A kind of preparation method of low burning residue betaine hydrochloride co-producing sodium fluorosilicate

A technology of burning residue and sodium fluorosilicate is applied in the field of preparation of low-burning residue betaine hydrochloride co-producing sodium fluorosilicate, which can solve the problem of high energy consumption, low burning residue and difficulty in obtaining low-burning residues. Burning residue products and other problems, to achieve the effect of increasing the chelating capacity and reducing the amount of burning residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

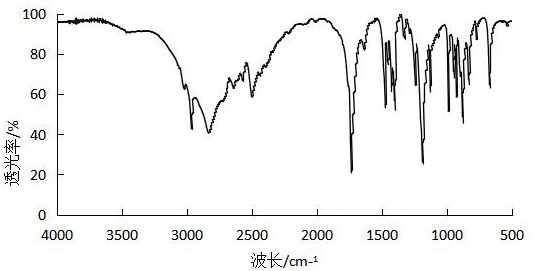

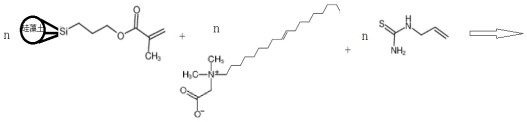

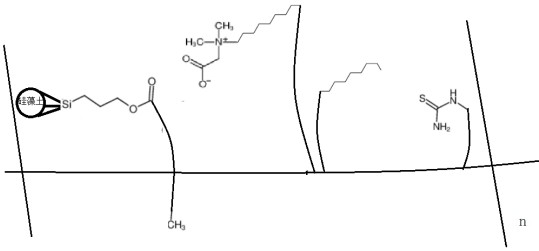

Image

Examples

Embodiment 1

[0036] The amination solution of 1000g sodium synthesis betaine was put into the reactor, wherein the betaine mass percentage content was 30%, the sodium chloride mass percentage content was 15%, and 462.4g of fluorosilicic acid solution (the mass of fluorosilicic acid) was added dropwise. The percentage content is 35%, the percentage content of hydrofluoric acid is 0.5%), the reaction temperature is controlled at 5 °C, the reaction is stirred for 5 h, filtered, the filter cake is washed with water and then dried to obtain sodium fluorosilicate, the washing liquid and the filtrate are combined, add 19.5g calcium dihydrate compound was stirred for 2 hours, insoluble matter was removed by filtration, 9g oxalic acid dihydrate was added to the filtrate, the reaction temperature was controlled at 90 °C, the reaction was stirred for 0.5 hours, filtered, and the filter cake was washed with water, and the filtrate and washings were combined, Heat to 95°C, dropwise add 10 g of a hydroge...

Embodiment 2

[0041] The amination solution of 1000g sodium synthesis betaine was put into the reactor, wherein the mass percentage content of betaine was 35%, the mass percentage content of sodium chloride was 17.5%, and 616.4g of fluorosilicic acid solution (the mass of fluorosilicic acid) was added dropwise. The percentage content is 35%, the percentage content of hydrofluoric acid is 1%), the reaction temperature is controlled to 40 ° C, the reaction is stirred for 1 h, filtered, the filter cake is washed with water and then dried to obtain sodium fluorosilicate, the washing liquid and the filtrate are combined, add 35g calcium hydroxide was stirred for 0.5 h, insoluble matter was removed by filtration, 6 g of oxalic acid dihydrate was added to the filtrate, the reaction temperature was controlled at 60 °C, stirred for 1.5 h, filtered, and the filter cake was washed with water, the filtrate and washings were combined, and heated to 100 °C ℃, dropwise add 20 g of hydrogen peroxide solutio...

Embodiment 3

[0046] The amination solution of 1000g sodium synthesis betaine was put into the reactor, wherein the betaine mass percentage content was 32%, the sodium chloride mass percentage content was 16%, and 520g fluorosilicic acid solution (the mass percentage of fluorosilicic acid) was added dropwise. The content is 38%, the percentage content of hydrofluoric acid is 0.75%), the reaction temperature is controlled at 30 ° C, the reaction is stirred for 3 h, filtered, the filter cake is washed with water and then dried to obtain sodium fluorosilicate, the washing liquid and the filtrate are combined, and 26.5 g calcium dihydrate compound, stirred for 1.5 h, filtered to remove insoluble matter, added 8 g of oxalic acid dihydrate to the filtrate, controlled the reaction temperature to 85 °C, stirred for 1 h, filtered, and washed the filter cake with water, combined the filtrate and washing liquid, and heated to 98 ℃, dropwise add 18 g of hydrogen peroxide solution with a content of 25% b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com