A method for treating residual sludge after biological treatment of wastewater

A treatment method and biological treatment technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high cost hindering engineering application, increasing the solid content of mud cake after dehydration, etc. , to reduce secondary pollution, increase permeability, and increase particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

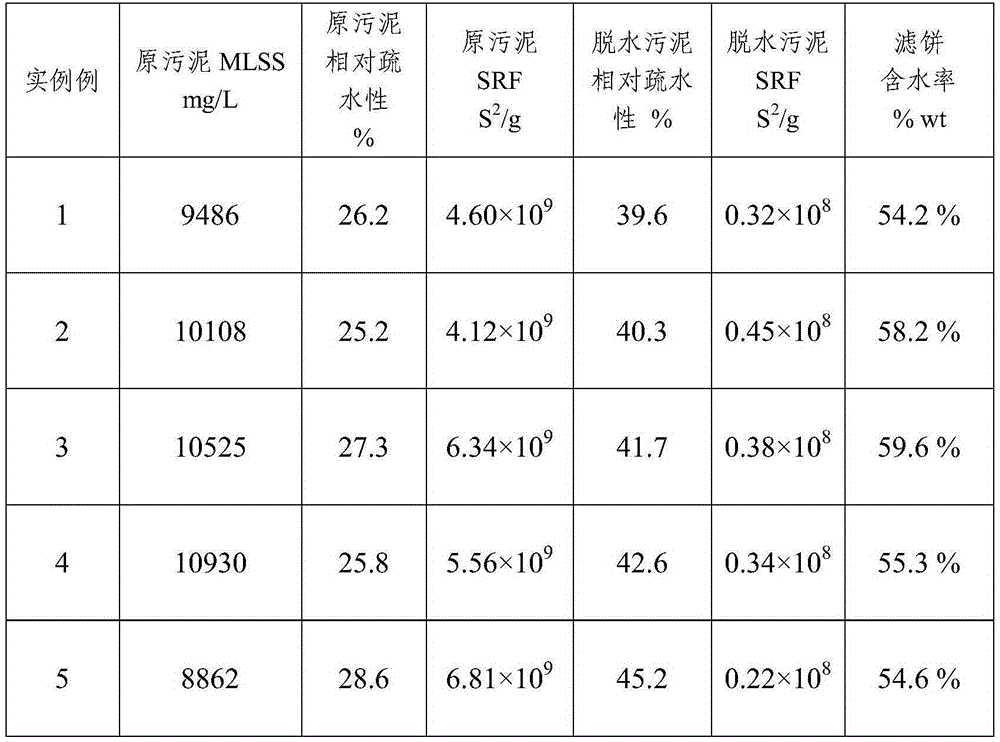

Examples

Embodiment 1

[0023] (1), the remaining sludge of urban sewage is prepared into a mixed solution with a suspended solids concentration of 9486mg / L, 500ml is taken and added to the reaction tank, under rapid stirring at 100 rpm, the pH is adjusted to 2.0 with hydrochloric acid;

[0024] (2), the mixed solution after step (1) is heated to 50 DEG C, add ferrous sulfate solution, sodium persulfate solution or potassium persulfate solution and industrial fly ash, stir and react with 40 rpm for 4 hours; Described ferrous sulfate solution, mass-volume concentration is 10%; Sodium persulfate solution or potassium persulfate solution mass-volume concentration is 10%; The processing method of industrial fly ash is: dry at 105 ℃, pass 200 Mesh sieve, remove block and slag, dry for subsequent use; Wherein, ferrous sulfate 0.43g in ferrous sulfate solution, sodium persulfate 2.31g in sodium persulfate solution, industrial fly ash 1.58g.

[0025] (3) Adjust the pH to 9.0 with sodium hydroxide solution, d...

Embodiment 2

[0033] (1), the remaining sludge of urban sewage is prepared into a mixed solution with a suspended solid concentration of 10108mg / L, 500ml is taken and added to the reaction tank, and under rapid stirring at 110 rpm, the pH is adjusted to 2.0 with hydrochloric acid;

[0034] (2), the mixed solution treated in step (1) is heated to 60° C., adding ferrous sulfate solution, sodium persulfate solution or potassium persulfate solution and industrial fly ash, and stirring and reacting for 5 hours at 50 rpm; Described ferrous sulfate solution, mass-volume concentration is 8%; Sodium persulfate solution or potassium persulfate solution mass-volume concentration is 11%; The processing method of industrial fly ash is: dry at 90 ℃, pass 200 Mesh sieve, remove lumps and slag, dry for subsequent use; wherein, 0.465g of ferrous sulfate in ferrous sulfate solution, 2.4g of sodium persulfate in sodium persulfate solution, and 1.6g of industrial fly ash.

[0035] (3) Calcium hydroxide solutio...

Embodiment 3

[0038] (1) Prepare the mixed liquor with a suspended solids concentration of 10525mg / L from the remaining sludge of urban sewage, take 500ml and add it to the reaction tank, stir rapidly at 100r / min, and adjust the pH to 3.0 with hydrochloric acid;

[0039] (2), the mixed solution treated in step (1) is heated to 58° C., ferrous sulfate solution, sodium persulfate solution or potassium persulfate solution and industrial fly ash are added, and the reaction is stirred and reacted at 50 rpm for 6 hours; Described ferrous sulfate solution, mass-volume concentration is 10%; Sodium persulfate solution or potassium persulfate solution mass-volume concentration is 12%; The processing method of industrial fly ash is: dry at 90 ℃, pass 200 Mesh sieve, remove block and slag, dry for subsequent use; Wherein, ferrous sulfate 0.41 in ferrous sulfate solution, potassium persulfate 2.3g in potassium persulfate solution, industrial fly ash 1.7g.

[0040] (3) Use sodium hydroxide solution to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com