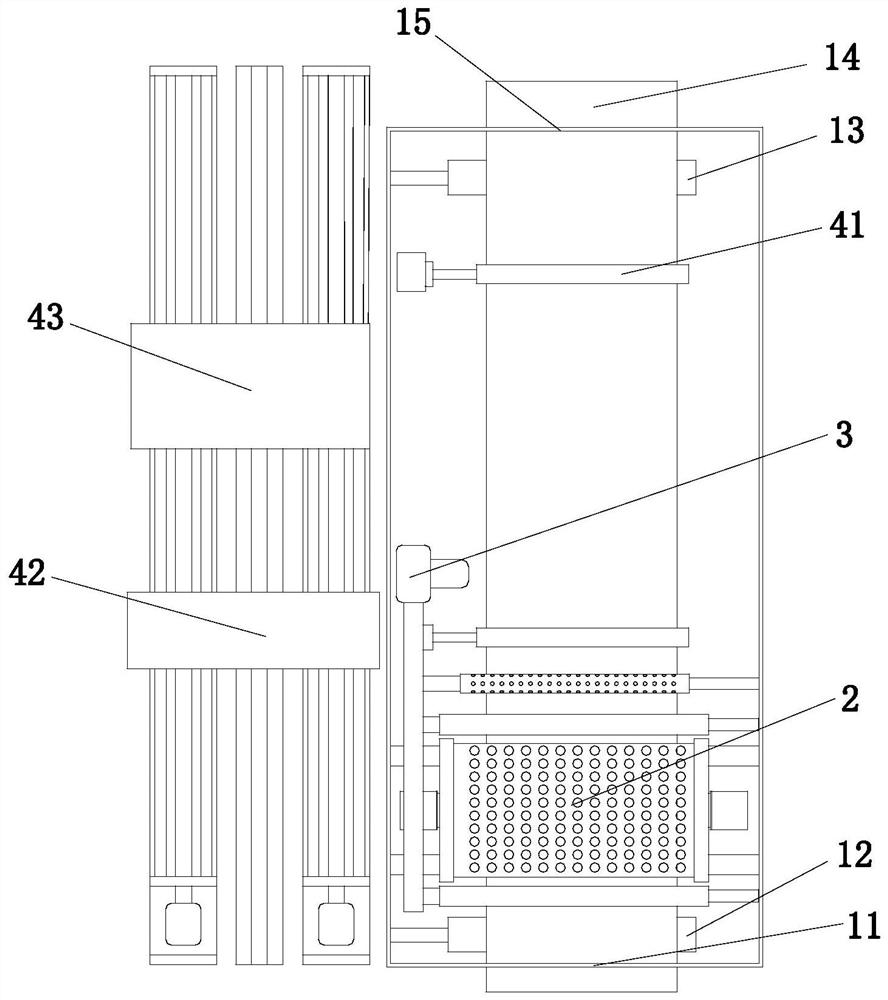

Autoclaved aerated concrete slab and preparation method thereof

PendingCN114770736AAvoid problems with poor environmental qualityIncrease contact areaCombination devicesConstruction materialAir pumpSlurry

The invention discloses an autoclaved aerated concrete slab and a preparation method thereof, and relates to the technical field of aerated concrete structures, the autoclaved aerated concrete slab comprises a steam pressurized concrete slab, and the inner wall of the steam pressurized concrete slab is fixedly connected with a steel reinforcement framework. According to the concrete slurry mixing device disclosed by the invention, by adopting the cooperation of the dust suction cover, the dust guide pipe, the ingress pipe, the adsorption treatment box, the water inlet pipe, the air outlet pipe and the blow-off pipe, when the concrete slurry mixing device starts to work and a large amount of dust is generated at the feed hopper, firstly, air carrying the dust is sucked through the dust suction cover and the dust guide pipe by an air suction pump; gas is introduced into the adsorption treatment box through the introduction pipe for adsorption treatment, adsorption liquid is sprayed out through the water inlet pipe, dust carried in the gas is completely adsorbed, the gas subjected to adsorption treatment is discharged through the gas outlet pipe, sewage adsorbing the dust is discharged through the blow-off pipe, and the dust is prevented from drifting in the air; and the environment quality of a production field is poor.

