Low-temperature industrial toxic waste gas denitration equipment

A denitrification and industrial technology, applied in the field of denitrification equipment for low-temperature industrial toxic waste gas, can solve the problem of external discharge, and achieve the effect of avoiding being difficult to be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

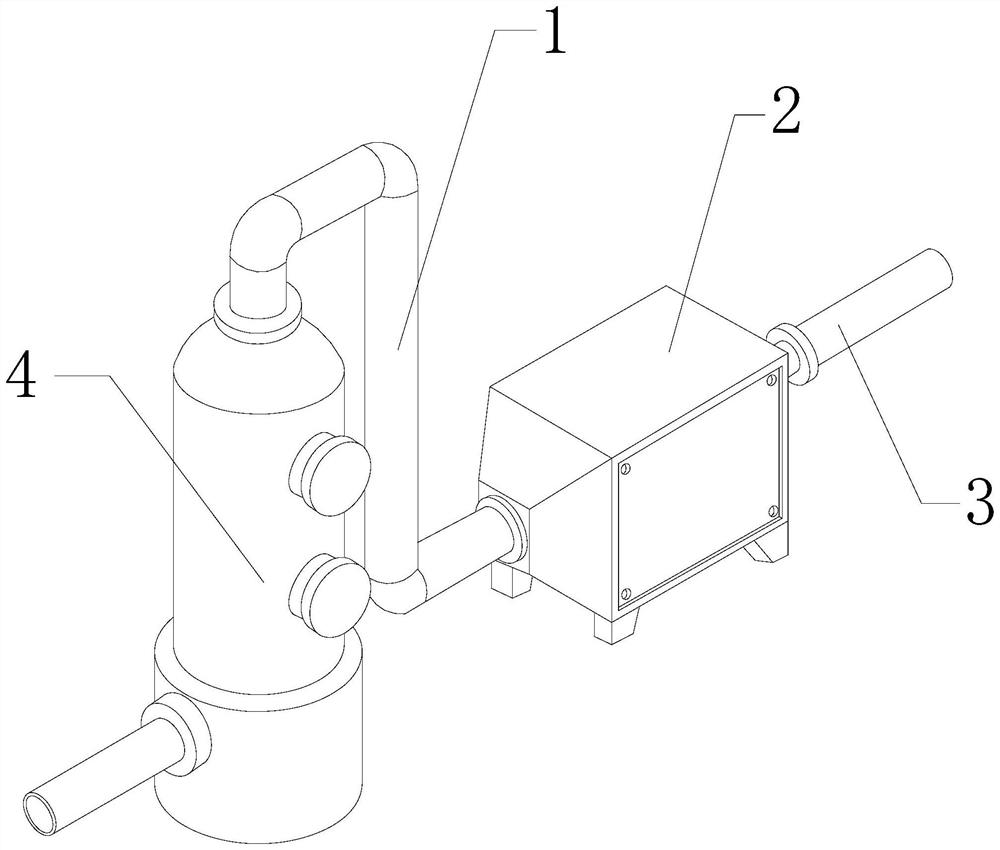

[0028] For example figure 1 -example Figure 5 Shown:

