A modified epoxy nanocomposite material based on layered nickel silicate-coated polyaniline composite nanofibers and its preparation method

A technology of composite nanofibers and layered silicic acid, which is applied in the field of epoxy nanocomposites and its preparation, can solve the problems of decreased mechanical properties of epoxy resin materials, difficulty in preparing EP nanocomposites, difficulty in dispersing nanomaterials, etc., and achieves Effect of improving mechanical properties, large specific surface area, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1, preparation of phytic acid (PA) doped polyaniline (PANI)

[0026] Dissolve 0.91mL of PA and 0.90mL of aniline in 5mL of deionized water successively to configure solution A; dissolve 0.57g of APS in 2mL of deionized water to configure solution B; keep stirring and keep at 0~5℃ At low temperature, slowly add solution B into solution A, and react for 30 minutes until the color of the solution changes from brown to dark green; the above solution is left at 0-5°C for 24 hours, and after several times of centrifugation, washing and drying, Vacuum drying at 60°C for 24 hours to obtain PA-doped PANI nanofibers (PA-PANI);

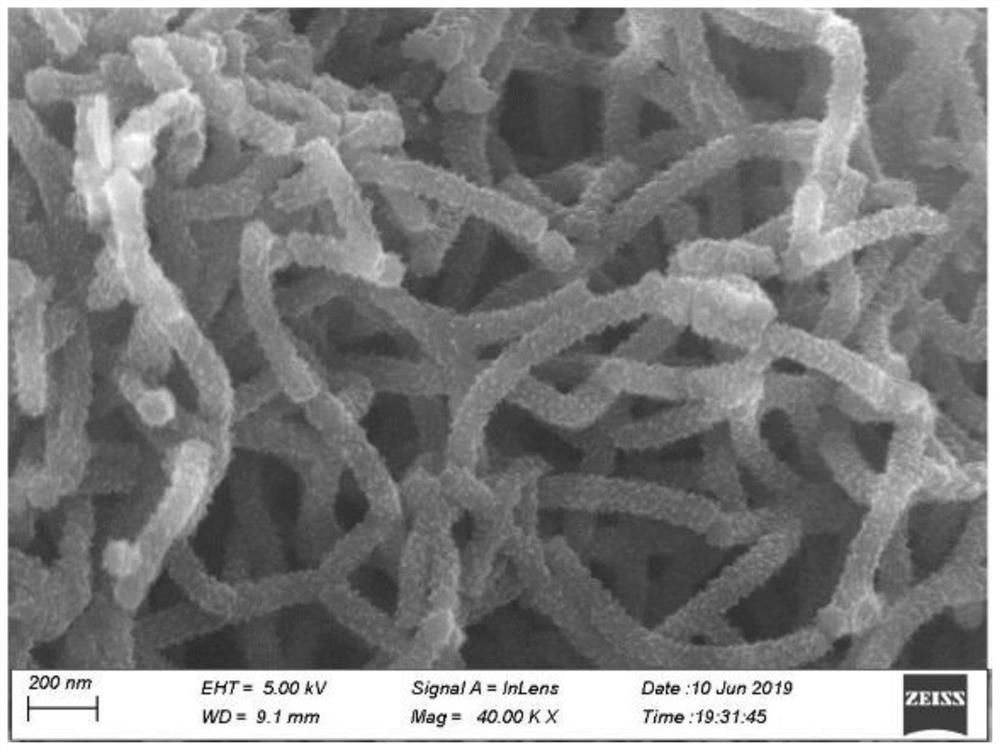

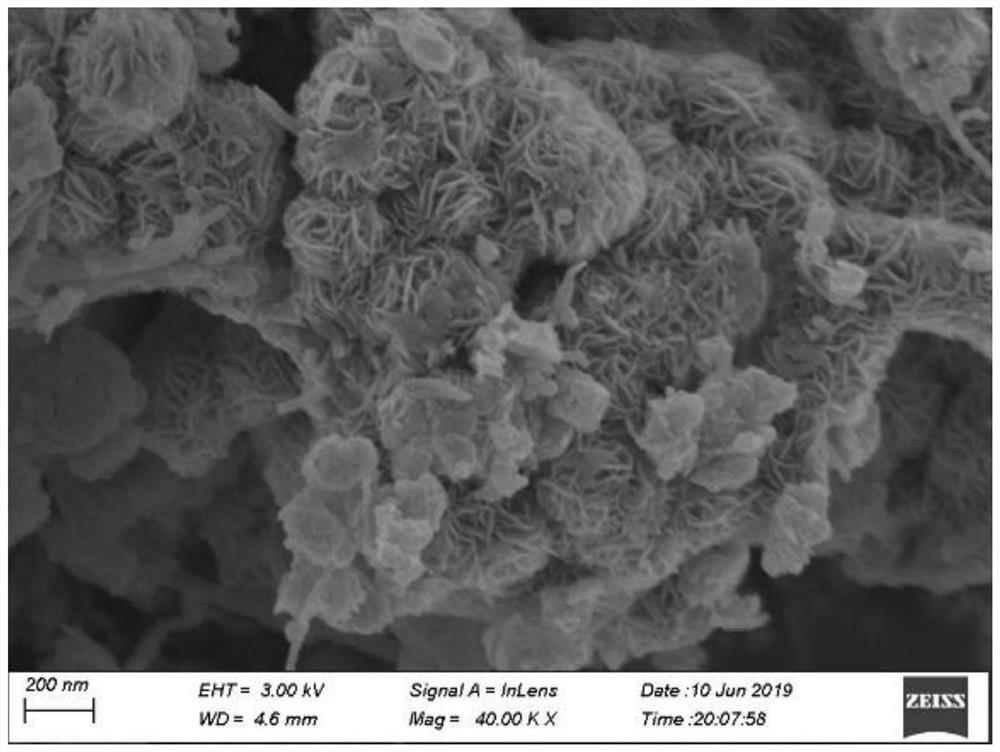

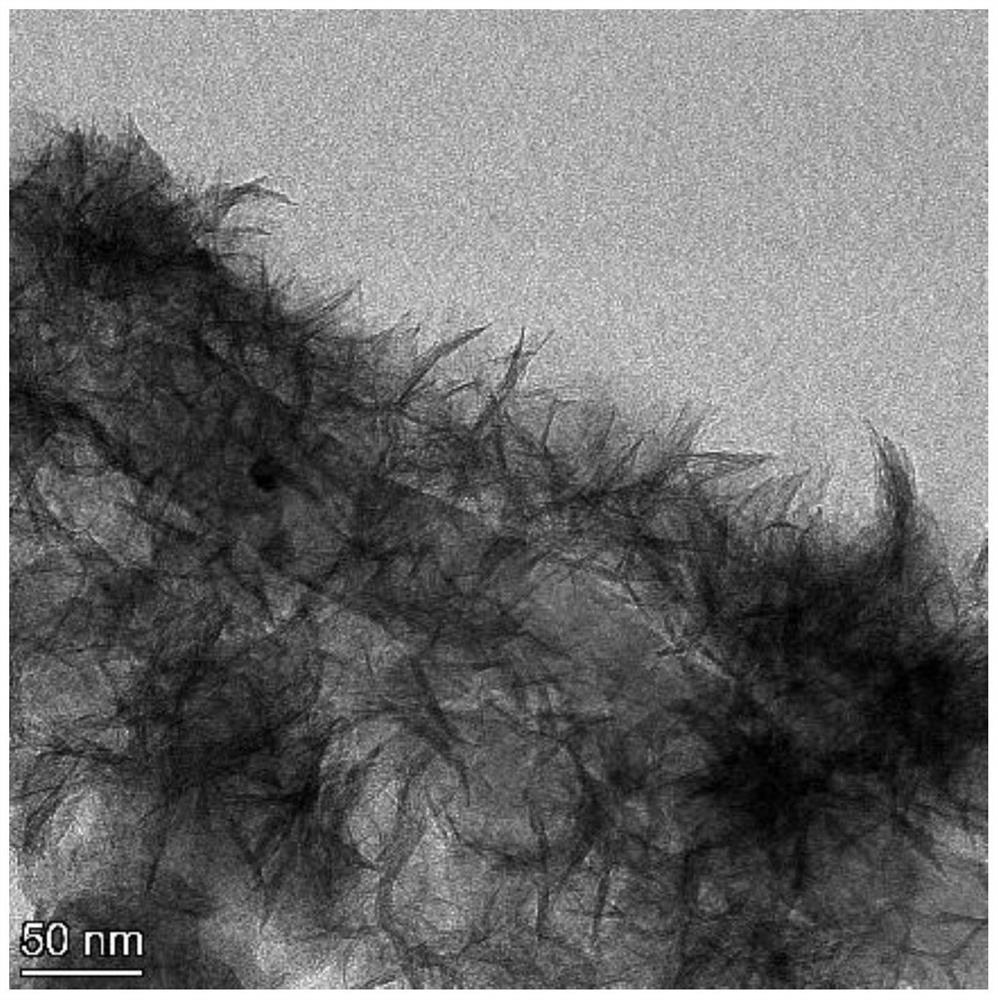

[0027] S2. Synthesis of NiPS@PA-PANI

[0028] At room temperature, weigh 1.0g of CTAB and dissolve it in 30ml of deionized water. After ultrasonic treatment for 10min, add 0.2g of PA-PANI. After 30min of ultrasonic treatment to disperse, add 80ml of absolute ethanol and continue ultrasonic treatment for 30min; Measure 2ml of NH 3 ·H 2 O was added to ...

Embodiment 2

[0032] Example 2: S1-S2 is the same as Example 1, the difference is that the amount of NiPS@PA-PANI powder in S3 is 0.6g, the amount of epoxy resin is 15.42g, and the amount of DDM is 3.98g.

Embodiment 3

[0033] Example 3: S1-S2 is the same as Example 1, the difference is that the amount of NiPS@PA-PANI powder in S3 is 1.00g, the amount of epoxy resin is 15.10g, and the amount of DDM is 3.90g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com