Owner:杨牧夫

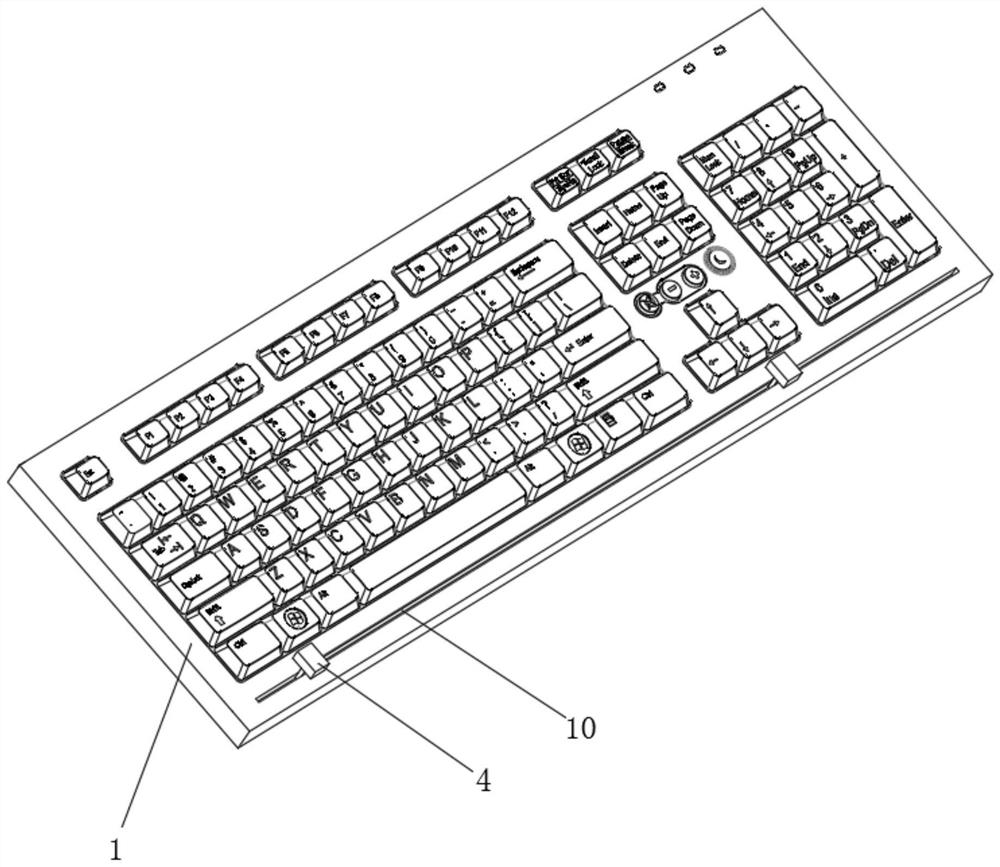

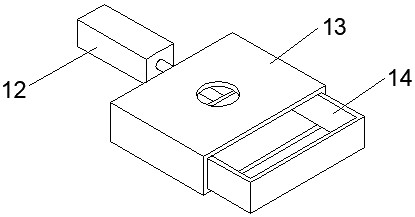

Movable type cleaning mechanism for keyboard

The invention discloses a movable type cleaning mechanism for a keyboard. The movable type cleaning mechanism for the keyboard comprises a keyboard body, wherein a sliding chute is formed in the bottom part of the keyboard body; moving rods are arranged in the sliding chute; one ends of the moving rods are located in the sliding chute; the other ends of the moving rods stretch out of the sliding chute; rotating rods are arranged above the moving rods; box blocks are arranged above the rotating rods; connecting pieces are arranged between the box blocks and the rotating rods; telescopic rods and sucking pumps are arranged in the box blocks; the telescopic rods penetrate through one side walls of the box blocks and are parallel to the keyboard body; the telescopic rods comprise outer rods and inner rods; the large outer rods and the small inner rods are connected in a sleeving way; pinch handles are arranged on the inner rods; openings in one ends, far away from the box blocks, of the inner rods face the keyboard body; the sliding chute is of a convex-shaped structure; the moving rods are matched with the sliding chute and are of convex-shaped structures; and the box blocks and the top ends of the moving rods form rotating structures through the rotating rods. According to the movable type cleaning mechanism for the keyboard provided by the invention, the openings of the inner rods can stretch into the key groove so as to cleanly adsorb impurities in the key groove, so that different areas on the keyboard can be cleaned.