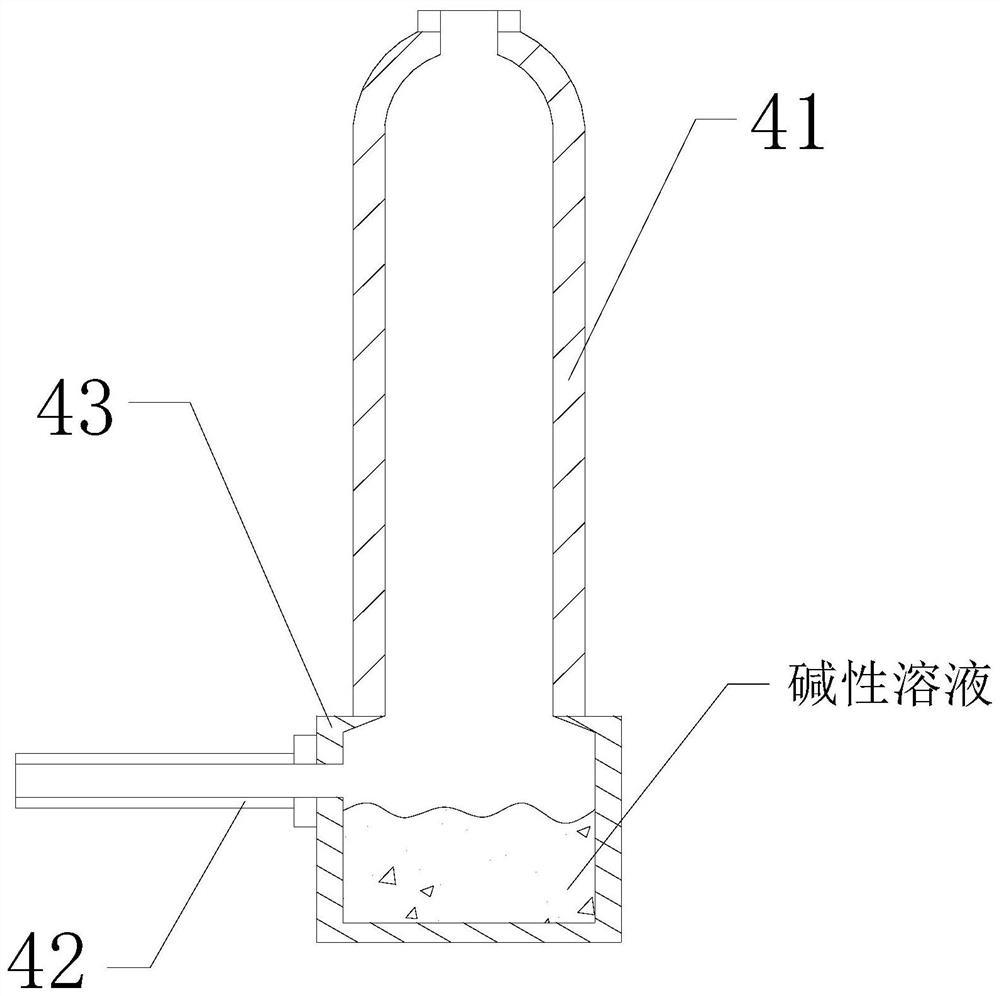

[0029] The present invention provides a denitrification device for low-temperature industrial toxic waste gas. The air pipe 3 is connected to the rear end flange of the oxidation chamber 2, and the top of the denitration chamber 4 is connected to the air guide pipe 1; the denitration chamber 4 includes a cylinder body 41, an absorption chamber 42, and an air outlet pipe 43. Fitted with the left side of the air outlet pipe 43 , the upper surface of the air outlet pipe 43 is welded to the bottom of the cylinder 41 .

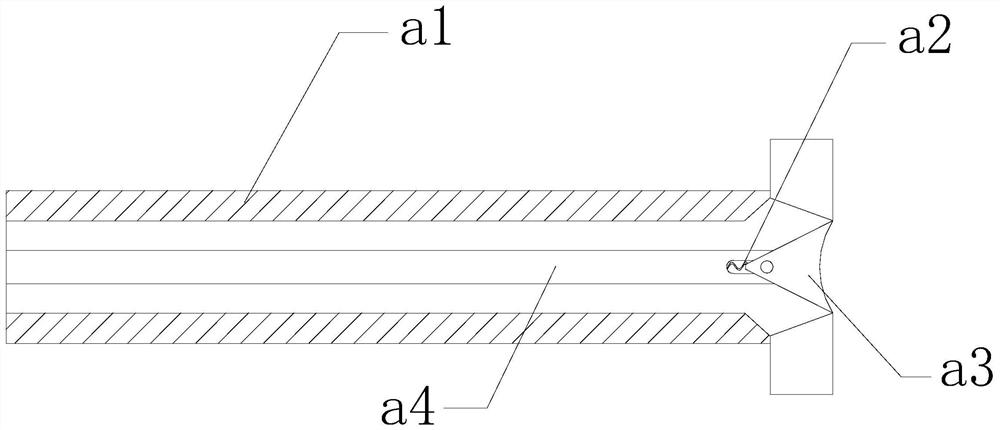

[0030] Wherein, the absorption bin 42 includes an outer tube a1, a reset bar a2, a sliding block a3, and a middle solid rod a4, and the reset bar a2 is installed between the inner wall of the sliding block a3 and the middle solid bar a4, and the sliding block a3 Engaging with the inside of the solid rod a4, the solid rod a4 penetrates the inner position of the outer tube a1, through the extrusion of the sli...

Embodiment 2

[0036] For example Image 6 -example Figure 9 Shown:

[0037] Wherein, the air outlet pipe 43 includes a blade c1, a frame c2, a bottom block c3, and a rotating shaft c4. The blade c1 is fixed on the side of the rotating shaft c4 near the upper end. The bottom fits together, the rotating shaft c4 is engaged with the inside of the bottom block c3, and the upper surface of the blade c1 has an inclined surface structure, and the blade c1 can drive the rotating shaft c4 along the The bottom block c3 rotates.

[0038]Wherein, the blade c1 includes a combination plate c11, a weight reduction cavity c12, and a guide groove c13, the combination plate c11 is fixed on the upper surface of the guide groove c13, and the weight reduction cavity c12 penetrates the inner position of the combination plate c11, The weight reducing cavity c12 has a hollow structure, and the weight reducing cavity c12 can reduce the overall weight of the connecting plate c11, so that the object can be rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com