Carriage excess material sweeping and collecting device

A collection device and carriage technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of poor adsorption effect, unclean cleaning, high adsorption noise, etc., and achieve better separation and sedimentation effect and adsorption effect. Excellent effect of reducing energy consumption of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

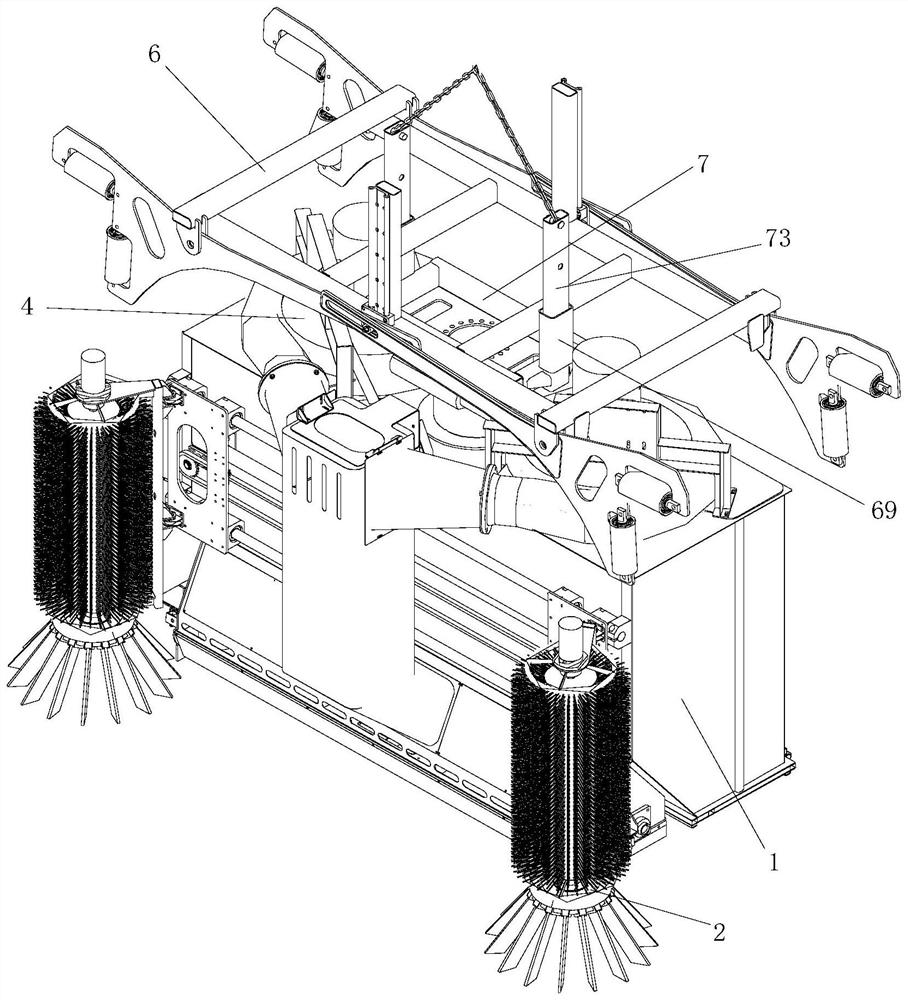

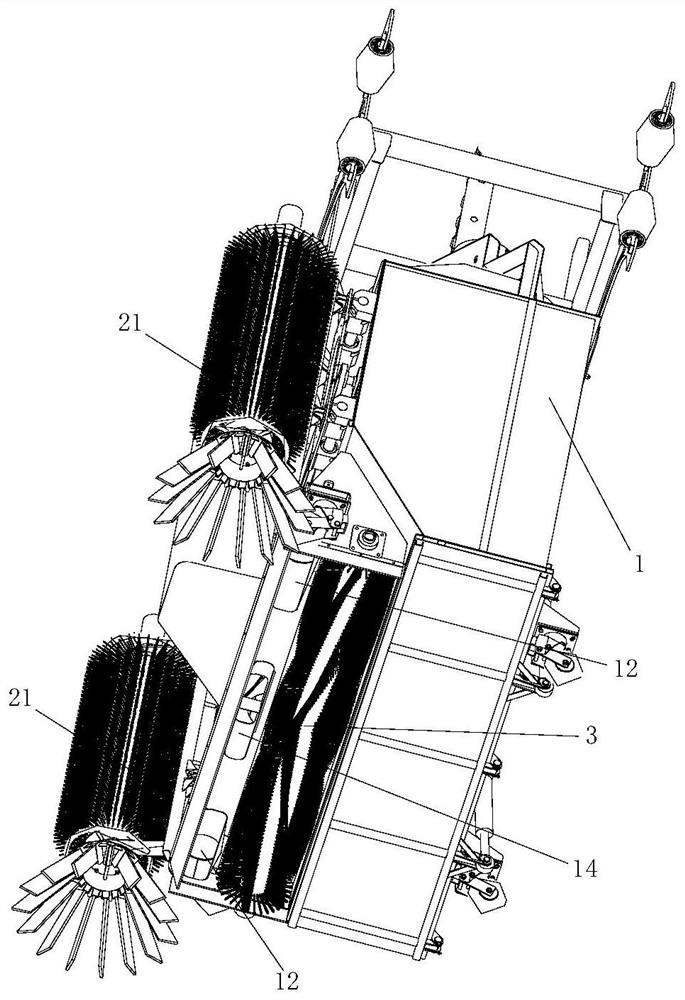

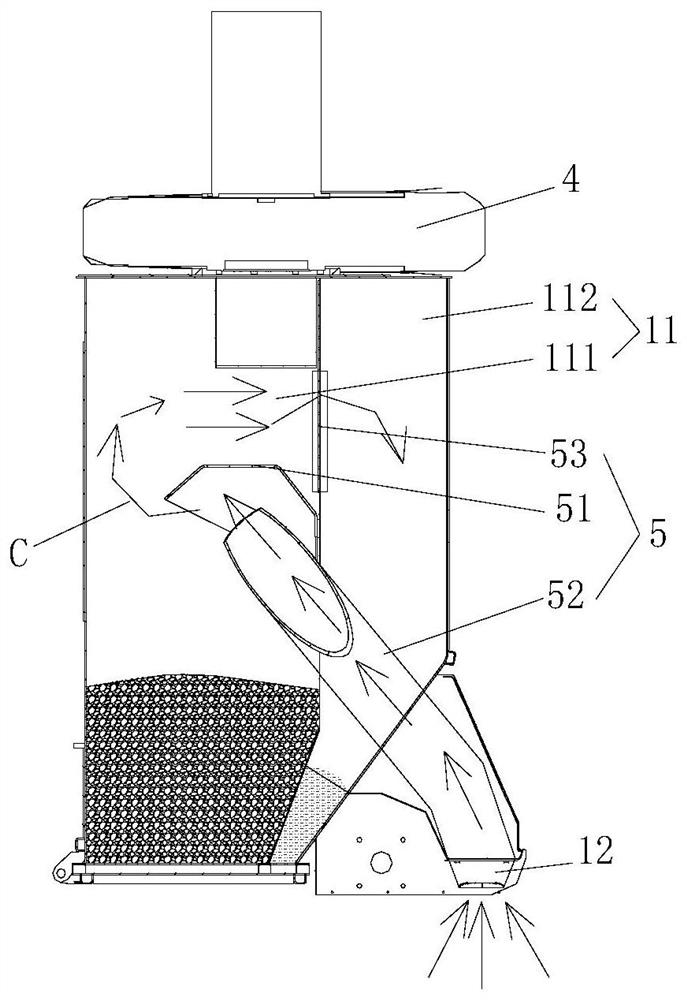

[0043] Such as Figure 1 to Figure 12 As shown, the present invention provides a cleaning and collecting device for car residues, comprising a box body 1, on which more than one vertical brush mechanism 2 and a horizontal brush mechanism 3 for cleaning residues are provided, and the bottom of the box body 1 is provided with There is a suction nozzle 12, and the box body 1 is also provided with an adsorption mechanism 4. The box body 1 is provided with a collection bin 11. In this embodiment, the bottom of the box body 1 is provided with a discharge door at the collection bin 11. A filter mechanism 5 is provided in the collection bin 11, and the adsorption mechanism 4 communicates with the suction nozzle 12 through the collection bin 11, and is used for negative pressure adsorption so that the residue inhaled from the suction nozzle 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com