Electrolytic aluminum waste magnetic separation equipment

A magnetic separation equipment and electrolytic aluminum technology, which are applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high labor intensity and low picking efficiency for staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

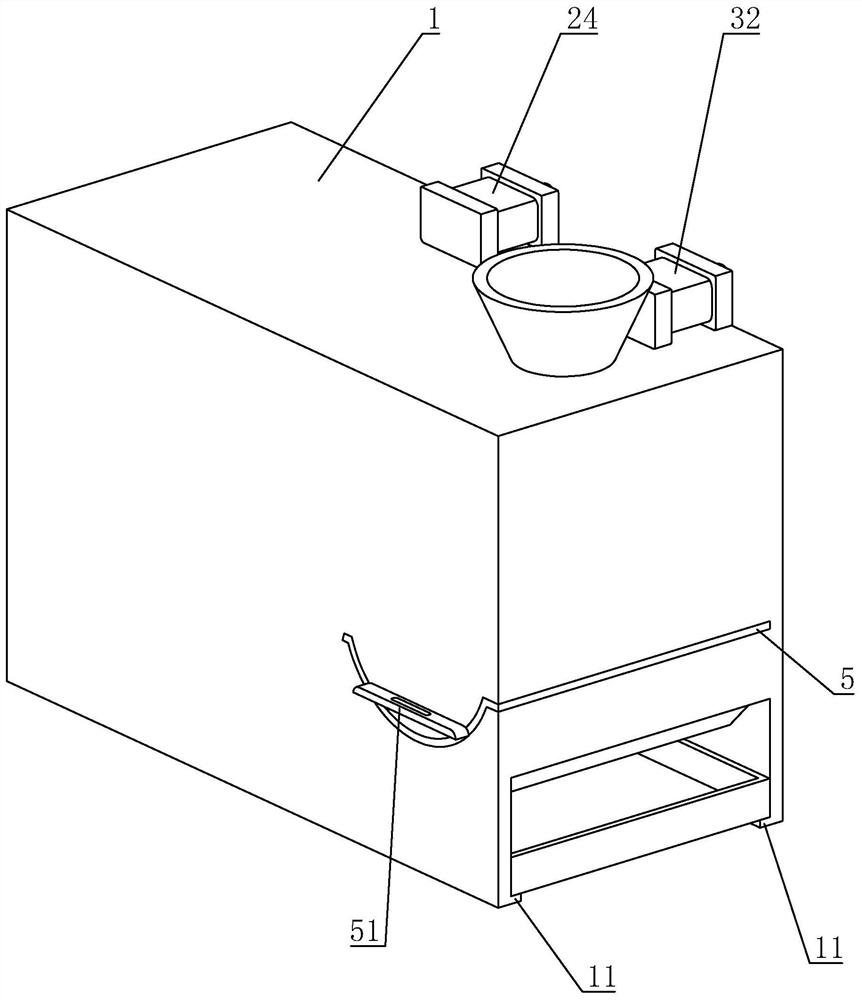

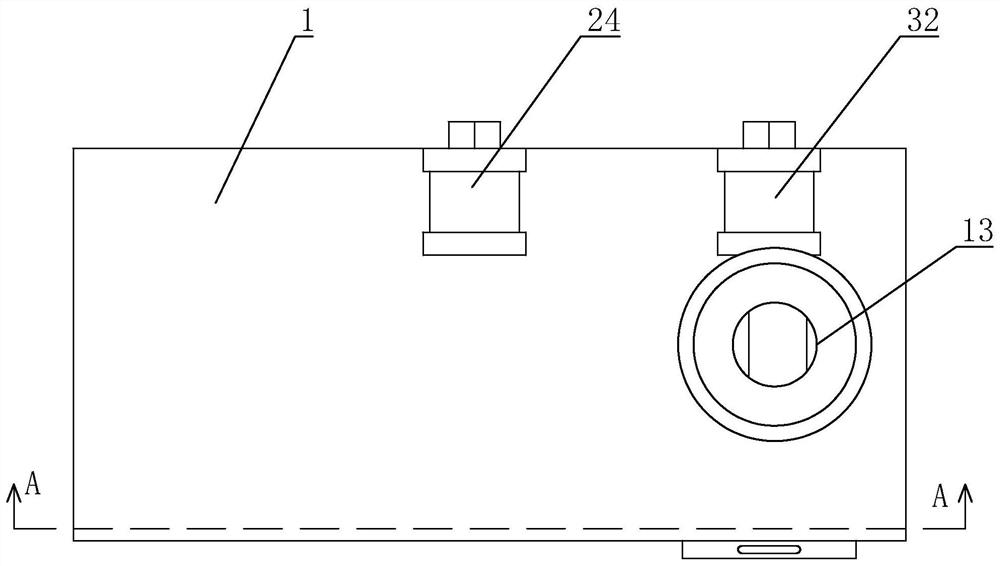

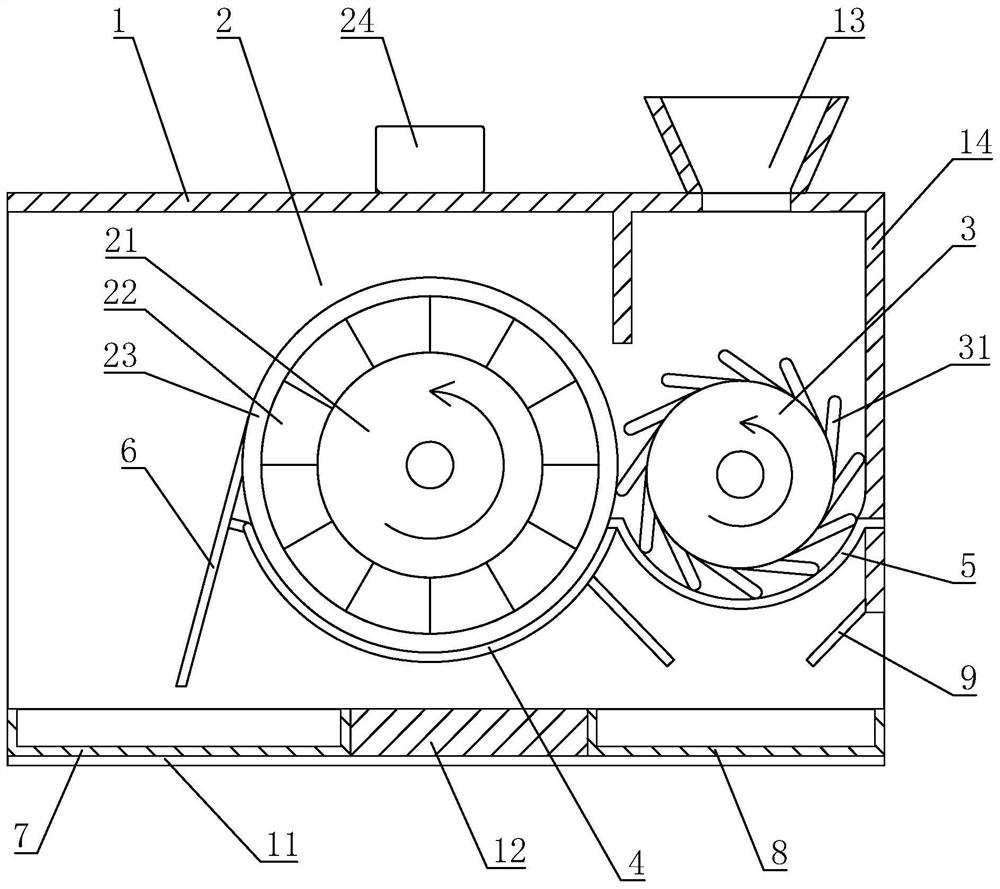

[0022] Such as Figure 1-4 As shown, it is a magnetic separation device for electrolytic aluminum scrap disclosed in the present invention, which includes an inverted U-shaped magnetic separation cylinder 1, and a magnetic separation roller 2 and a turning roller 3 are rotatably connected between the two vertical side walls of the magnetic separation cylinder 1. Magnetic separation roller 2 and overturning roller 3 are arranged side by side and both are anticlockwise rotations (direction of rotation such as image 3 The direction indicated by the middle arrow), the magnetic separation cylinder 1 is fixedly connected with an arc-shaped first support plate 4 between the two vertical side walls, the first support plate 4 is coaxially arranged with the magnetic separation roller 2, and the two vertical sides of the magnetic separation cylinder 1 The side walls are fixedly connected with a baffle plate 14, the baffle plate 14 is located at one end of the magnetic separation cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com