Gear scrap cleaning device

A technology for cleaning devices and gears, used in gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of scattered waste, multiple wastes, and difficulty in cleaning iron filings, and achieve clean adsorption. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

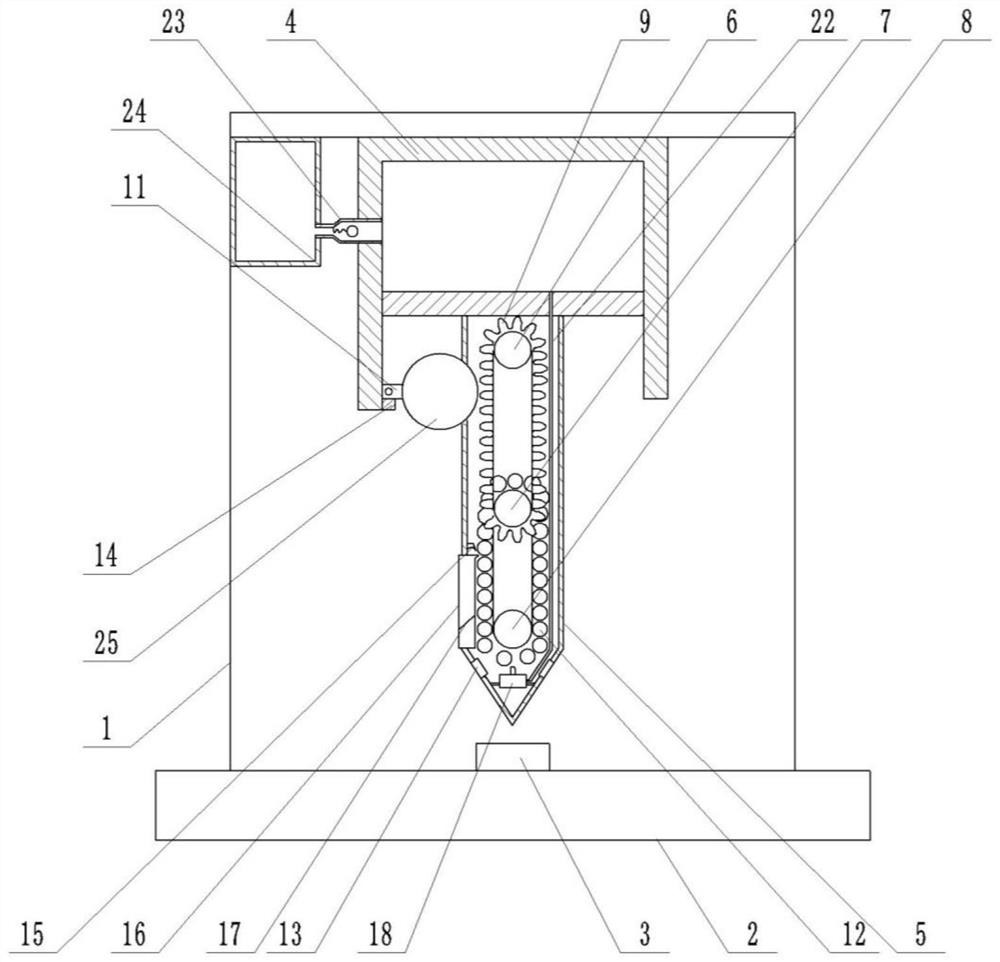

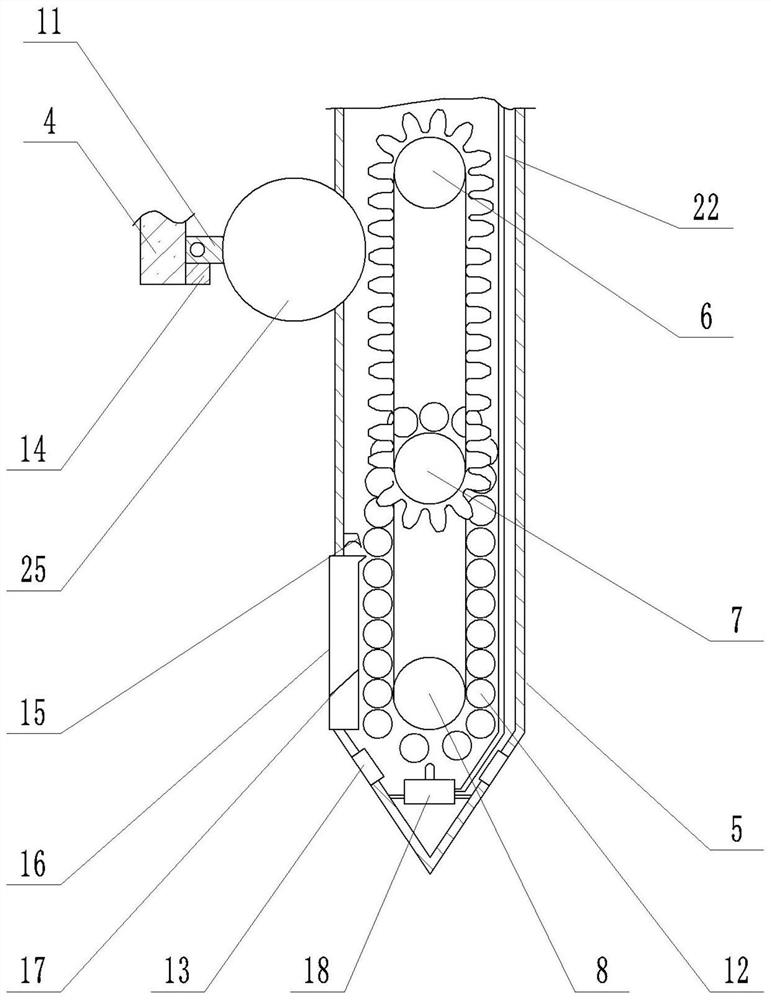

[0030] Example 1 is basically as attached Figure 1-4 shown:

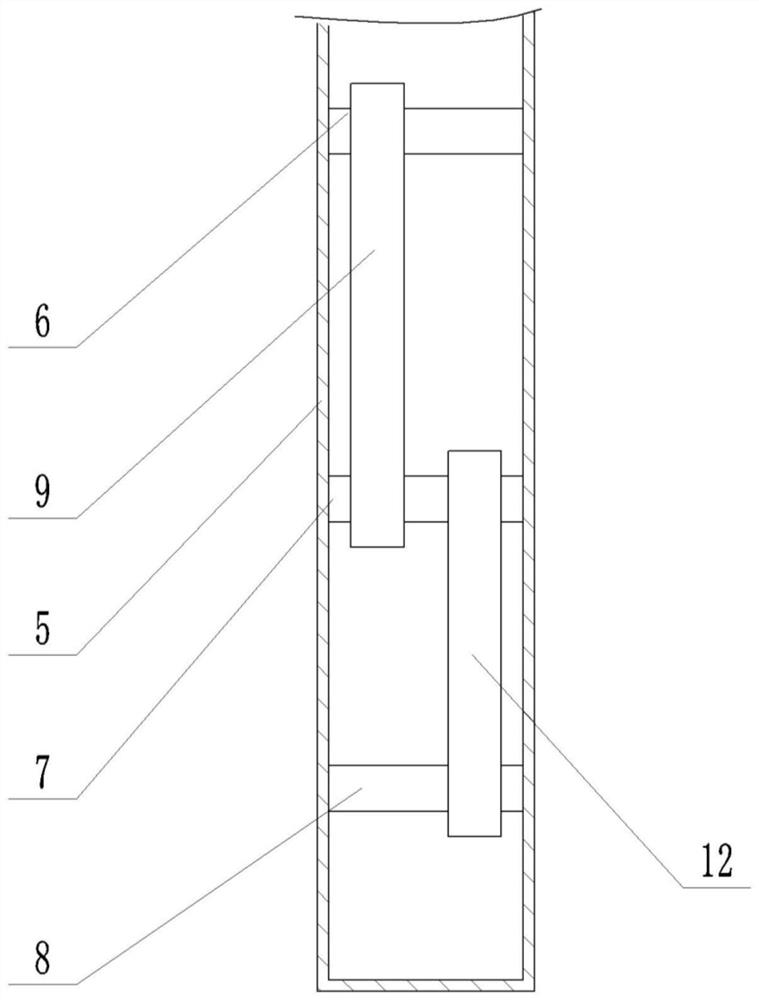

[0031] A gear scrap cleaning device, comprising a frame 1, a worktable 2 is arranged on the frame 1, a hydraulic cylinder 4 is arranged on the frame 1, a cutter 5 is installed on the piston of the hydraulic cylinder 4, and the cutter 5 is arranged on the There is a waste cleaning device; the worktable 2 is arranged under the cutter 5, the worktable 2 is used to store the gear workpiece 3, and the hydraulic cylinder 4 is used to drive the cutter 5 to move up and down, thereby completing the cutting of the gear workpiece 3.

[0032] The waste cleaning device includes a first rotating shaft 6, a second rotating shaft 7, a third rotating shaft 8 and a gear 25. The first rotating shaft 6, the second rotating shaft 7 and the third rotating shaft 8 are rotatably arranged on the side walls at both ends of the cutter 5, The first rotating shaft 6 and the second rotating shaft 7 are connected with a chain 9, the cutter 5 is...

Embodiment 2

[0049] The difference between this embodiment 2 and the embodiment 1 is that, as shown in the appendix Image 6 shown:

[0050] Also includes a storage mechanism, the storage mechanism includes a storage rack 26 and a moisture monitoring assembly, the storage rack 26 is sequentially provided with a storage frame 27 for storing the gear workpiece 3 from top to bottom,

[0051] The moisture monitoring component is located at the top of the storage rack 26. The moisture monitoring component includes a box body 28, an oil pot 29, a water absorption drying box 30, a load-bearing plate 31, a pressure sensor 34 and a single-chip microcomputer. On the top, the water absorbing drying box 30 is slidably arranged on the box body 28, the water absorbing drying box 30 and the bearing plate 31 are connected by a spring, the water absorbing drying box 30 is provided with a bump 32, and the bearing plate 31 is provided with a bump 32. The matching pressure switch 33 is used to control the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com