Owner:刘勇林

Electrolytic aluminum waste magnetic separation equipment

The invention relates to electrolytic aluminum waste magnetic separation equipment, and belongs to the technical field of electrolytic aluminum waste recovery. The equipment comprises a magnetic separation cylinder, wherein a magnetic separation roller and an overturning roller are rotatably connected between two vertical side walls of the magnetic separation cylinder, an arc-shaped first supportplate is fixedly connected to the inner wall of the magnetic separation cylinder, an arc-shaped second support plate is slidably connected to the magnetic separation cylinder, a material clearing knife is fixedly connected to the end, away from the overturning roller, of the first supporting plate, one end of the material clearing knife makes contact with the side wall of the magnetic separation roller, a first material box used for containing iron impurities is arranged under the material clearing knife, a second material box used for containing carbon particles is arranged under the overturning roller, a feeding port is formed in the upper end face of the magnetic separation cylinder, waste enters the magnetic separation cylinder through the feeding port, the overturning roller turns over the waste to guarantee that the waste makes full contact with the magnetic separation roller, the iron impurities on the magnetic separation roller are removed through the material clearing knife, the removed iron impurities fall into the first material box along the material clearing knife, and the second supporting plate is pulled, so that carbon particles with the iron impurities removed arepushed into the second material box.

