Autoclaved aerated concrete slab and preparation method thereof

A technology of concrete slab and autoclaved aeration, which is applied in clay preparation device, separation method, mixing operation control, etc., can solve the problems of poor environment quality and uneven mixing of raw materials at the production site, and achieve the effect of increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

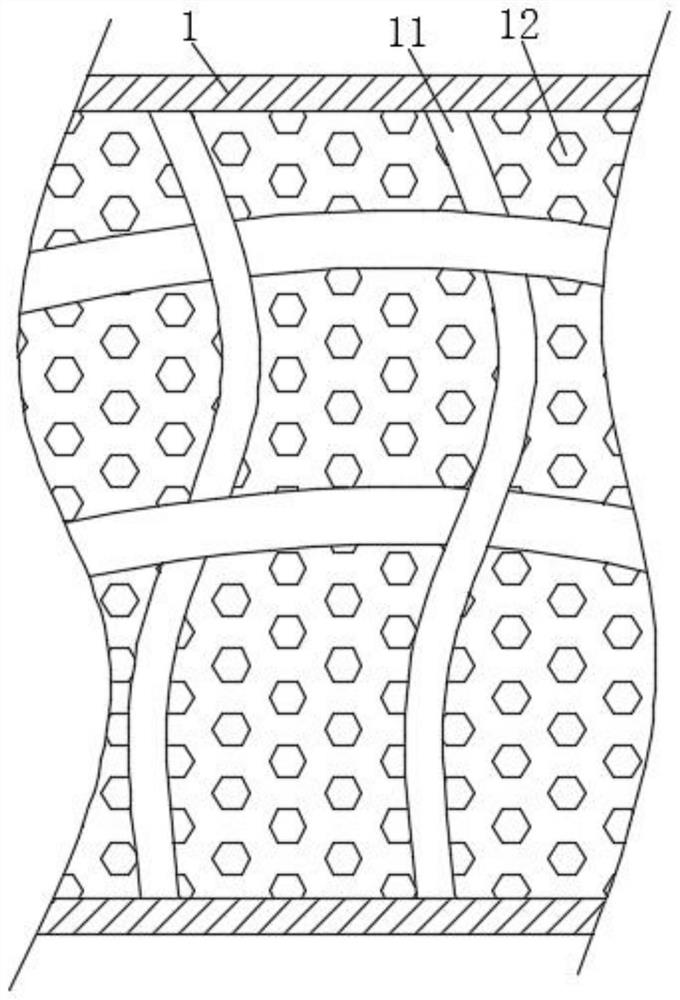

[0039] like Figure 1-6As shown, the present invention provides an autoclaved aerated concrete panel, including a steam pressurized concrete panel 1, a steel skeleton 11 is fixedly connected to the inner wall of the steam pressurized concrete panel 1, and the inner wall of the steam pressurized concrete panel 1 is connected with the steel bars. Concrete 12 is filled between the outer surfaces of the skeleton 11 .

[0040] In the present embodiment, the steel skeleton 11 is firstly fixed on the inner wall of the steam pressurized concrete slab 1 according to the requirements, and then the concrete 12 is filled between the nickel coins of the steam pressurized concrete slab 1 and the outer surface of the steel skeleton 11, After standing until the concrete 12 is completely solidified and fixed, the concrete slab can be steam cured at high temperature and high pressure through the steam curing kettle, so that it has excellent fire resistance, fire resistance, sound insulation, he...

Embodiment 2

[0042] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention also provides a method for preparing an autoclaved aerated concrete slab, and the preparation method for an autoclaved aerated concrete slab consists of the following steps:

