Method for removing various organic compounds in sodium aluminate solution in aluminum oxide production

A technology of organic compounds and alumina, which is applied to the preparation of aluminum compounds, alkali metal aluminates/aluminum oxide/aluminum hydroxide, chemical instruments and methods, etc. It can solve problems such as poor removal effect, large expenditure, and difficult operation , to achieve the effect of low cost, small investment and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

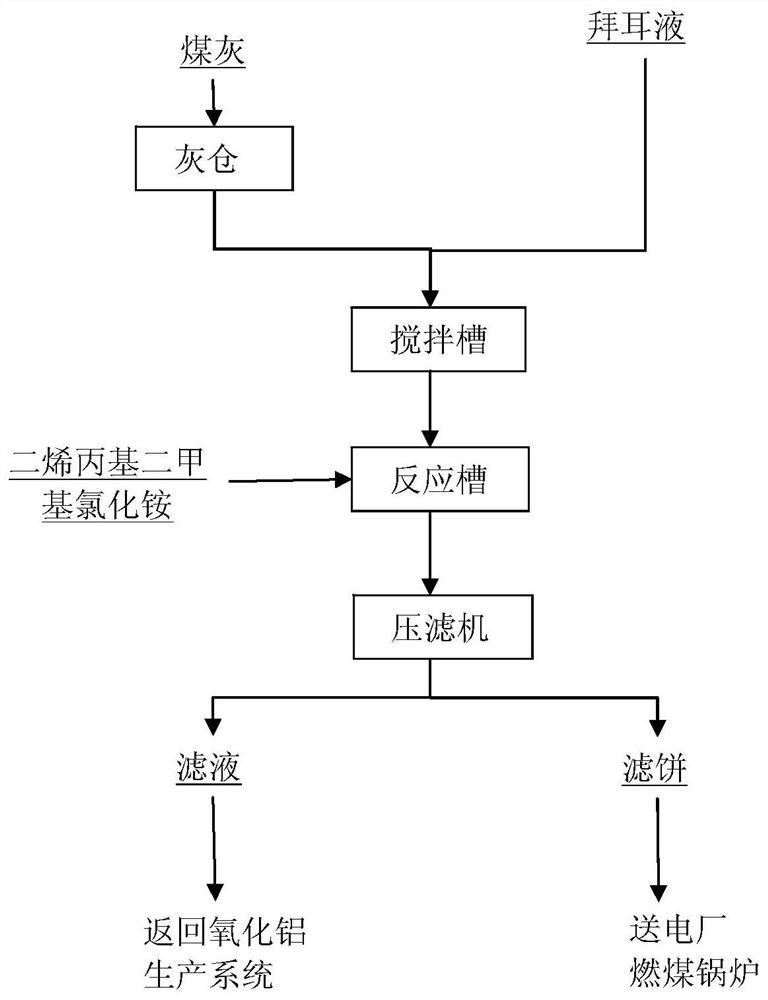

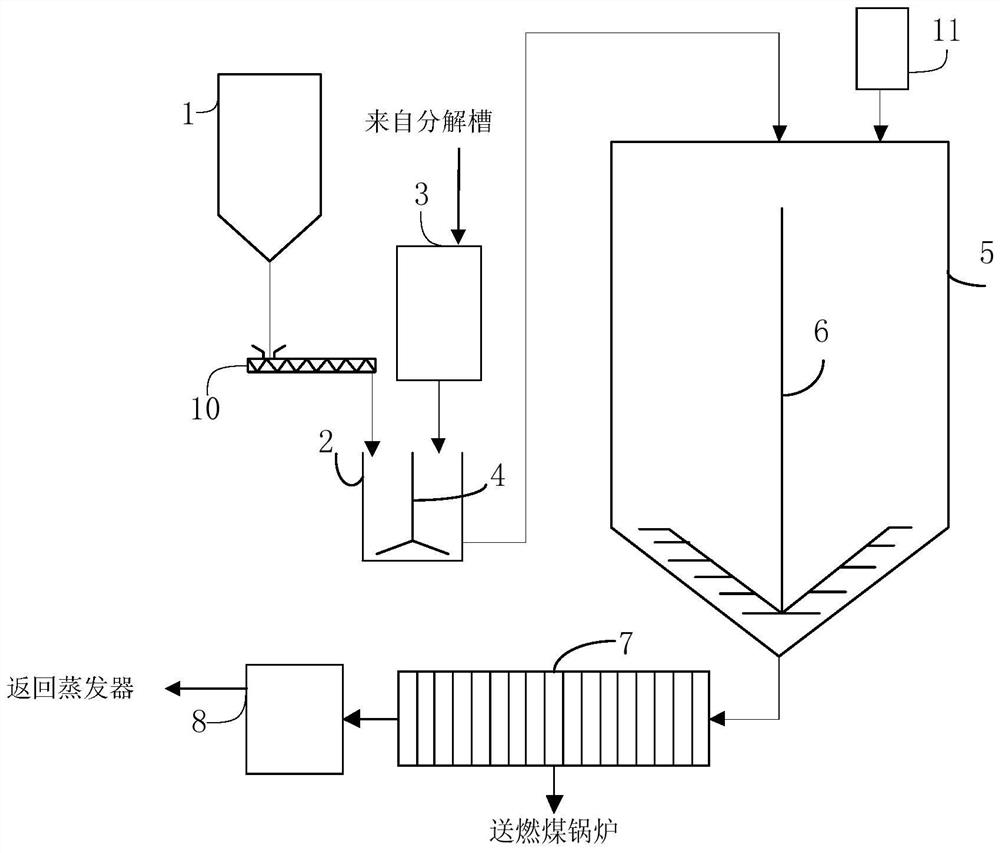

[0038] The method for removing various organic compounds in sodium aluminate solution in alumina production includes the following steps: adding coal ash into Bayer solution, mixing uniformly, and reacting at a temperature of 50°C for 6 hours, then filtering, The filtrate is sent back to the evaporator of the alumina production system for evaporation and concentration, and then transferred to the dissolution process for recycling; the filter cake is a coal ash filter cake with organic matter with low moisture content, and is directly sent to the coal-fired boilers of the power plant for other coal-fired devices. Fuel utilization, safety and environmental protection;

[0039] It is stated that the Bayer solution is the sodium aluminate solution obtained after precipitating aluminum hydroxide through the decomposition tank in the alumina production system;

[0040] It is said that the coal ash is the by-product ash powder produced by the gas generator;

[0041] The added amount...

Embodiment 2

