Polyethylenimine modified graphene oxide and epoxy nano composite material thereof

A technology of polyethyleneimine and composite materials, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. It can solve the problem of insufficient bonding strength of compatible interfaces and the inability to fully utilize the advantages of graphene. , The mechanical properties of composite materials need to be further improved, etc., to achieve the effects of improving mechanical properties, elongation at break, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

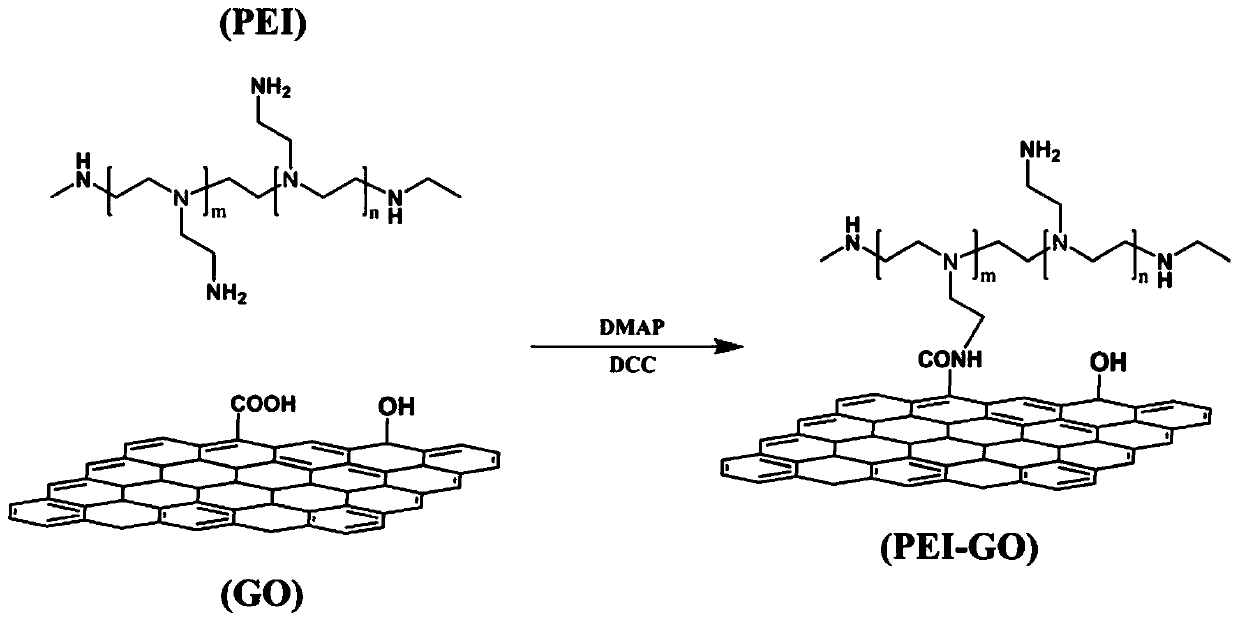

[0036] Embodiment 1, the preparation of polyethyleneimine modified graphene oxide of the present invention

[0037] according to figure 1 The synthetic route shown is to synthesize the polyethyleneimine-modified graphene oxide (PEI-GO) of the present invention.

[0038] Weigh 0.4g graphene oxide (GO), C / O molar ratio is (6.9~7.1): 3, purchased from Beijing Carbon Century Technology Co., Ltd.) cell crushing ultrasonic dispersion in 400mL dry dimethylacetamide (DMAC) , 4 mmol of dimethylaminopyridine (DMAP) and N, N-dicyclohexylcarbodiimide (DCC) were added in proportion to the dispersed GO suspension, and the water bath was ultrasonically activated for 2 h. The GO suspension after dispersion activation was added into a 1000mL three-necked flask, and 12mmol of polyethyleneimine (PEI, purchased from Shanghai Demao Co., Ltd.) was added. The mixture was reacted at 90° C. for 24 hours. After the reaction was completed, it was cooled to room temperature, and filtered under reduced ...

Embodiment 2

[0039] Embodiment 2, preparation of polyethyleneimine modified graphene oxide / epoxy nanocomposite (PEI-GO / EP) of the present invention According to the formula shown in Table 1, weigh modified graphene oxide PEI-GO, with 1 : Ultrasonic dispersion of 1mg / mL in acetone solution, and 70g of TDE-85 epoxy resin (purchased from Hubei Xinrunde Chemical Co., Ltd.) was added to the uniformly dispersed solution after ultrasonication, and mechanically stirred at 65°C for 14h to remove solvent. Put the obtained modified graphene oxide / TDE-85 epoxy resin mixture into a vacuum oven and dry it under vacuum at 65°C until no bubbles are generated in the mixture to remove residual solvent. Weigh 4' diaminodiphenylmethane (DDM) and 3,5-diethyl-2,4 toluenediamine (DETDA) mixed curing agent, add modified graphene oxide / TDE-85 epoxy resin after melting In the solution, electric constant speed stirring makes the curing agent and resin fully mixed. The resulting mixture was placed in a vacuum oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com