Municipal sludge and engineering slurry co-processing device and co-processing method thereof

A municipal sludge and co-processing technology, applied in sludge treatment, water/sludge/sewage treatment, grain treatment, etc., can solve the problem that the municipal sludge and engineering sludge cannot be fully mixed, affect the stability of the ball mill, and affect the work. Environmental quality and other issues, to achieve the effect of improving filter press dehydration performance, improving the quality of the working environment, and reducing work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

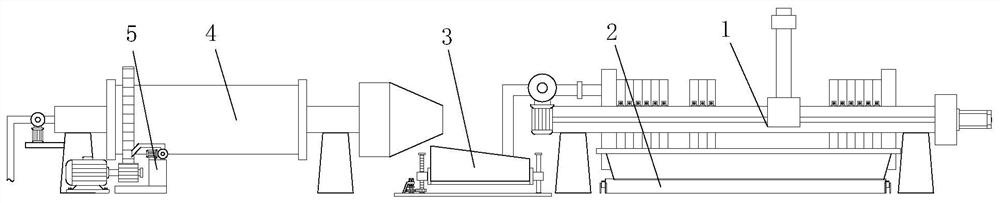

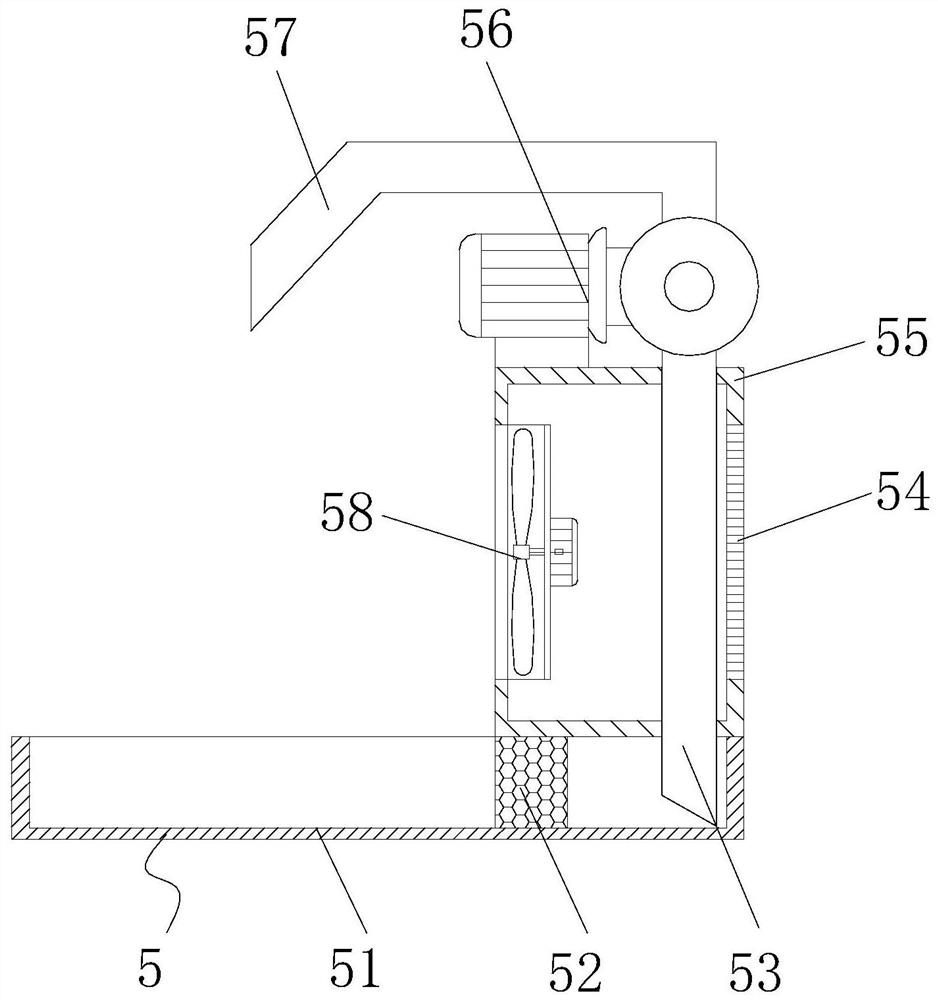

[0038] see Figure 1-8 , the present invention provides the following technical solutions: a municipal sludge and engineering mud co-processing device, comprising a ball mill 4, a plate and frame filter press 1 is arranged on one side of the ball mill 4, and a convenient cooling assembly 5 is arranged on the bottom end of the ball mill 4, The convenient cooling assembly 5 includes a collection tank 51, a fiber filter screen 52, a guide pipe 53, a mounting frame 55, a water pump 56 and a spray pipe 57, wherein the bottom end of the ball mill 4 is provided with a collection tank 51, and the inside of the collection tank 51 is provided with There is a fiber filter screen 52, the upper end of the collection tank 51 is provided with a mounting frame 55, the upper end of the mounting frame 55 is provided with a water pump 56, the bottom end of the water pump 56 is provided with a guide tube 53, and the upper end of the water pump 56 is provided with a spray pipe 57, During the worki...