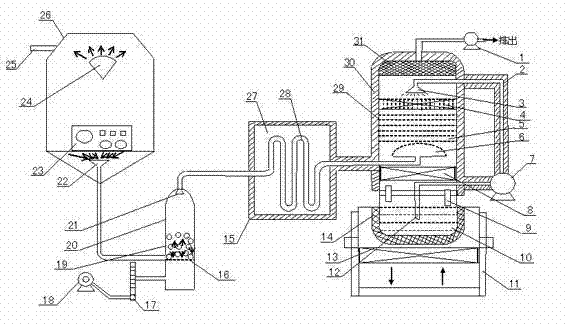

Laboratory nano material gas incineration absorbing apparatus

A technology of nanomaterials and absorption equipment, applied in the field of laboratory nanomaterial gas incineration absorption equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020]Before using a kind of laboratory nano material gas incineration absorption equipment of the present invention to dispose, should at first understand the nano material physical and chemical properties used in the experiment so as to adopt which temperature, add suitable gel adsorption liquid in the gel pool 10, advance in advance Check and connect each pipeline to make it sealed. When starting the operation, first turn on the power supply of the heater 13 under the ultra-high temperature furnace chamber 27 and the gel pool 10. After a period of pre-heating, the incineration elbow 28 reaches the required high temperature environment and freezes. The fluidity of the gel adsorption liquid in the glue pool 10 meets the requirements, and now the upper heating fence 4, the lower heating fence 8, and the power supply of the colloid pump 7 on the absorption glue cabin 29 can be started to allow the gel adsorption liquid to spray in the absorption glue cabin 29. Shower flow cycle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com