[0043] A method for removing various organic compounds in a sodium aluminate solution in alumina production, comprising the following steps: firstly pre-treating the coal ash with nitric acid before use, specifically adding nitric acid to the coal ash to mix evenly, and then filtering The pretreated coal ash can be obtained by drying; the concentration of nitric acid is 0.1 mol / L, and the solid content of the feed liquid obtained by pretreatment is 200 g / L; the pretreated coal ash is added to the Bayer solution and mixed evenly Then, under the condition of temperature of 50 °C, after standing for 6 hours, the filtrate was filtered, and the filtrate was sent back to the evaporator of the alumina production system for evaporation and concentration, and then transferred to the dissolution process for recycling; the filter cake was coal ash with organic matter. The filter cake, with low moisture content, can be directly sent to the coal-fired boilers of power plants and other coal-...

Embodiment 3

[0048] A method for removing various organic compounds in a sodium aluminate solution in alumina production, comprising the following steps: firstly pre-treating the coal ash with nitric acid before use, specifically adding nitric acid to the coal ash to mix evenly, and then filtering The pretreated coal ash can be obtained by drying; the concentration of nitric acid is 0.1 mol / L, and the solid content of the feed liquid obtained by pretreatment is 200 g / L; the pretreated coal ash is added to the Bayer solution and mixed evenly Then, 50ppm of diallyl dimethyl ammonium chloride was added, and after mixing, the reaction was allowed to stand for 6 hours at a temperature of 50 °C, and then filtered, and the filtrate was returned to the alumina production system for recycling. The filter cake was used as The fuel is sent to other coal-fired devices in the power plant;

[0049] It is stated that the Bayer solution is the sodium aluminate solution obtained after precipitating aluminu...

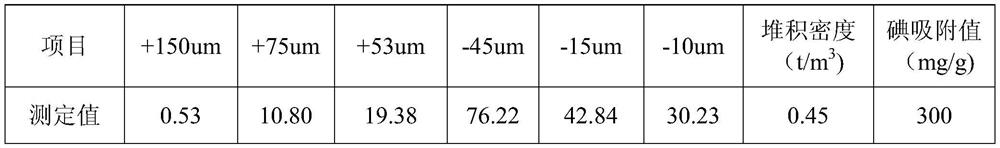

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com