Polyetheramine-modified graphene oxide and epoxy composite nano-material thereof

A composite material and polyetheramine technology, which is applied in the field of polyetheramine modified graphene oxide and its epoxy nanocomposite materials, can solve the problems of insufficient bonding strength of compatible interfaces and insufficient mechanical properties of composite materials to meet requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

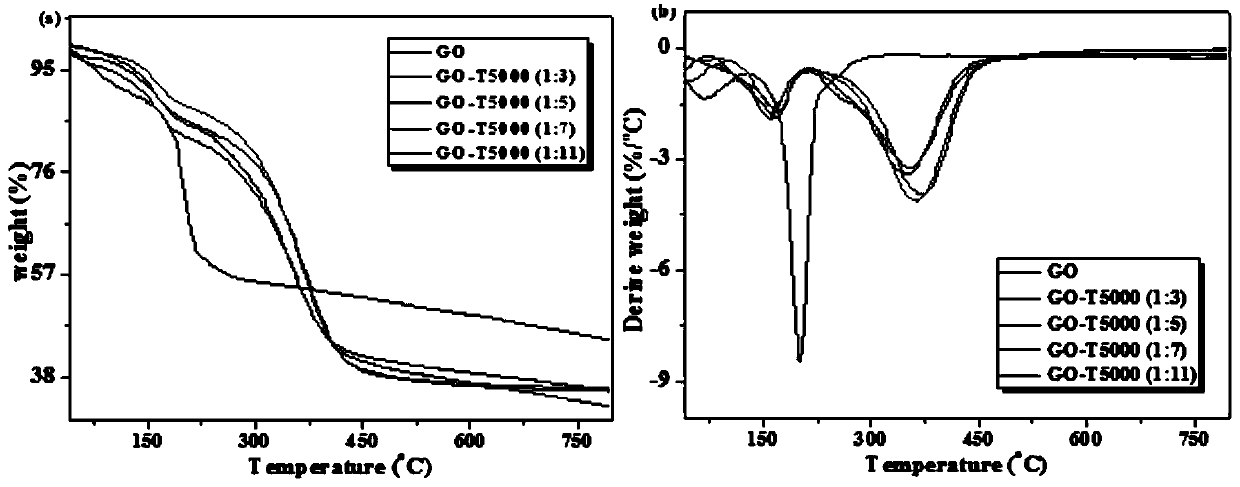

[0034] Embodiment 1, the preparation of polyetheramine modified graphene oxide of the present invention

