Road repair sundry and dust removal device and cleaning trolley

A dust collection device and sundry technology, applied in the direction of road surface cleaning, combined devices, cleaning methods, etc., can solve the problems of dust, low cleaning efficiency, dust cleaning is not clean, etc., to achieve the effect of solving impact and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

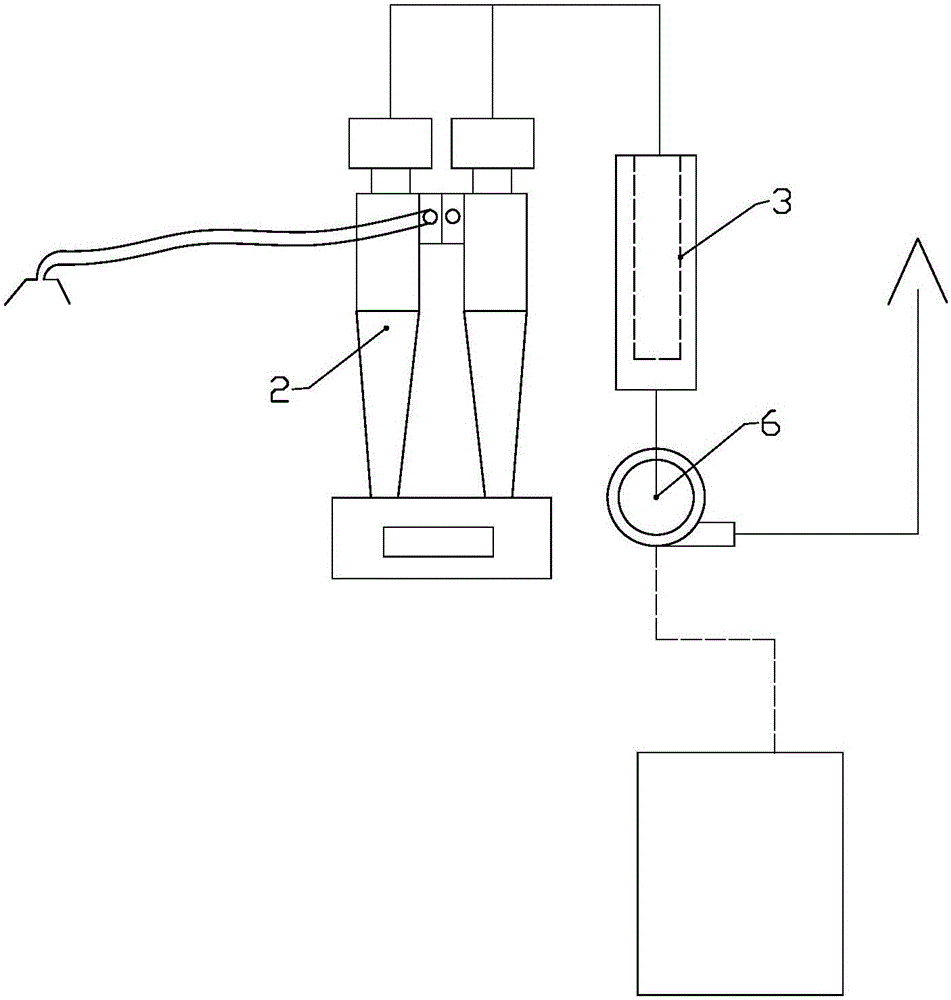

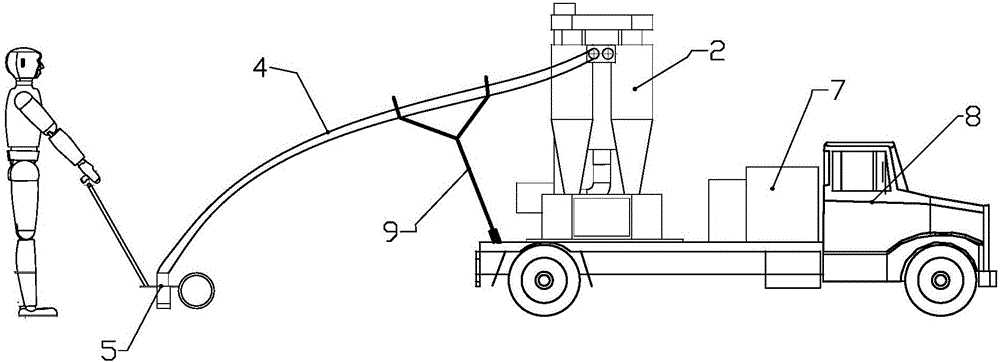

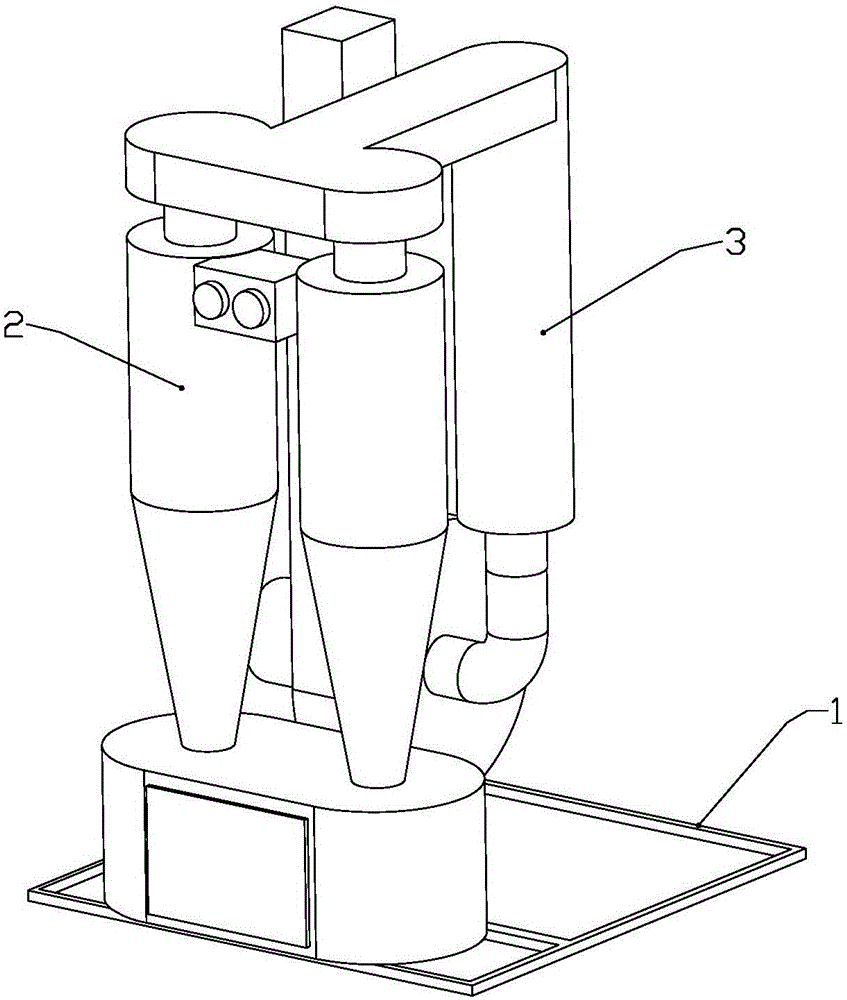

[0032] Such as Figure 1 to Figure 9 As shown, in view of the existing defects, the protection subject of the present invention is as follows:

[0033] The development is a cleaning device and cleaning vehicle for repairing road debris, especially for removing stones, dust and other debris on the road surface after milling by a milling machine, meeting the requirements for paving new asphalt on the road surface, and a mechanized construction method , Improve construction efficiency and reduce labor consumption.

[0034] The basic principle is that firstly, it is aimed at the uneven surface of the milling base layer, and secondly, the larger particles such as gravel generated during the milling process are cleaned. It is difficult for the traditional sweeper to complete the above work. In this embodiment Equipped with high-power dust collection equipment for operation, the operation efficiency is high and the effect is good.

[0035] Based on the above description, the specific stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com