Multifunctional sawing machine for machining fast-assembly box steel

A sawing machine and multi-functional technology, applied in the direction of metal sawing equipment, metal processing equipment, sawing machine equipment, etc., can solve the problems of severe device vibration, cutting size deviation, and more metal debris, so as to avoid deviation, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

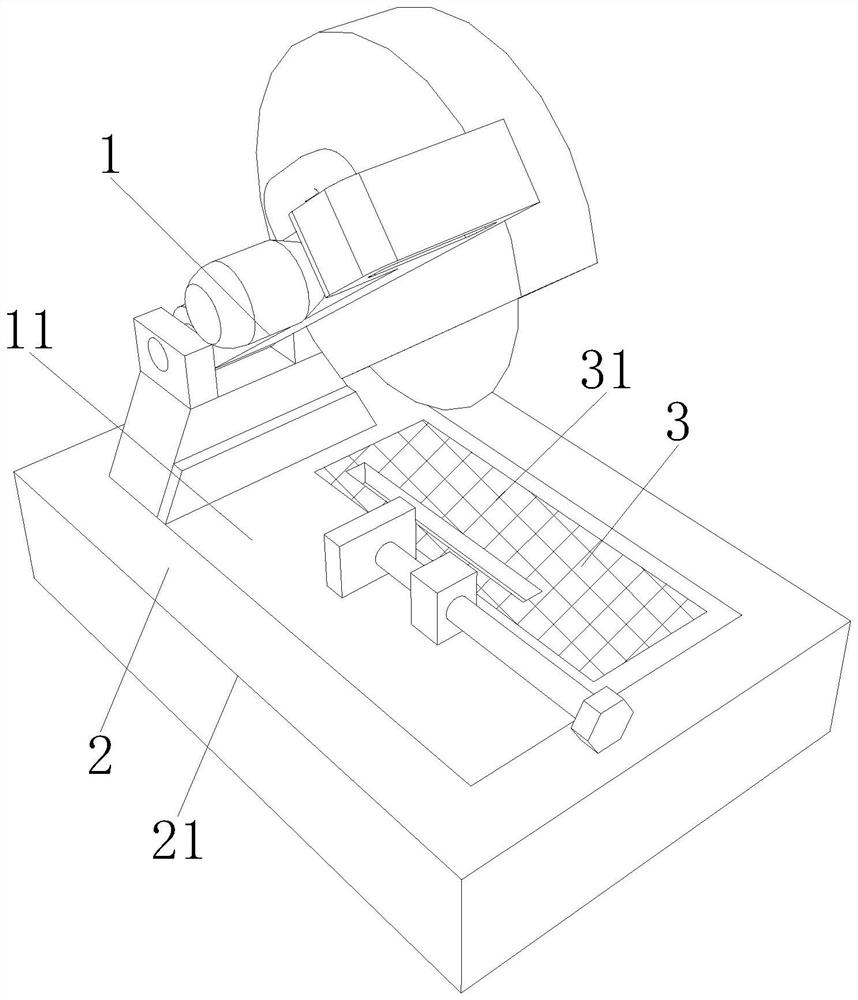

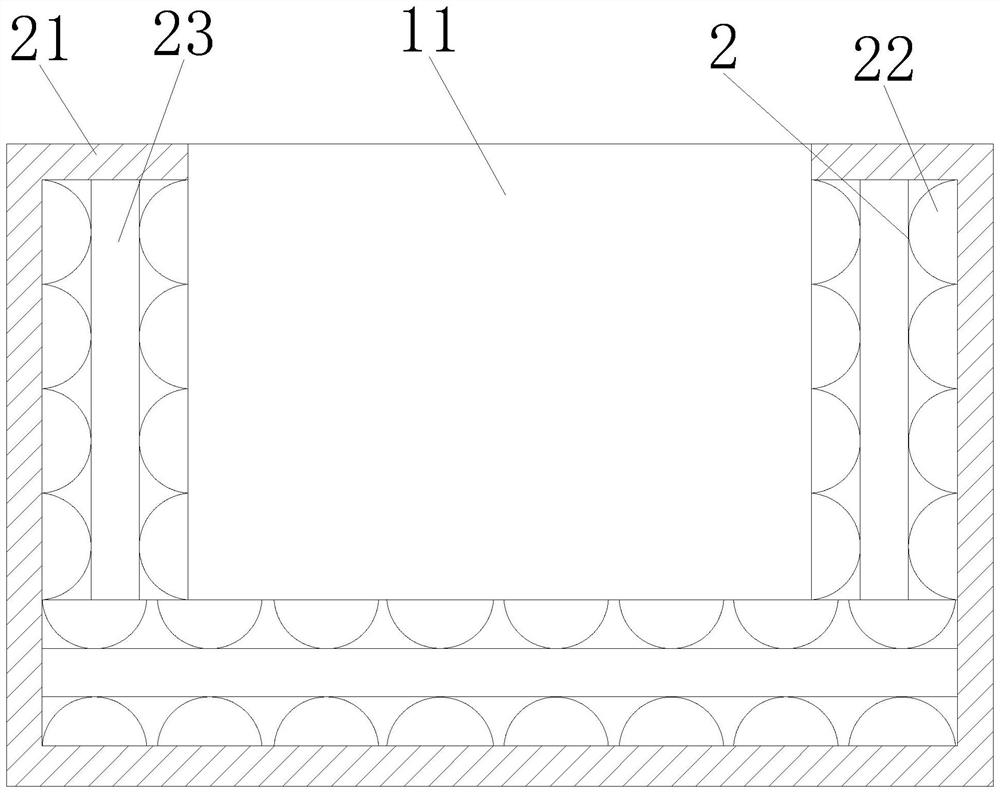

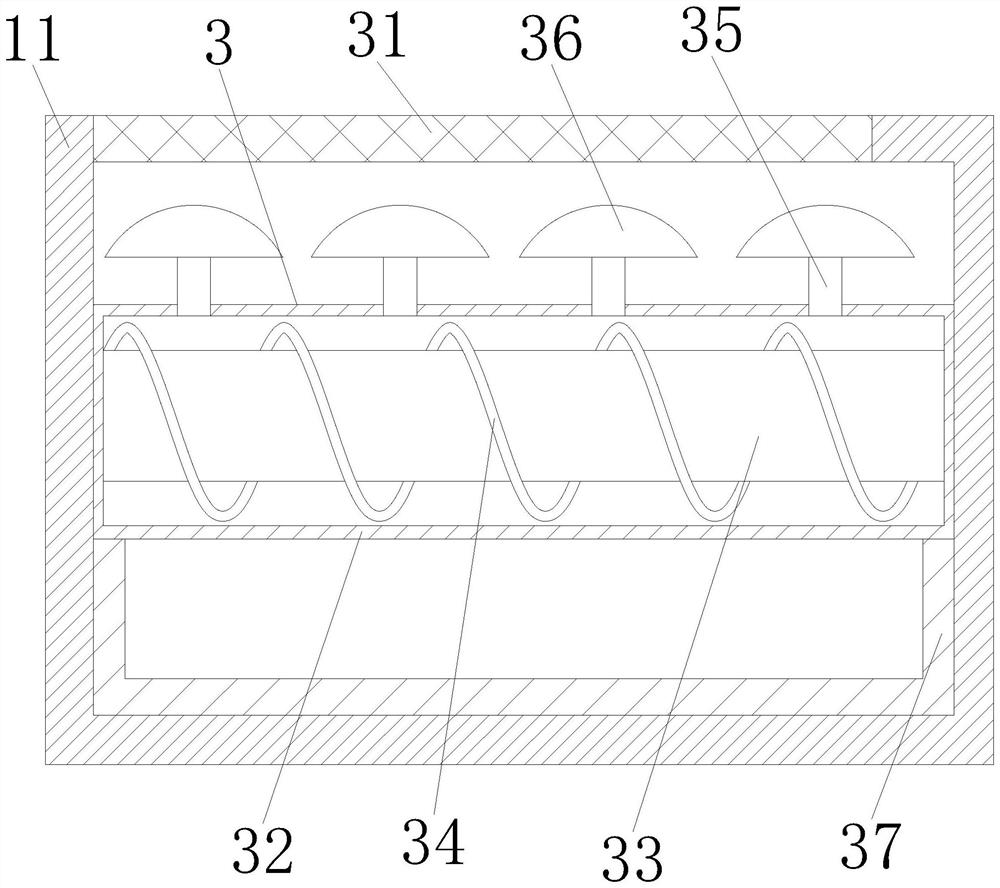

[0035] Such as Figure 1-6 As shown, the present invention provides a multi-functional sawing machine for fast LCL steel processing, including a sawing machine main body 1, the lower surface of the sawing machine main body 1 is fixedly connected with a base 11, and the outer side of the base 11 is provided with a shock absorber Mechanism 2, the inside of the base 11 is provided with a debris processing mechanism 3, the shock absorbing mechanism 2 includes a shock absorbing shell 21, the inner wall of the shock absorbing shell 21 is fixedly connected with the outer surface of the base 11, and the inside of the shock absorbing shell 21 is provided with a soft Quality cushioning hemisphere 22, debris treatment mechanism 3 includes leakage debris net 31, the outer surface of leakage debris net 31 is fixedly connected with the inner wall of base 11, and the inside of base 11 is provided with soft iron core 33, coil 34, magnetism guide plate 35 And adsorption shell 36, the inwall of...

Embodiment 2