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is: further; an adjustment transfer assembly 3 is provided between the ball mill 4 and the plate and frame filter press 1, and the adjustment transfer assembly 3 includes a guide column 31, a dump box 32, and a screw rod 33 , stepping motor 34, driving gear 35, driving gear 35, mounting plate 37 and base plate 38, wherein, one side of ball mill 4 is provided with base plate 38, and one side of the upper end of base plate 38 is provided with stepping motor 34, step The output end of the motor 34 is provided with a driving gear 35, and one side of the driving gear 35 is provided with a screw mandrel 33, and the surface of the screw mandrel 33 is provided with a driven gear 36 corresponding to the driving gear 35, and the upper end of the base plate 38 is far away from the screw mandrel 33. One side is provided with a guide post 31 , and a mounting plate 37 is provided between the guide post 31 and the screw mandrel 33...

Embodiment 3

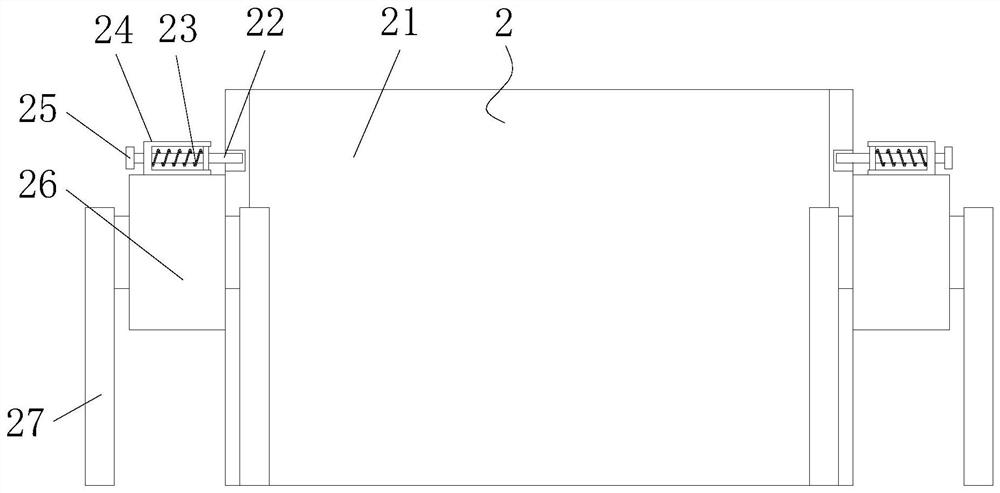

[0045] The difference between this embodiment and Embodiment 1 is: further; the bottom end of the plate and frame filter press 1 is provided with a mud cake take-out assembly 2, and the mud cake take-out assembly 2 includes a retrieving box 21, a limit insertion rod 22, a limit Position spring 23, fixed frame 24, pull handle 25, transmission belt 26, support frame 27 and guide device 28, wherein, the bottom end of plate and frame filter press 1 is symmetrically provided with support frame 27, and the upper end of support frame 27 is provided with transmission belt 26 , the surface of the transmission belt 26 is provided with a fixed frame 24, the interior of the fixed frame 24 is provided with a limit insertion rod 22, the surface of the limit insertion rod 22 is socketed with a limit spring 23, and one side of the limit insertion rod 22 is provided with a pull handle 25. A retrieving box 21 is arranged between the transmission belts 26, and guide devices 28 are provided on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com