Owner:SHANDONG NANSHAN ALUMINUM

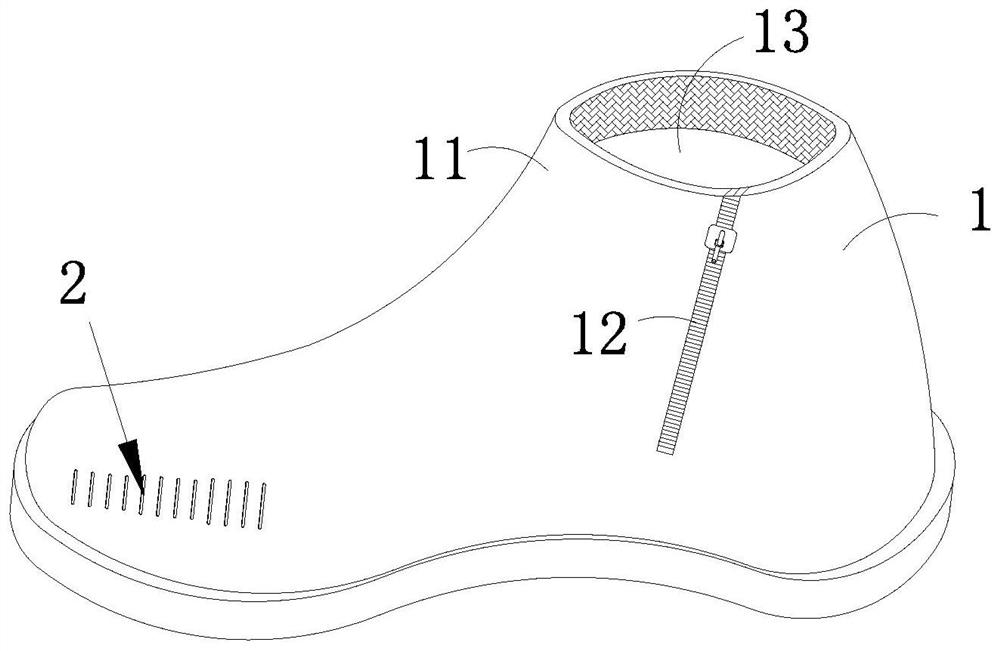

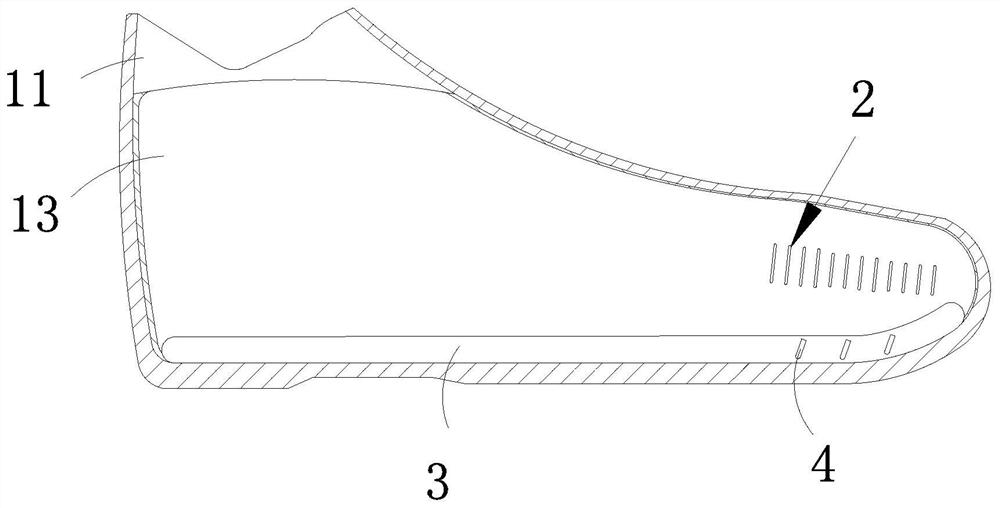

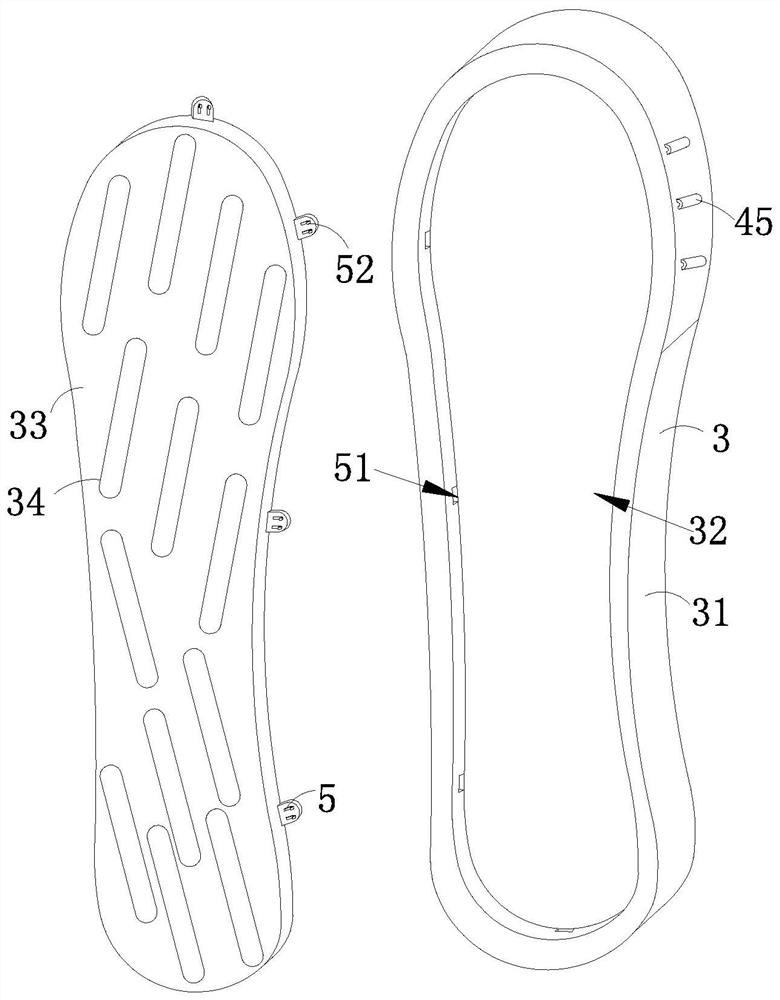

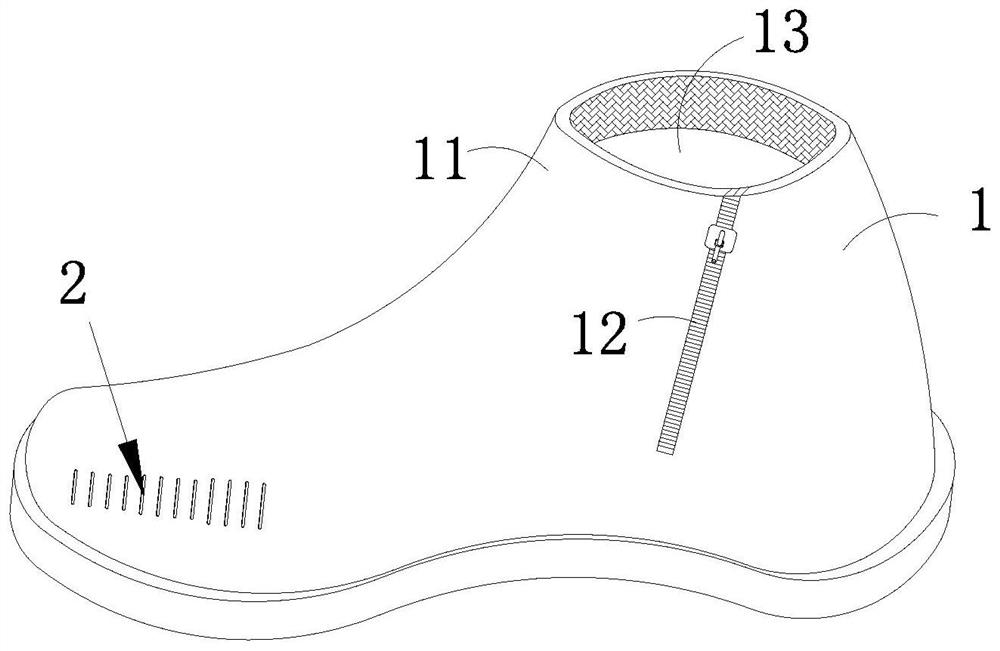

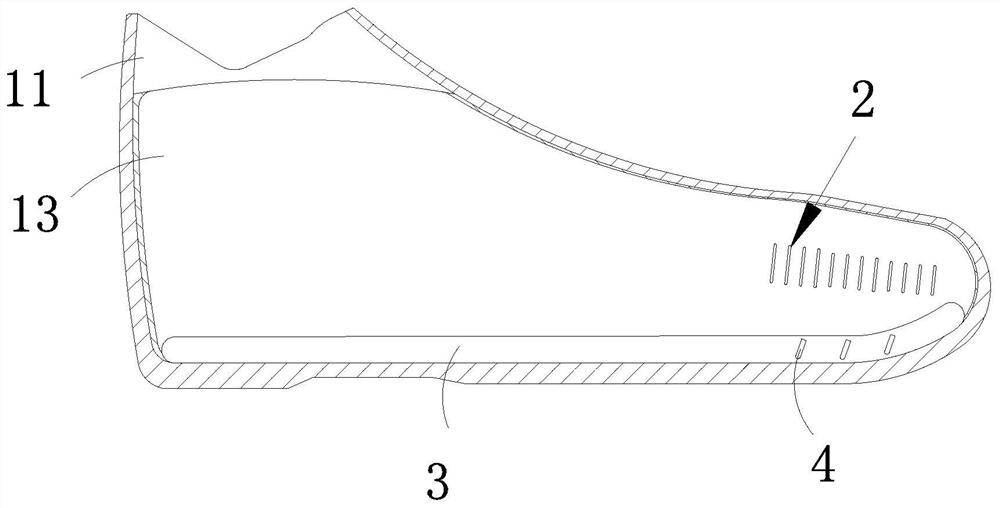

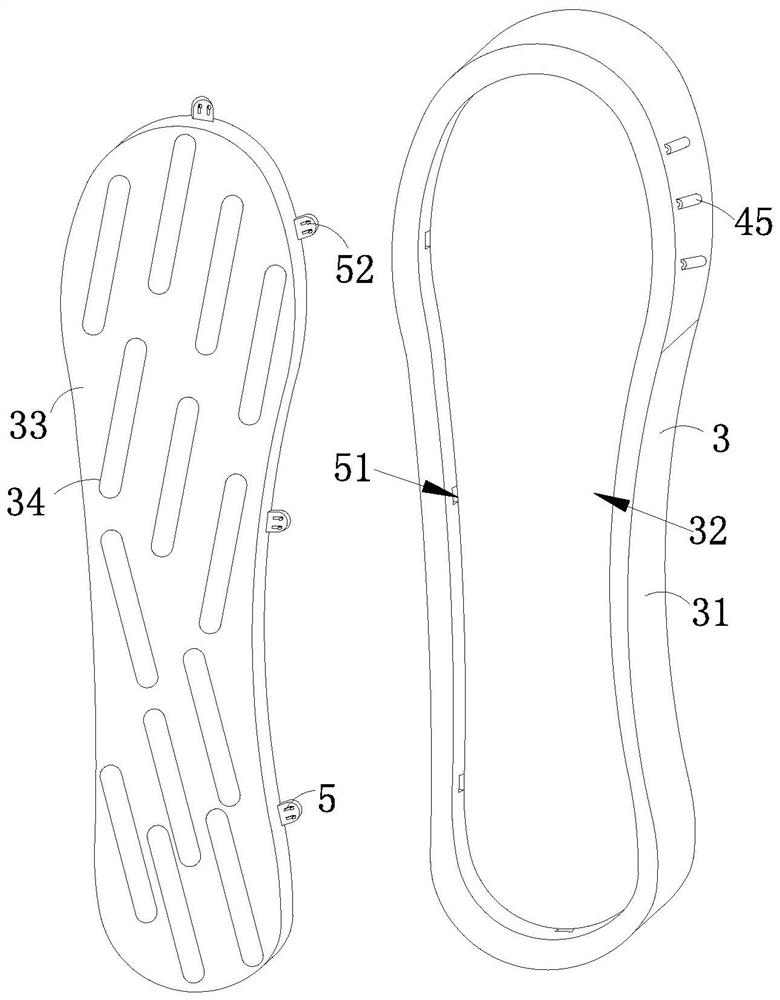

anti-radiation shoes

The present invention relates to the field of shoes, specifically radiation-proof shoes, including a main body, a heat sink, a sweat-absorbing insole, an exhaust mechanism and a limit mechanism. During walking, the soles of the pregnant women’s feet slide on the surface of the sweat-absorbing insole, and the sweat-absorbing salt strips on the surface of the sweat-absorbing insoles rub against the soles of the feet, so that the sweat-absorbing salt strips can absorb the sweat from the soles of the pregnant women’s feet; When the sole of the