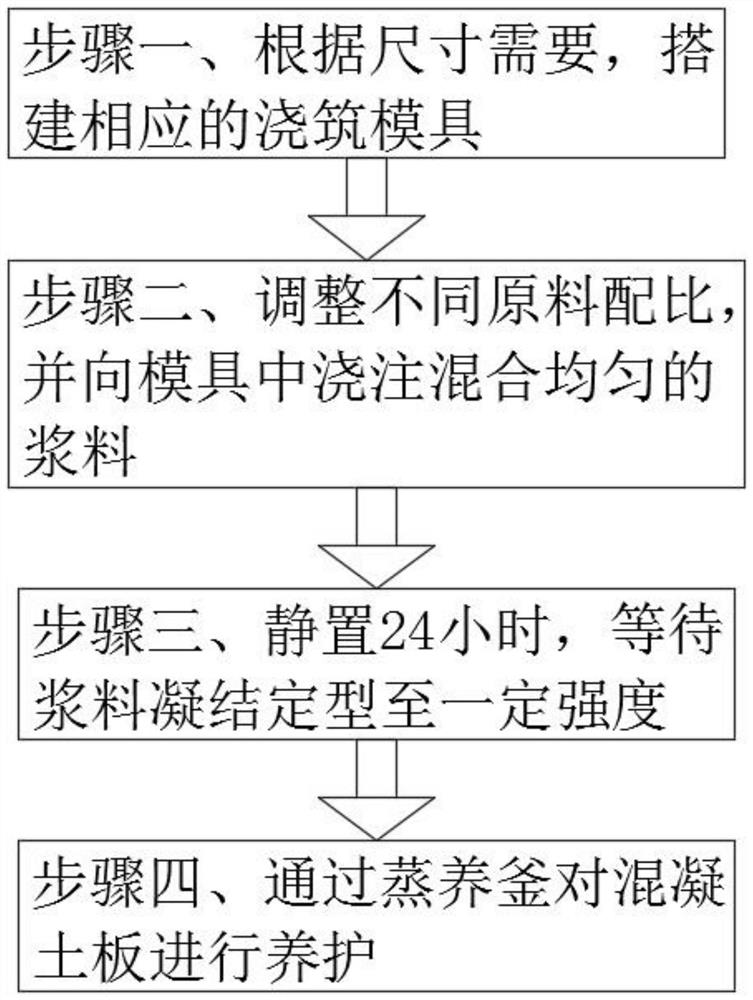

[0043] Step 1. According to the size needs, build the corresponding pouring mold;

[0044] Step 2, adjusting the ratio of different raw materials, and pouring the mixed slurry into the mold, so that the slurry fills the gap between the steam pressurized concrete slab 1 and the steel skeleton 11;

[0045] Step 3, stand for 24 hours, wait for the slurry to coagulate and shape to a certain strength, so as to facilitate subsequent processing;

[0046] Step 4, curing the concrete slab through the steam curing kettle, and through the curing process of high temperature and high pressure, the autoclaved aerated concrete slab has various excellent properties.

Embodiment 3

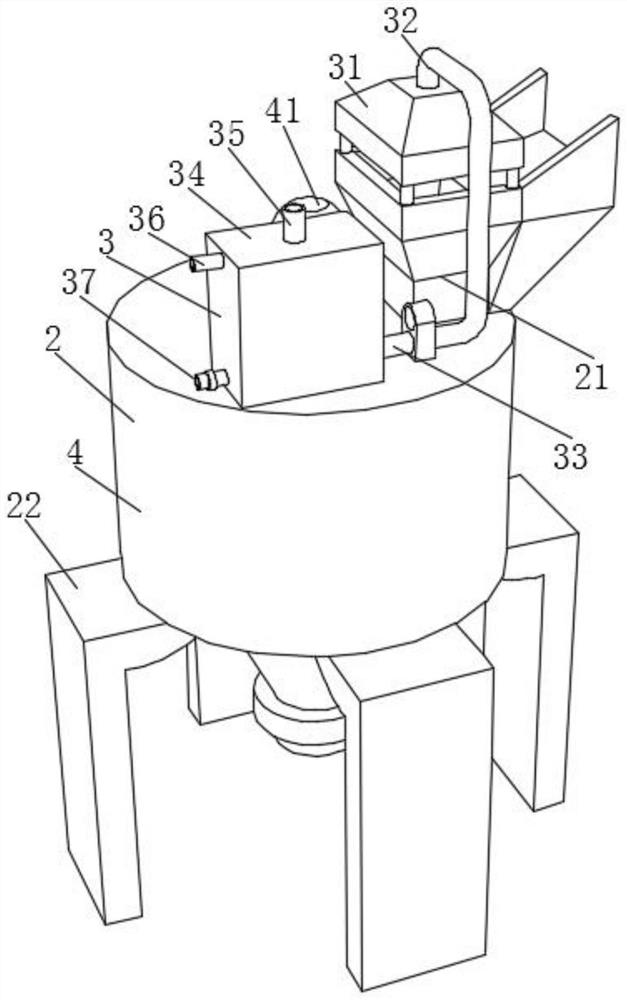

[0048] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention also provides an autoclaved aerated concrete slurry mixing device, comprising a concrete slurry mixing device 2, and the upper surface of the concrete slurry mixing device 2 is fixed A feeding hopper 21 is connected, a bracket 22 is fixedly connected to the lower surface of the concrete slurry mixing device 2, a dust processing mechanism 3 is arranged on the upper surface of the concrete slurry mixing device 2, and a stirring mechanism is arranged inside the concrete slurry mixing device 2 4. The dust processing mechanism 3 includes a dust suction hood 31, the lower surface of which is fixedly connected with the upper surface of the feeding hopper 21, and an adsorption processing box 34 is arranged on one side of the dust suction hood 31, and the stirring mechanism 4 includes a The motor 41, the outer surface of the motor 41 is fixedly connected with the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com