Wheel type paper cutting machine with follow-up tiny paper scrap adsorbing device

A paper cutter and paper scrap technology, applied in the field of wheel paper cutters, can solve problems such as occupational diseases, pollution of the ambient air in the production workshop, and the impact on the health of operating workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

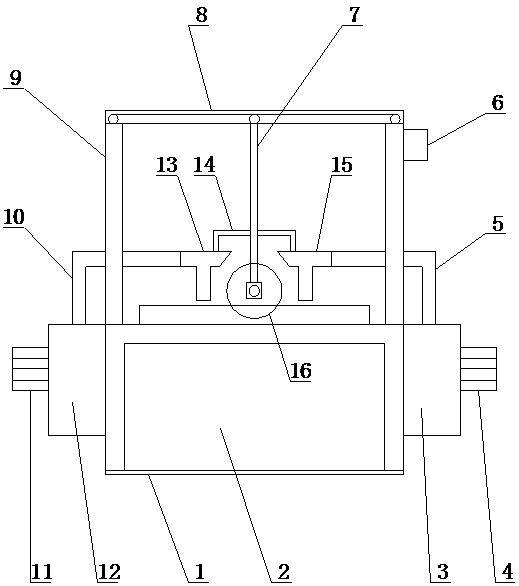

[0018] Such as figure 1 As shown, the wheeled paper cutter with a follow-up adsorption device for fine paper scraps described in this specific embodiment includes a bracket 9 installed on the work surface 1, and a slide rail 8 is arranged on the upper part of the bracket 9, and the slide rail A pulley is arranged in 8, and the pulley sleeve is arranged on the belt, and the belt is driven by the motor 6 arranged on the upper right side of the bracket 9; the pulley is connected with a connecting rod 7, and the upper end of the connecting rod 7 is a U-shaped end The connecting rod 7 is connected to the protruding shafts on both sides of the pulley through a U-shaped end. The bottom of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com