foot squeezes the exhaust mechanism, the exhaust mechanism is compressed, the gas inside the exhaust mechanism is discharged from one end of the main body, and the gas inside the main body is discharged from the exhaust groove, and when the pregnant woman's sole is lifted upwards , the exhaust mechanism expands and pushes the sweat-absorbing insole upwards slightly to increase the softness of the sweat-absorbing insole and prevent the sweat-absorbing insole from being close to the inside of the main body. The external air enters the inside of the main body through the exhaust groove to increase the circulation of the air inside the main body.

Owner:惠州市杨阳鞋业有限公司

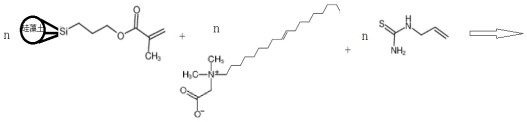

A kind of preparation method of low burning residue betaine hydrochloride co-producing sodium fluorosilicate

ActiveCN112174843BAct as a filter aidReduce the amount of ignition residueOrganic compound preparationOther chemical processesBetaine HydrochlorideSodium fluorosilicate

The invention relates to a preparation method of low-burning residue betaine hydrochloride co-producing sodium fluorosilicate. The industrial by-product fluorosilicic acid is used as a raw material to react with sodium chloride in an amination solution, and the generated hydrogen chloride reacts with sugar beet. Betaine hydrochloride is prepared by combining with alkali, and at the same time, the sodium fluorosilicate product which has a wide range of industrial uses is co-produced, and the comprehensive utilization of sodium chloride is realized. It is of great significance for large-scale production, improving economic benefits, and reducing environmental pressure, and is suitable for industrial production.