[0038] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, an elastic plate 226 is fixedly connected to the inner wall of the soft cushioning hemisphere 22, and the elastic plate 226 is arranged on one side of the slide rail 222, elastically The inner wall of the plate 226 is fixedly connected with a magnet 227, the outer surface of the slide rail 222 is movably connected with an elastic buffer ball 225, and the inner wall of the elastic buffer ball 225 is fixedly connected with a soft support plate 2251, one side of the soft support plate 2251 An elastic corrugated plate 2252 and an elastic airbag 2253 are fixedly connected, and an abutment rod 2254 is fixedly connected on the outer surface of the elastic airbag 2253 .

[0039] In this embodiment, when the soft cushioning hemisphere 22 is elastically deformed, the elastic plate 226 is driven to deform, so that the distance between the magnets 227 is reduce...

Embodiment 3

[0041] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner wall of the base 11 is fixedly connected with a composite magnetically conductive shell 32, and the two ends of the soft iron core 33 are respectively connected to the composite magnetically conductive shell 32 The inner wall of the coil is fixedly connected, the coil 34 is sleeved on the outer surface of the soft iron core 33, the two ends of the coil 34 are electrically connected to the external power supply, and one end of the magnet guide plate 35 is fixedly connected to the upper surface of the composite magnet guide shell 32, and the adsorption The lower surface of the casing 36 is fixedly connected with the other end of the magnetic-conducting plate 35 , and the lower surface of the composite magnetic-conducting casing 32 is provided with a waste hopper 37 , and the outer surface of the waste hopper 37 is movably connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com