Transparent epoxy nanometer composite material, preparation method and application thereof

A technology of nano-composite material and transparent ring, applied in the field of transparent epoxy nano-composite material and its preparation, can solve the problems of increased interface force between filler and matrix, decreased light transmittance of material, decreased transmittance of visible light region, etc. The effect of overcoming light scattering phenomena, good fluorescence and phosphorescence effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

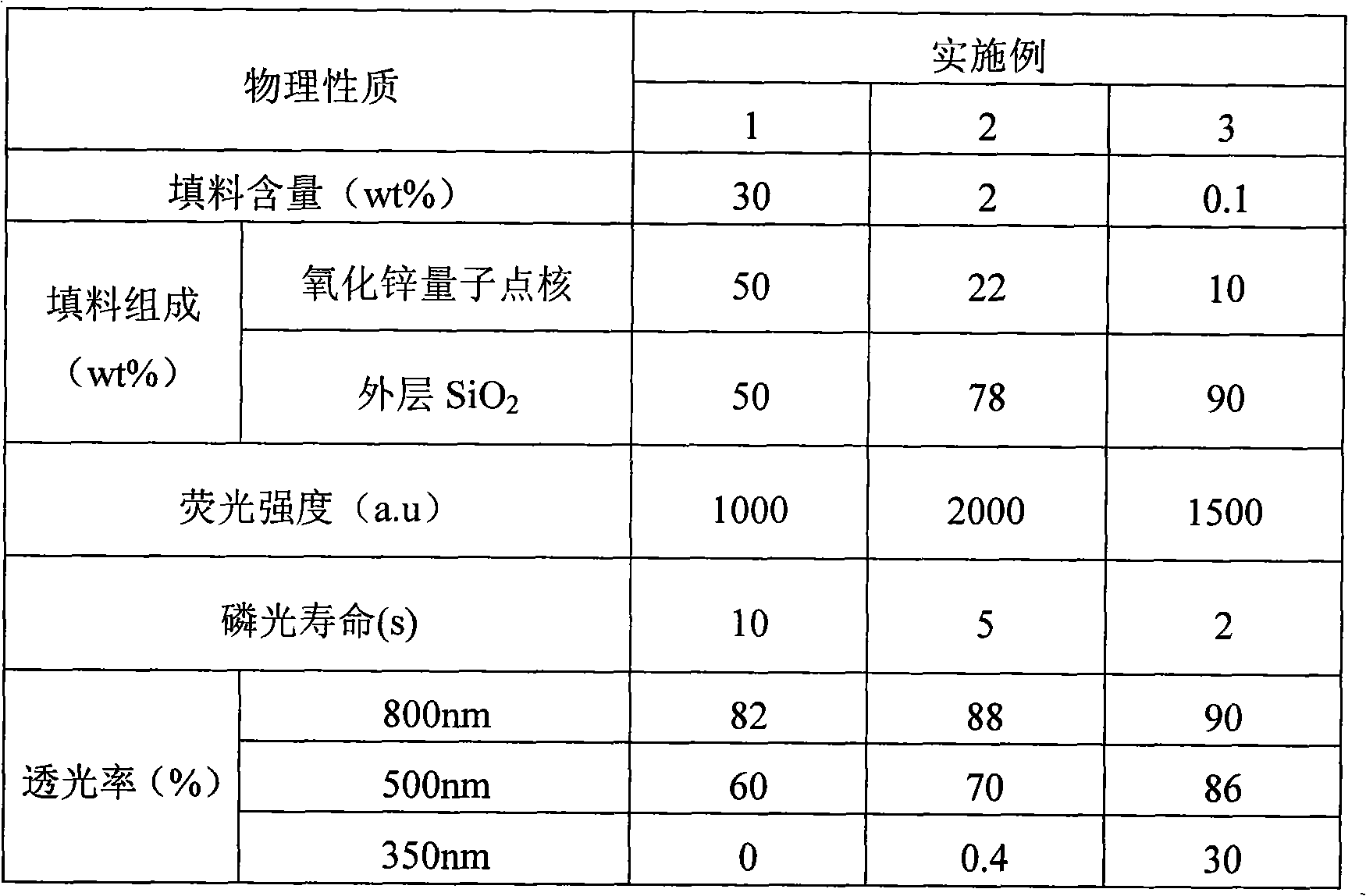

Embodiment 1

[0039] Add 0.0270mol tetraethyl orthosilicate (TEOS) to 200ml ethanol solution (0.1M) containing zinc oxide quantum dots with a particle size of 2nm under stirring, and magnetically stir for 3 hours; Down reaction 16 hours;

[0040] The resulting substance was washed twice with ethanol to obtain a white precipitate; then the resulting white precipitate was dried in air at 80°C for 6 hours, and calcined at 300°C for 0.5 hour to obtain zinc oxide quantum dots with a core / shell structure / Silicon dioxide (ZnO-QD / SiO 2 ) nanocomposite particles;

[0041] The prepared (ZnO-QD / SiO 2 ) Nanocomposite particle 4.3g joins in 6.0g epoxy solidifying agent (hexahydrophthalic anhydride, including 1.0wt% tetraethylammonium bromide) and after dispersing evenly, add 4.0g bisphenol A type epoxy resin (Epon828, DER 331, DER332 or E51), mixed uniformly, injected into the LED mold, cured and molded to obtain the LED encapsulated by transparent epoxy / S-T-S nanocomposite material (filler content is...

Embodiment 2

[0043] Add 0.120mol tetraethyl orthosilicate (TEOS) to 200ml ethanol solution (0.1M) containing zinc oxide quantum dots with a particle size of 6nm under stirring, and magnetically stir for 5 hours; Down reaction 22 hours;

[0044] The resulting material was washed twice by centrifugation with ethanol to obtain a white precipitate; then the resulting white precipitate was dried in air at 80°C for 6 hours, and calcined at 550°C for 1.0 hour to obtain zinc oxide quantum dots with a core / shell structure / Silicon dioxide (ZnO-QD / SiO 2 ) nanocomposite particles;

[0045] The prepared (ZnO-QD / SiO 2 ) Nanocomposite particle 1g joins in the 25g epoxy solidifying agent (methyl hexahydrophthalic anhydride, including 2wt% tetrabutyl ammonium bromide) and after dispersing evenly, add 25g bisphenol A epoxy resin (Epon828, DER 331, DER332 or E51 ). After mixing evenly, pour it into an LED mold, and solidify and shape it to obtain an LED encapsulated by a transparent epoxy / S-T-S nanocomp...

Embodiment 3

[0047] 0.243mol tetraethyl orthosilicate (TEOS) was added under the condition of stirring to 200ml of ethanol solution (0.1M) containing zinc oxide quantum dots with a particle size of 10nm, and magnetically stirred for 8 hours; Down reaction 28 hours;

[0048] The resulting material was centrifuged twice with ethanol to obtain a white precipitate; then the resulting white precipitate was dried in air at 80°C for 6 hours, and calcined at 800°C for 2.0 hours to obtain zinc oxide quantum dots / Silicon dioxide (ZnO-QD / SiO 2 ) nanocomposite particles;

[0049] The prepared (ZnO-QD / SiO 2 ) Nanocomposite particles 0.1g join in 40g epoxy curing agent (methyl hexahydrophthalic anhydride, including 5wt% imidazole, also can replace imidazole with 5wt% 2-methylimidazole), add 60g hydrogenated bis Phenol A epoxy resin (YX8000). After mixing evenly, pour it into an LED mold, and solidify and shape it to obtain an LED encapsulated by a transparent epoxy / S-T-S nanocomposite material (wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com