Owner:QUZHOU UNIV

Wind and sand prevention distribution box for desert area and wind and sand prevention method

PendingCN114709719AExtended service lifeAbsorb cleanSubstation/switching arrangement casingsDirt cleaningReciprocating motionStructural engineering

The invention relates to the field of power distribution boxes, and particularly discloses a sand-proof power distribution box for desert areas and a sand-proof method, the power distribution box comprises a box body and a box door, a mounting plate is arranged in the box body, electrical elements of the power distribution box are mounted on the mounting plate, and the mounting plate is also provided with a plurality of through holes; a blower and a first driving mechanism are arranged on the box door, and the first driving mechanism is connected with the blower and drives the blower to reciprocate up and down; the distribution box further comprises a dust collector provided with a dust hood and a dust storage box, and the dust hood is embedded in the rear side wall of the box body. Sand dust in the distribution box can be cleaned in time, the service life of the distribution box is prolonged, and potential safety hazards are eliminated.

Owner:山东克曼特新能源科技发展有限公司

An industrial waste gas absorption treatment system

The invention discloses an industrial waste gas absorption treatment system, which comprises a primary absorption device for absorbing hydrogen chloride in the waste gas by using solid particles; The primary absorption device is connected, and the inner wall of the conveying pipeline is provided with a spiral track; the spray absorption device is used to absorb the hydrogen chloride in the exhaust gas by spraying the exhaust gas after dedusting. The hydrogen chloride of the present invention is cleanly absorbed, and the waste gas purification treatment effect is good, and the treatment effect is good; the dust removal rate is high, and the situation of sludge or pipe blockage in the later spraying operation can be effectively avoided.

Owner:KUNSHAN XICHENG MECHANICAL EQUIP CO LTD

Radiation-proof shoes

The invention relates to the field of shoes, in particular to a pair of radiation-proof shoes, wherein the radiation-proof shoe comprises a body, a heat dissipation groove, a sweat absorption insole,an exhaust mechanism and a limiting mechanism. When a pregnant woman uses the body, the foot sole of the pregnant woman makes contact with the sweat absorption insole, and in the walking process of the pregnant woman, the foot sole of the pregnant woman slides on the surface of the sweat absorption insole, the sweat-absorbing micro-salt strips on the surfaces of the sweat-absorbing insoles rub with the soles of feet, so that the sweat-absorbing micro-salt strips can completely absorb sweat on the soles of the feet of the pregnant woman; when the foot sole of a pregnant woman is extruded downwards in the walking process, the foot sole extrudes the exhaust mechanism, the exhaust mechanism is compressed, gas in the exhaust mechanism is exhausted from one end of the main body, gas in the mainbody is exhausted from the exhaust groove, and when the foot sole of the pregnant woman is lifted upwards, the exhaust mechanism expands to push the sweat-absorbing insole to slightly move upwards. The softness of the sweat-absorbing insole is improved, the sweat-absorbing insole is prevented from being tightly attached to the interior of the main body, external air enters the main body through the exhaust grooves, and the circulation of the air in the main body is improved.

Owner:惠州市杨阳鞋业有限公司

A new type of wire feeding machine

The invention relates to a novel shred feeding machine which comprises a machine body, a shred absorbing device and a power supply device. The novel shred feeding machine is characterized in that a feeding port is formed on the machine body; a conveyer belt is arranged above the feeding port; the conveyer belt is fixedly arranged on a machine frame; the machine body is equipped with the power supply device and the shred absorbing device; a shred absorbing port is formed on the shred absorbing device; the shred absorbing device is connected with a shred absorbing pipe; a fast joint is arranged on the shred absorbing pipe; a discharging slot and a manipulator fixer are arranged in the machine body; a manipulator is arranged on the manipulator fixer; a charging barrel can be clamped by the manipulator; a weighting device is also arranged on the machine body; and the weighting device is used for weighting the charging barrel. The novel shred feeding machine disclosed by the invention has the beneficial effects that the tobacco shreds used by each cigarette making machine can be counted and recorded; the problem of material blocking of the shred feeding machine can be effectively prevented; when the shred feeding machine is in fault or is maintained, the shred feeding machine under a working state is wholly and quickly replaced by its standby machine under the condition of no influence on normal downstream process.