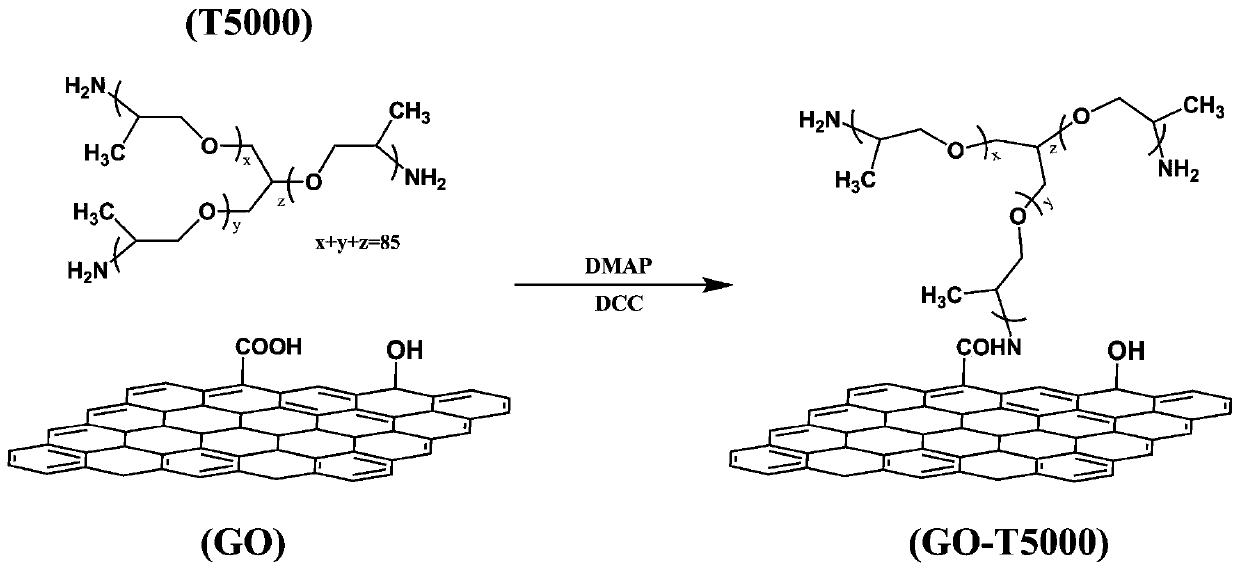

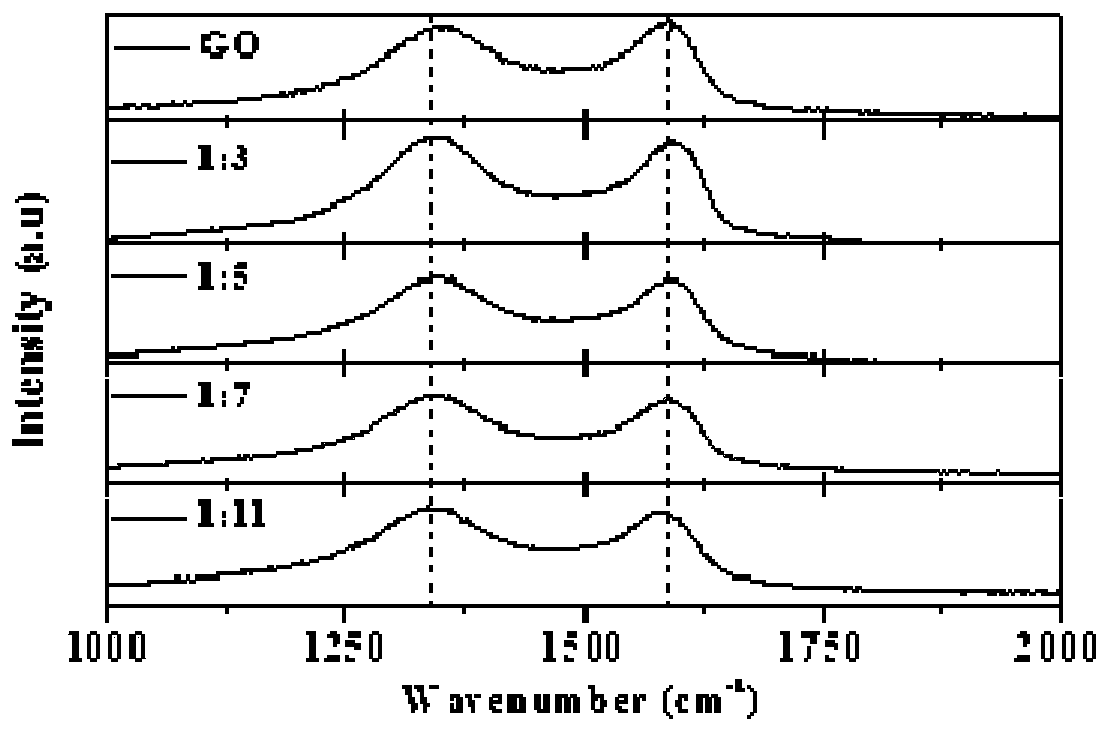

[0035] according to figure 1 The synthetic route shown is to synthesize the polyetheramine-modified graphene oxide (GO-T5000) of the present invention.

[0036] Weigh 0.5g GO (C / O molar ratio is (6.9-7.1): 3, purchased from Beijing Carbon Century Technology Co., Ltd.) and ultrasonically disperse the cells in 500mL dimethylacetamide (DMAC). The suspension was added to a 1000mL three-necked flask, and dimethylaminopyridine (DMAP) and N, N-dicyclohexylcarbodiimide (DCC) were added in sequence, and m(GO):n(DMAP):n( DCC) is 0.5g:5mmol:5mmol. Add polyetheramine T5000 in different proportions (m(GO):n(T5000)=(1:3-1:11) (T5000 was purchased from Shanghai Jingchun Biochemical Technology Co., Ltd.), and stir at a constant speed for 24 hours at 90°C , After the reaction is completed and cooled to room temperature, use a 0.45 μm polytetrafluoroethylene filter membrane to filter und...

Embodiment 2

[0037] Example 2, Preparation of Polyetheramine Modified Graphene Oxide / Epoxy Nanocomposite Material (GO-T5000 / EP) of the present invention

[0038] According to the formula shown in Table 1, weigh the modified graphene oxide GO-T5000, ultrasonically disperse it in the acetone solution at a ratio of 1:1 mg / mL, and add 70 g of TDE-85 epoxy resin to the solution uniformly dispersed after ultrasonic (purchased from Tianjin Jingdong Chemical Composite Material Co., Ltd.), mechanically stirred at 65°C for 14h to remove the solvent. The obtained modified graphene oxide / TDE-85 epoxy resin mixed solution was put into a vacuum oven and dried in vacuum at 65°C until no bubbles were produced in the mixed solution to remove residual solvent. Weigh 4'diaminodiphenylmethane (DDM) and 3,5-diethyl-2,4 toluenediamine (DETDA) mixed curing agent to melt, add modified graphene oxide / TDE-85 epoxy resin mixture In the middle, electric constant speed stirring, so that the curing agent and resin are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com