Modified zirconium phosphate-epoxy nanometer composite material and preparation method thereof

A nano-composite material, zirconium phosphate technology, applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of strong alkalinity, low efficiency of organically modified zirconium phosphate, and toxic intercalation agent, etc., to achieve Improved anti-corrosion performance, efficient peeling, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

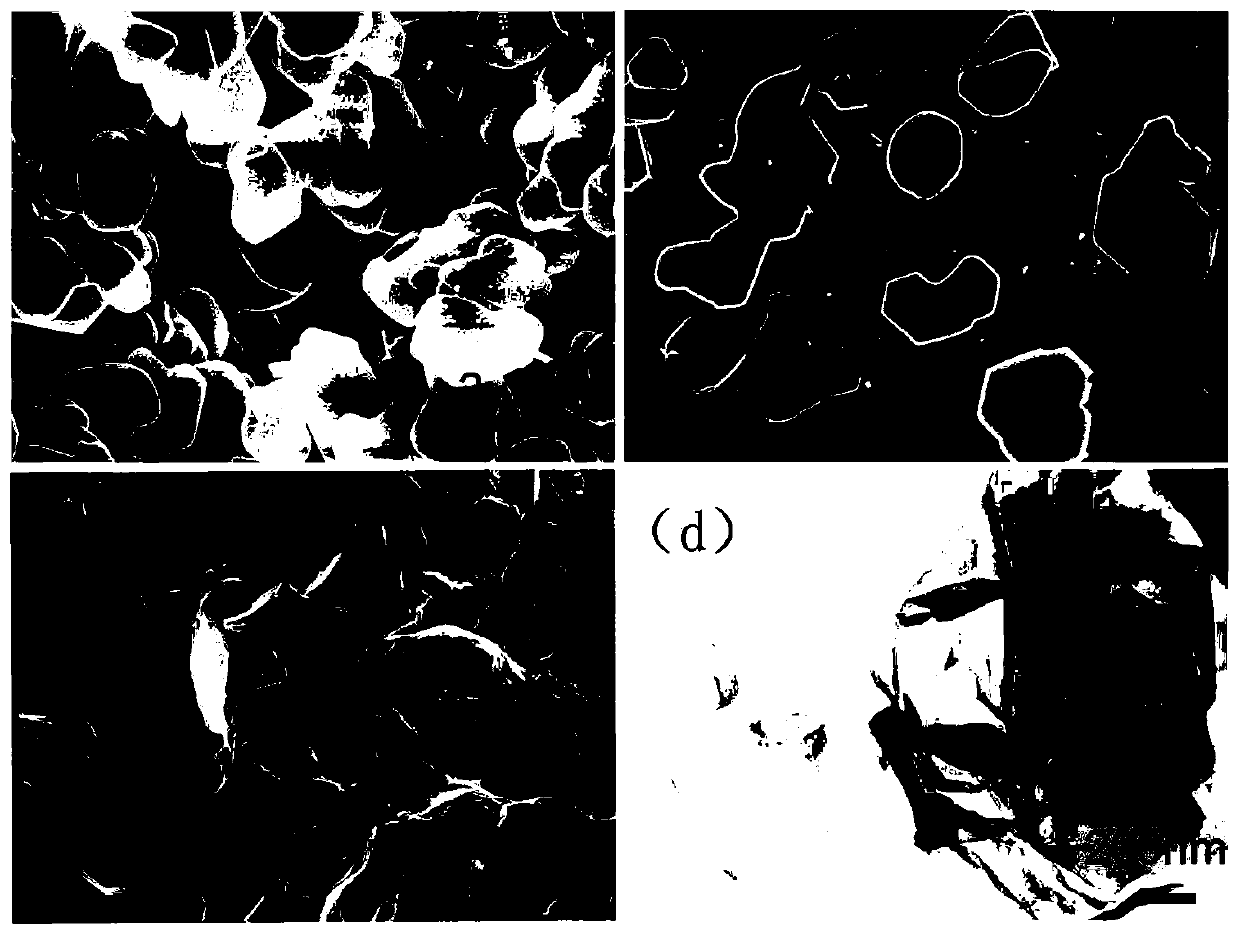

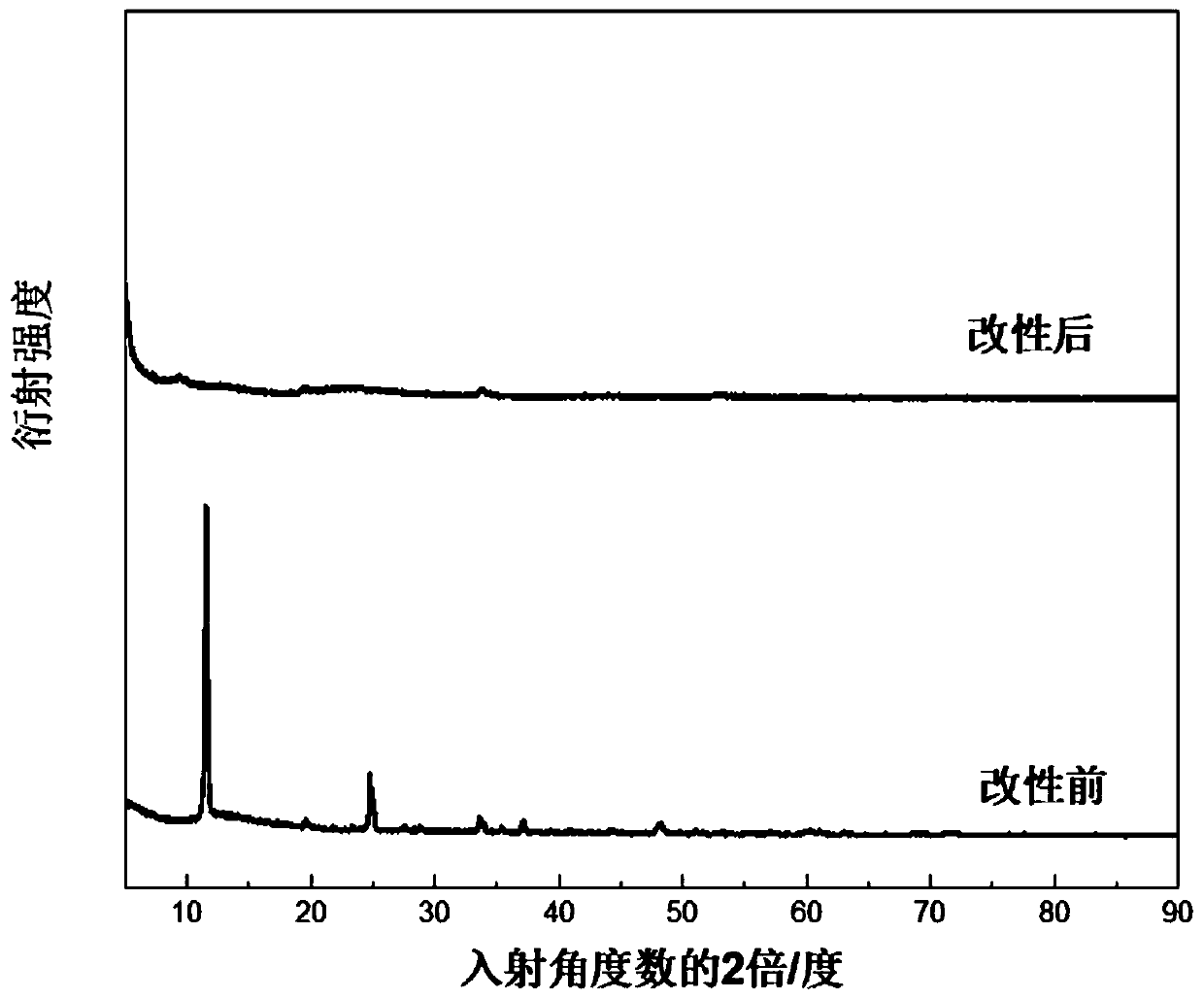

[0053] A preparation method of modified zirconium phosphate-epoxy nano composite material, comprising the following steps:

[0054] (1) Intercalation and stripping of nano-zirconium phosphate: in parts by mass, 1 part of triethanolamine, 1 part of disodium edetate, and 100 parts of water are mixed, and 5 parts of layered α-phosphoric acid are added to the above solution Zirconium (diameter of 1.28 microns, thickness of 4 nanometers, ion exchange capacity of 500mol / 100g), vibrating evenly by hand (100 times / min, amplitude of 40 mm, temperature of 25 degrees Celsius, working time of 20 seconds) , ultrasonic for 30 minutes (power 100W, frequency 50Hz, temperature 10 degrees Celsius), to obtain the peeled single-layer zirconium phosphate.

[0055] (2) Add 1 mol / L stripping agent hydrochloric acid solution to step (1), adjust the pH to 2; centrifuge and wash at 6000r / min for three times, and pour off the supernatant.

[0056] (3) Add the zirconium phosphate after stripping agent t...

Embodiment 2

[0067] A preparation method of modified zirconium phosphate-epoxy nano composite material, comprising the following steps:

[0068] (1) Intercalation stripping of nano-zirconium phosphate: in parts by mass, mix 1 part of N-methylethanolamine, 0 parts of disodium edetate, and 360 parts of water, and add 10 parts of layered α-zirconium phosphate (diameter of 0.8 microns, thickness of 4 nanometers, ion exchange capacity of 500mol / 100g), vibrating evenly by hand (100 times / min, amplitude of 40 mm, temperature of 25 degrees Celsius, working time of 20 seconds), ultrasonic for 30 minutes (power 100W, frequency 50Hz, temperature 10 degrees Celsius), to obtain the peeled single-layer zirconium phosphate.

[0069] (2) Add stripping agent 1mol / L hydrochloric acid solution to (1), adjust the pH to 2; 6000r / min centrifuge wash three times, pour off the supernatant.

[0070] (3) Add 100 parts of deionized water to zirconium phosphate after stripping agent treatment, add 5 parts of polyethyl...

Embodiment 3

[0079] A preparation method of modified zirconium phosphate-epoxy nano composite material, comprising the following steps:

[0080] (1) Intercalation stripping of nano-zirconium phosphate: in parts by mass, 1 part of triethanolamine, 5 parts of sodium dodecyl sulfate, and 200 parts of water are mixed, and 20 parts of layered α-phosphoric acid are added to the above solution Zirconium (diameter of 0.8 microns, thickness of 4 nanometers, ion exchange capacity of 500mol / 100g), vibrating evenly by hand (100 times / min, amplitude of 40 mm, temperature of 25 degrees Celsius, working time of 20 seconds) , ultrasonic for 30 minutes (power 100W, frequency 50Hz, temperature 10 degrees Celsius), to obtain the peeled single-layer zirconium phosphate.

[0081] (2) Add stripping agent 1.0 mol / L hydrochloric acid solution to (1), adjust the pH to 4; centrifuge and wash at 6000r / min three times, and pour off the supernatant.

[0082] (3) Add the zirconium phosphate after stripping agent treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com