Owner:玉溪市新特科技有限公司

A dust removal equipment for cloth printing and dyeing process

ActiveCN110125098BAvoid pollutionAbsorb cleanMechanical cleaningPressure cleaningDust controlWorking environment

The invention discloses a dust removal device for cloth printing and dyeing process, which comprises a casing, a beating part, a dust suction part and a dust removal part. Located outside the casing, the dust removal component includes a dust removal assembly, a cleaning assembly and a drying assembly. The dust removal assembly is located inside the casing, the cleaning assembly is located outside the casing, and the drying assembly is located next to the cleaning assembly. The dust part and the dust removal assembly on the dust removal part are located in the housing, and the housing can provide protection for the entire dust removal working environment from the influence of external dust and prevent secondary pollution to the cloth by dust in the dust removal process. The invention beats the cloth through the beating part, then vacuums the beating cloth through the dust suction part, and cleans the cylinder through the cleaning component and the drying component without stopping the machine, so as to improve the dust removal efficiency.

Owner:绍兴金祥惠纺织印染有限公司

Collection device for oil slick in sewage pond

PendingCN110745906AReduce processing difficultyIn line with the concept of environmental protectionFatty/oily/floating substances removal devicesLiquid separationWater dischargeSewage

The invention discloses a collection device for oil slick in a sewage pond, and belongs to the field of sewage treatment. The device includes an oil-water separation tank, the top of the oil-water separation tank is provided with an oil flow groove, the interior of the oil-water separation tank is provided with a secondary oil-water separation zone and a primary oil-water separation zone in the left-right direction, the upper part of the interior of the primary oil-water separation zone is provided with a rotating disc, the oil outlet end of the oil flow groove is connected to the secondary oil-water separation zone, and the other end of the oil flow groove is provided with a rectangular groove for placing two sides of the rotating disc; two oil scraping sheets are obliquely symmetricallyarranged on two sides of the rotating disc, one end of each oil scraping sheet abuts against the end surface of one side of the rotating disc, and the other end of each oil scraping sheet faces downwards to the bottom of the oil flow groove; and the bottom of the secondary oil-water separation zone is provided with a secondary water discharge opening and an oil discharge opening, the bottom of theprimary oil-water separation zone is provided with a primary water discharge opening, and the primary oil-water separation zone is connected to an oil suction floating mechanism through a pipeline. By adopting the technical solution of the invention, oil-water complete separation can be achieved, dirty oil can be collected and treated separately, and the difficulty of sewage treatment can be reduced.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Laboratory nano material gas incineration absorbing apparatus

InactiveCN102824811BUrgent need to meet safe emissions requirementsSolve a major technical problem in adsorption treatmentDispersed particle separationIncinerator apparatusHazardous substanceColloid

The invention provides a laboratory nano material gas incineration absorbing apparatus which is characterized in that gas containing a nano material, which is collected from a nano laboratory, is conveyed to a liquating cabin through a collected gas input port so as to be mixed with compressed air input by another path under the stirring of a floating ball, and the mixture is diluted and then conveyed into an incineration bent pipe passage in an ultra-temperature furnace chamber; and the nano material gas subjected to high-temperature burning and incineration can be used for incinerating and digesting the whole or major nano material; after incineration, even if residual gas containing harmful substances enters into an absorbing rubber cabin and performs liquid-gas reverse exchange with preheated gel liquid under the driving of a colloid pump, an air pump drives clean gas to be exhausted through a dry grid, and the harmful substances left through exchange are adsorbed to a gel pool by gel so as to be accumulated, stored and recondensed for recovery processing. The laboratory nano material gas incineration absorbing apparatus provided by the invention has the beneficial effects that the technical problem of adsorption processing of laboratory nano material exhaust gas is solved; and special equipment which is safe, convenient, rapid and effective and can be used for thoroughly and cleanly adsorbing and processing laboratory nano material gas is provided.

Owner:TIANJIN HOPE IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com