Dust absorbing and treating device for building site

A technology for construction sites and treatment devices, which is applied in the directions of combination devices, smoke and dust removal, cleaning methods and utensils, etc., can solve the problems of decreased filtration efficiency, high use cost, and muddy ground, and achieves reduction of air dust content and simple structure. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

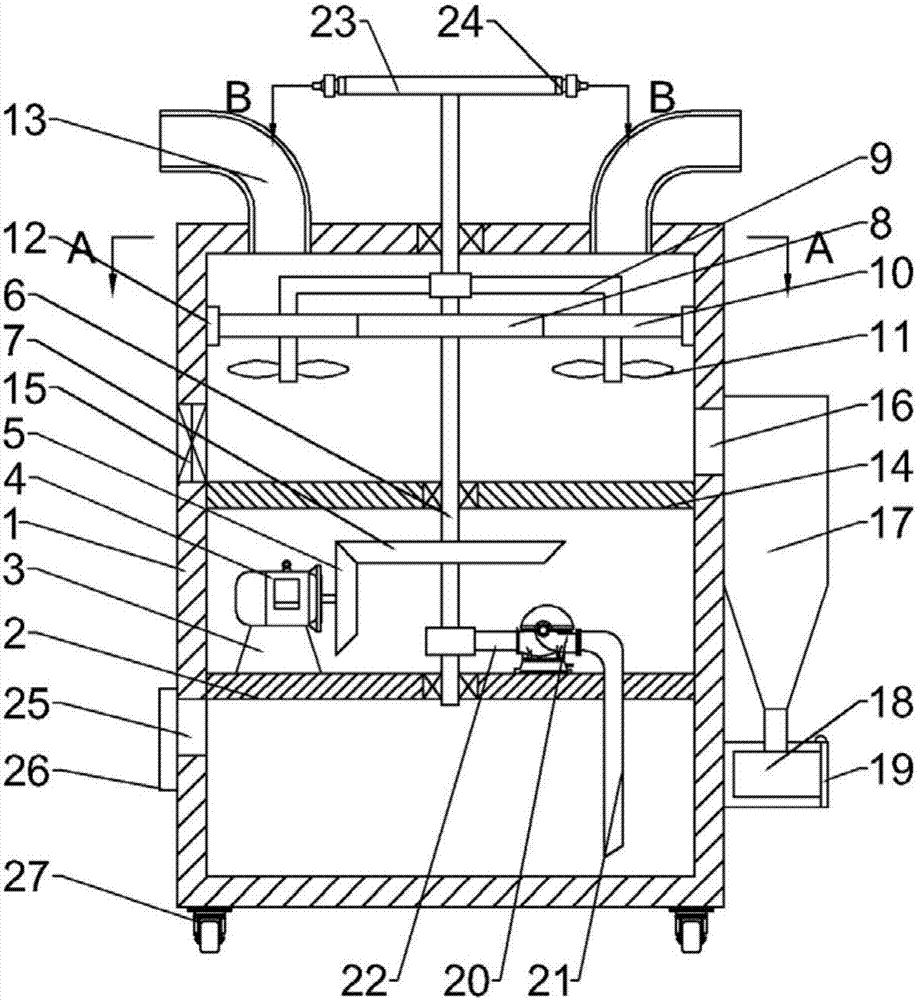

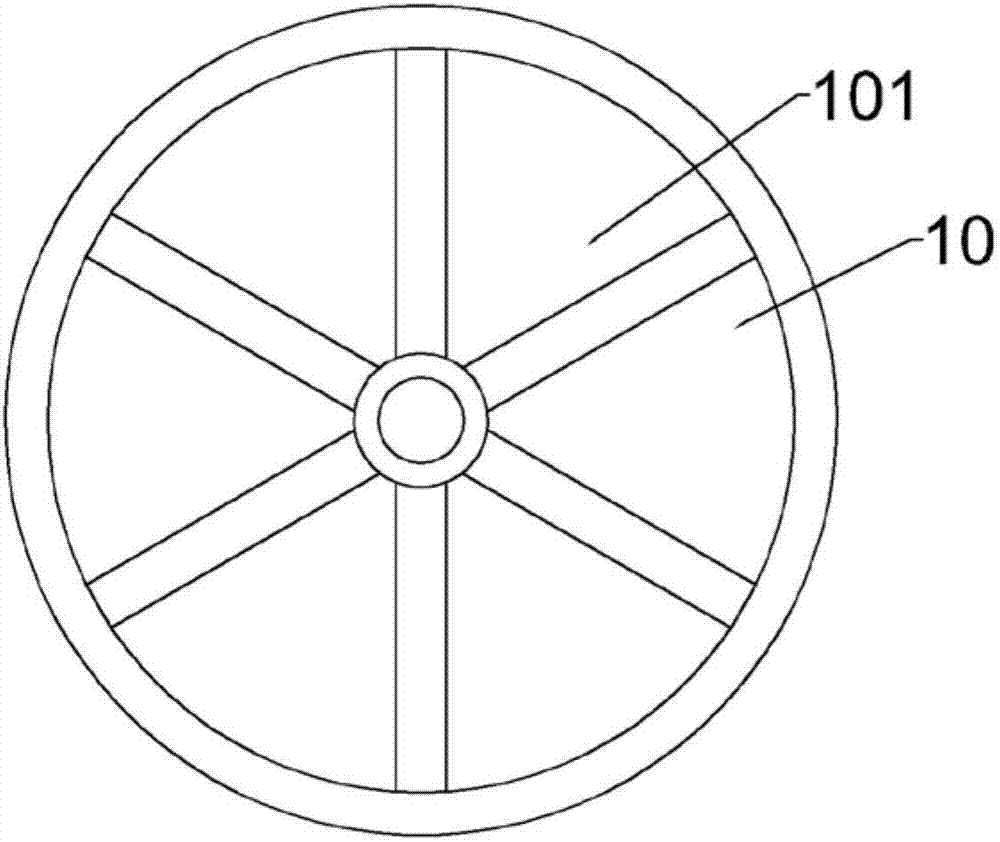

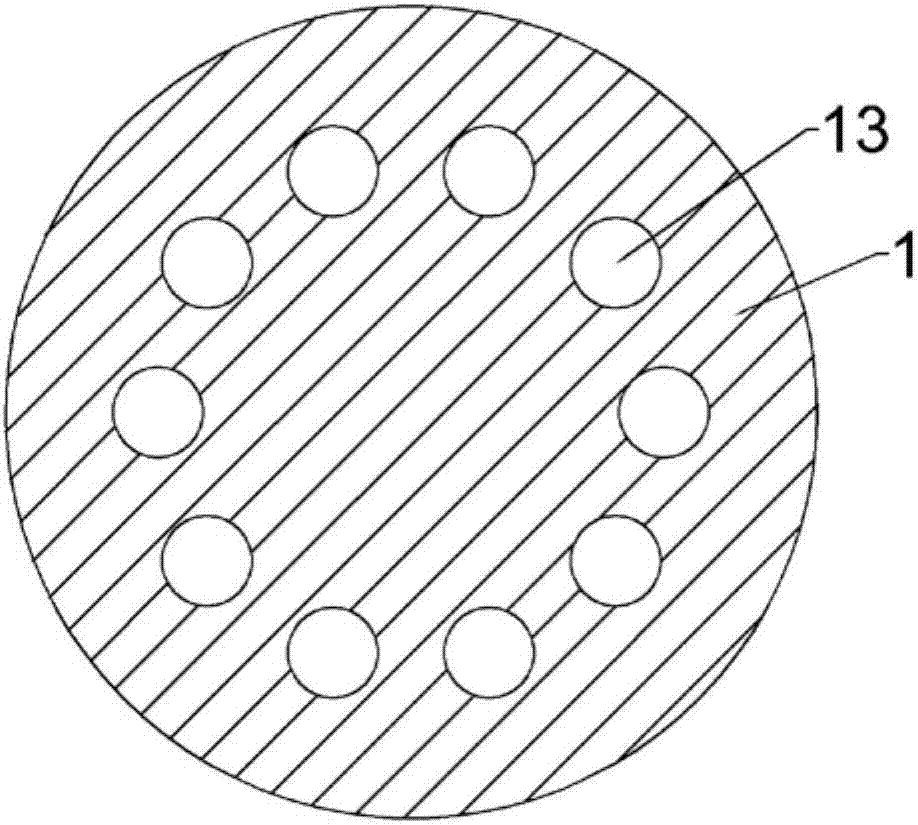

[0022] see Figure 1-4 , a dust absorbing and processing device for a construction site, comprising a housing 1, a lower partition 2 is fixedly connected to the lower part of the housing 1, and a motor base 3 is fixedly connected to the left side above the lower partition 2, and the motor base 3 A motor 4 is fixedly connected to the top, and the output end of the motor 4 is fixedly connected to a driving bevel gear 5. The middle part above the lower partition 2 is connected to a longitudinal rotation shaft 6 through bearing rotation. The longitudinal rotation shaft 6 is a tubular structure, and the longitudinal rotation shaft 6 is fixedly connected with a driven bevel gear 7 below, and the driven bevel gear 7 is meshed with the driving bevel gear 5. The outer side of the longitudinal rotation shaft 6 is fixedly connected with a driving gear 8, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com