Tubular pump-free suction mechanism

An absorption mechanism and tube-type technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor foundation for popularization and application, inapplicability of small-caliber barrels, high suction force requirements, etc., to achieve Reasonable layout, good environmental protection benefits, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

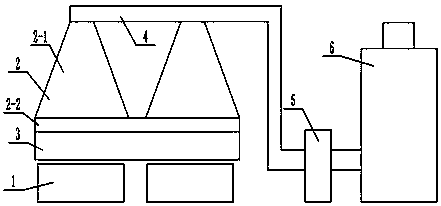

[0009] Depend on figure 1 Known, the present invention a kind of tube-type non-pump absorption mechanism, is made up of pickling tank 1, square cone body cover 2, drooping soft board 3, mist suction tube 4, anti-corrosion induced draft fan 5, treatment tower 6, pickling tank 1 is installed On the ground, the square cone body cover 2 is arranged directly above the pickling tank 1, and the mist suction pipe 4 is arranged on the top of the square cone body cover 2 and is connected thereto. The other end is connected to the processing tower 6. The square cone cover 2 is composed of a mist guide slant plate 2-1 and a fog storage plate 2-2. The square pyramidal structure, the fog storage plate 2-2 is arranged on the lower four sides of the square pyramidal structure, the outer side of the fog storage plate 2-2 is provided with a drooping soft board 3, and the two square pyramidal body covers 2 are connected in series through the mist suction pipe 4, and the plurality of square cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com