Collection device for oil slick in sewage pond

A technology for collection devices and sewage pools, which is applied in water/sewage treatment, grease/oily substance/floating matter removal devices, water/sewage treatment equipment, etc., which can solve the problems of increased energy consumption, weak automation, and failure to achieve oily water Separation and other issues to achieve the effect of reducing processing difficulty, automation and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

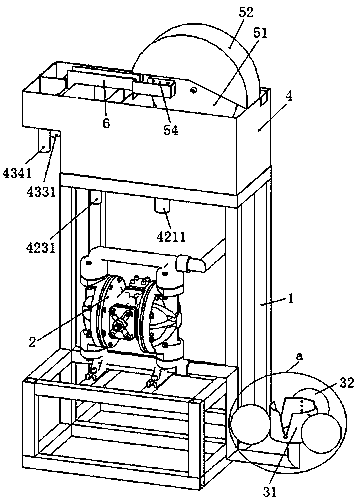

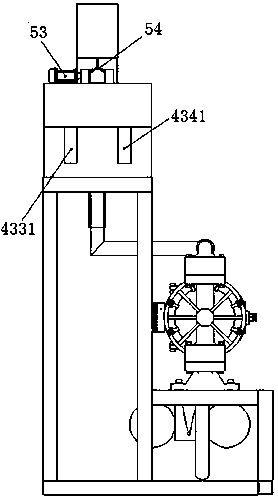

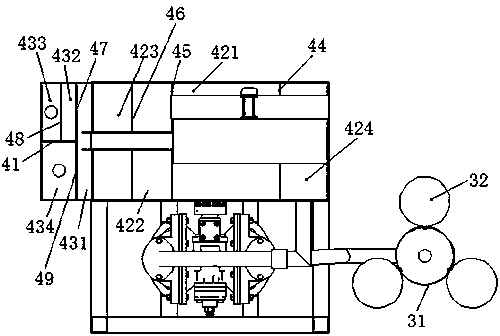

[0036] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a floating oil collection device for a sewage tank in this embodiment, comprising a bracket 1 and an oil-water separation box 4 arranged on the bracket 1, the top of the oil-water separation box 4 is provided with an oil flow tank 6, and the inside of the oil-water separation box 4 is arranged along the left and right direction. A secondary oil-water separation area and a primary oil-water separation area are provided in sequence, wherein an oil scraping rotating mechanism is arranged on the upper part inside the primary oil-water separating area, and the oil scraping rotating mechanism includes a turntable 51, a turntable cover 52 arranged on the top of the turntable 51 and a drive turntable 51 rotates the servo motor 53, one end of the above-mentioned oil flow groove 6 extends to the left to form an oil outlet connected to the above-mentioned secondary oil-water separation area, and the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com